-

Posts

1,754 -

Joined

-

Last visited

-

Days Won

252

Content Type

Profiles

Forums

Gallery

Everything posted by Xtra

-

Thanks for your interest. I have a lot of work to do before the V3 is ready, and I can't even begin to estimate a cost as it is still in development. I have been working 6 days a week on it. All I can say for sure is keep checking in on this thread for the latest update and as soon as it is ready for production I will post it here.

-

It is as lildisco said. The V2 fits all 2015 to 2018 Edge regardless of model or engine. There might be some European models that I am unaware of that may not be compatible. Otherwise all 2015 to 18 Edges are good to go.

-

Thank you so much MichaelTM, and welcome to the forum. When the air box is finished and tested I will make it available to forum members. Keep checking in as I am updating frequently . There is a ton of great info here for the Ford Edge, here is a thread with a list of mods and links to suppliers that you might be interested in. .

-

What have you done to/with your Edge/MKX today?

Xtra replied to WWWPerfA_ZN0W's topic in Accessories & Modifications

Had no idea that Bilstein was supplying B4 shocks and struts for the ST. I wish that they would make the B8 available for the Edge ST and Sport for use with the H&R springs. . -

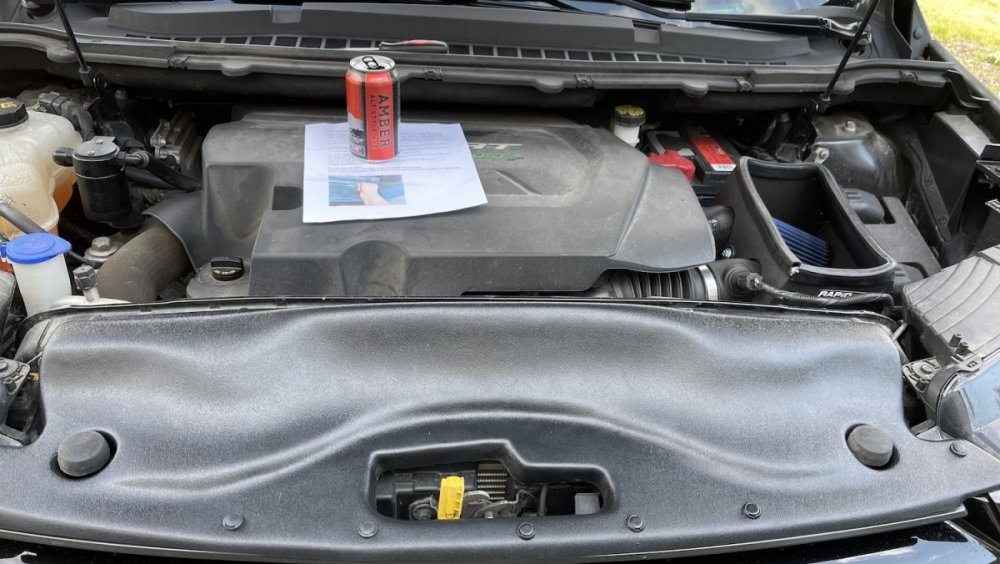

That's great news, looking good . I finally got the fitment bugs worked out with the V2, as it has fit every 2015 to 18 Edged so far. I converted your photo for easier viewing hope you don't mind.

-

For those who ordered an ABS intake they should be arriving by the end of today 05/14. There are two V2 ABS intakes in stock ready to ship that are available right now if anyone is interested. The Carbon Fiber material is still waiting to be manufactured and shipped to me. When it does arrive there will be 2 CF intakes available that have not been spoken for. I will post when it does arrive.

-

Thanks so much, I appreciate it. Enjoy !

-

Started the job of refining the plug, setting the draft angles and fine tuning the fit. There is a lot of messy, dusty, smelly fiberglass work to do before this part of the project is done. . But wait, there's more !! After the vacuum mold is completed for this part, I have to address the snorkel adaptor. But that is another story and will have to wait .

-

What have you done to/with your Edge/MKX today?

Xtra replied to WWWPerfA_ZN0W's topic in Accessories & Modifications

You are going to love those B6 shocked and struts. I assume you are getting both. They work great on my car and have been thoroughly canyon tested. I will never go back to the OEM Shocks and struts. As for the Meth kit I also assume that you have the Rambo cold side pipe with the meth bung hole ... I said bung hole. lol . Anyway, snmjim has been down that road and can give you some vital info on meth injection with the 2.7EB. You should talk to him about it. -

Here is the first look at the bottom half of the V3 with the cardboard part installed. It fits and looks great, and I did it on the first try . I learned so much working on the V2.. After cleaning up the plug it will be ready to transform into a vacuum mold that is compatible with the Vacuum Form Machine. And thats the next step. It was so strange making this part, I had to visualize it to make the plug, and I have no cad 3D program to build it in first. The part uses its backside on the inside of the air box and it is molded from the frontside upside down. I also had to accommodate for the thickness of the ABS in order for the inside of the outside of the part to fit on the outside of the air box. Confusing isn't it? I also had to accommodate the draft angle or taper that exists on a vertical sidewall. It's near-impossible to form plastic over a completely vertical tool and remove the part without issue. ... As the depth or height of the tool increases, the greater the draft angle needs to be. When designing this part I had to insure that there were no negative draft angles and that the positive draft angles are correct in order for the mold to work properly. I could not get around the negative draft angles on my first design and thats why it was abandoned. I like this set up way better anyway.

-

This is the part of the plug that makes the part, the rest is cut away after molding. I made the cardboard part by pressing and gluing cardboard around the plug . This way I can tell if the part will fit.

-

I know that some of you are looking at that plug and thinking " Is that what the bottom half of the V3 looks like? " The short answer to that question is no, it looks nothing like the bottom half. This is to mold a part for the bottom half of the V3. Here is a cardboard copy that is similar to what the real part will look like when made in ABS.

-

It is not much to look at, but the fiberglass plug is cast for the bottom half. It still needs to be finished and converted into a vacuum mold. This came out much better than the V2 did at this same stage of development, so I know it will work and won't have to cast it again.

-

The Edge has an air to air intercooler so it is important to keep the hot under hood air out of the intake system . Liking that Mustang of yours a lot , If you could get a true CAI it would help some, but that liquid cooled intercooler of yours is doing a great job, and Roush know what's up.

-

These are the two different rubber trims that I am considering to seal the snorkel to the air box preventing any hot engine compartment air from entering the V3. OK time for a rant....Several different CAI manufactures leave the top of their air box open allowing for hot under hood air to get into the system. Some use a short pipe connected to a filter with a heat shield on one side relying completely upon hot engine compartment air to feed the system Some try to seal their air box to the underside of the hood in an attempt to have a closed system, this is nothing more than a band-aid for a weak design IMO, and can still let copious amounts of hot air into the system. The V3 is a completely sealed system with a gasket between the top and bottom half of the Air Box. Gaskets are also located at both ends of the snorkel. (Even Ford only uses one gasket at the top of the snorkel.) The V3 filter is sealed and bolted to the air box in such a way as to block any under hood hot air from entering the system. And the filter to the cars accordion pipes are sealed with custom made 6061 aluminum elbow reducers with stainless steel clamps. . When the V3 Air Box is combined with the V2 Intake a completely sealed high performance CAI system will be in place. Something that no other manufacture has done for the Edge 2.7EB. Thanks, I needed to get that off my chest..LOL

-

The blue line is to mark how deep to install the elbow reducers into the accordion tubes on the car for best airflow

-

Was able to get the elbow reducers welded up today. These are the most expensive, but necessary component of the V3. Custom made to fit and flow. Perfect fit . The larger adaptor ring was trimmed in length to free up some space. If you go back a few posts you can see the difference . Large ID, thin wall, smooth curved tubes.

-

Started casting the buck for the bottom half of the V3. Once this is cast I can then transform it into a vacuum form mold. I hope that the casting works works the first time.... unlike the V2 that took three tries to get it close enough to work with LOL. I went to Home Depot to buy the wood for the base and was shocked and unprepared for how much the cost of wood has gone up in the last couple months. With any luck i will finish casting tomorrow and get the elbow reducers welded up as well. At least that is the plan. I am excited about this Air Box project and can't get er' done fast enough .

-

Shipped the ABS V2 intakes. Will be sending PMs with the tracking information later today.

-

I was able to get all the V2 orders packed in their shipping containers, but unfortunately I was too late and FedEx was closed. We have family plans for Sunday so it looks like everything will be shipping on Monday. For those who have ordered an intake I will PM you with the tracking information.

-

When installing elbow reducers for the test fit I realized that I have used every bit of valuable real estate under the hood. I thought it would be a tight fit from the start, but OMG this is ridicules, waste not, want not. lol

-

For those that may have missed my next project, please check out the Air Box that I am working on as a companion for the V2 intake.

-

Test fit the reducers before welding them. Once they are welded, the top half of the V3 will be almost complete. The V3 may look complete in these photos, but there is a ton of work to do on the bottom half. I have to make another vacuum mold for the bottom half and thats just for starters. But this gives a good idea of what the finished air box will look like.

-

Hand fit the ABS intakes today and should be shipping them very soon.

-

Cut the elbow reducer parts to size, and ended up using one 35 and one 45 degree elbow.. Mandrel bent elbow reducers ready for welding