Haz

Edge Member-

Posts

1,476 -

Joined

-

Last visited

-

Days Won

395

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

Welcome to the Forum @ArtdW! Two suggestions from the 2013 Edge Workshop Manual's Engine Noise Vibration Harshness (NV) Symptoms Chart... Engine and transaxle mount images from 2013 Edge Workshop Manual... Remove the transaxle support insulator through bolt and nut. Remove the 3 nuts, the bolt and the transaxle support insulator bracket. Remove the nut, bolt and engine mount brace. Remove the 4 engine mount nuts. Flexplate Inspection procedure from the 2013 Edge Workshop Manual, and Technical instructions from a 2015-2018 2.0L EcoBoost Flexplate cracks inspection Customer Satisfaction Program are attached below as PDF documents... While the Customer Satisfaction Program does not apply to your Edge, due to its model year and its 3.5L Duratec, the technical instructions' imagery and inspection method description may be helpful. Based upon the symptom in the video, and your impression that the noise is coming from the back of the engine, you may want to use a borescope to inspect the Flexplate for cracks. Good luck! Flexplate Inspection - General Procedures - 2013 Edge Workshop Manual.pdf Customer Satisfaction Program 22N12 - 2015-2018 MY 2.0L EcoBoost - Flexplate Inspection Technical Instructions.pdf

-

Special Service Message 51117 - Effective October 4, 2022... SSM 51117 - 2019-2022 Various Vehicles - Illuminated All Wheel Drive (AWD) Warning Indicator Or Fault Message With Certain DTCs Some 2021-2022 Bronco Sport 1.5L, 2019-2022 Edge/Nautilus, 2020-2022 Escape/Corsair, and 2022 Maverick vehicles may exhibit an illuminated AWD warning indicator or fault message with diagnostic trouble code (DTC) C0095:71/:19 stored in the all wheel drive (AWD) module. Some 2021-2022 Bronco Sport 2.0L may exhibit an illuminated AWD warning indicator or fault message with DTC C05D9:71, C05E8:71, C05D8:19 and/or C05E7:19 stored in the AWD module. This may be due to a rear drive unit (RDU) motor magnet ring misalignment. RDU assembly replacement is no longer required. To correct the condition, replace the RDU motor which is now available separately for service. Refer to Workshop Manual, Section 205-02 for diagnosis and repair procedures. For claiming use causal part 4C210 and applicable labor operations in Section 10 of the Service Labor Time Standards (SLTS) Manual. Good luck!

-

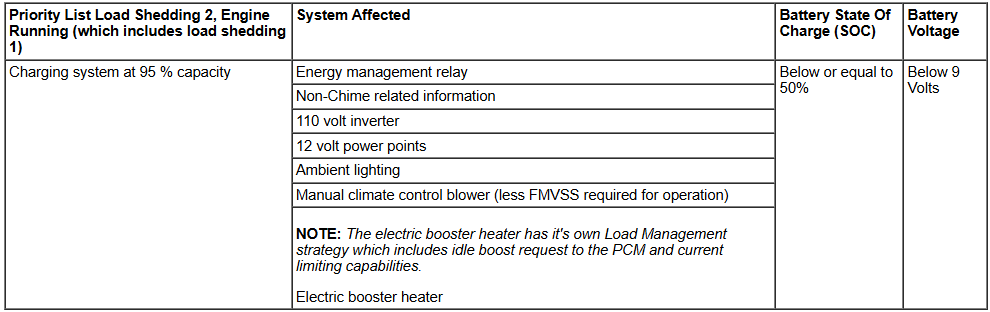

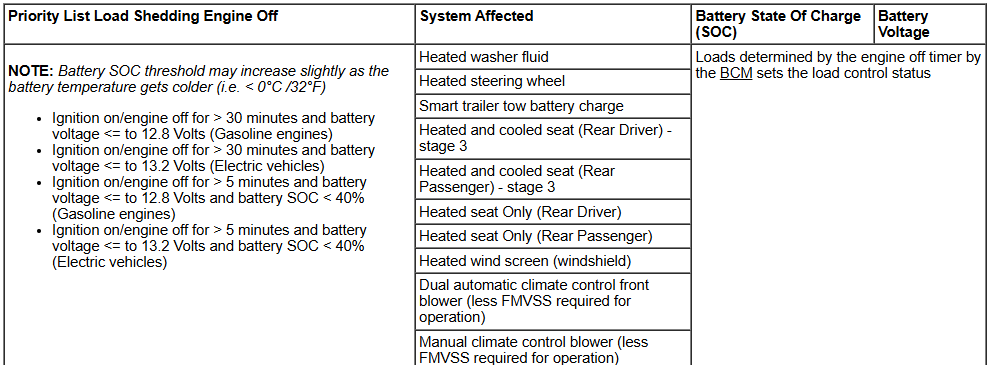

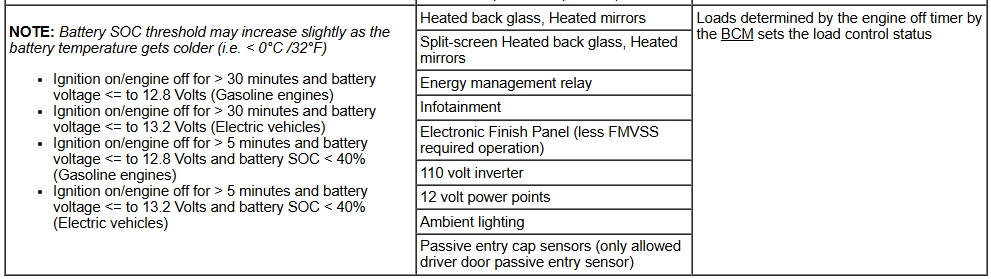

From the 2019 Edge Workshop Manual... Placing your device cursor over underlined acronyms may yield popup full-words descriptions of the acronyms. Battery Load Shed The main purpose of controlling electrical consumption with a load management strategy is to: Limit battery discharge Monitor the battery charge status The alternator is not dimensioned to support all loads in all situations. In some situations energy has to be drawn from the battery. These are mainly during: engine idle cold climate with a lot of electrical heating functions active warm conditions with the engine cooling fan running large transient loads (i.e. EPAS ) During cold conditions, the charge acceptance of the battery is very low which increases the time needed to recharge the battery. This means that it can take up to several hours of driving before the battery is recharged. The electrical consumption control is using Ignition_Status, Remote_Start_Status and EngineStateInternal in order to define the load management strategy during the different operating states of the vehicle. The BCM is the primary module that is responsible for controlling the load management strategy. The BCM processes measurements of the system and uses the information for calculations and load prioritization The strategy allows drain to occur from the battery. Load Management minimizes the drain by controlling the time and magnitude of the drain that can occur. The battery drain changes depending on the driving cycle and the types of loads the driver has activated, therefore, the BCM must be able to shut down or reduce the loads if necessary. The intent of the initial load shed stage, LSHED1, is to reduce electrical loads in a manner that is not noticed by the vehicle operator. During LSHED1, requests are sent in a prioritized order for the appropriate modules to begin shedding available loads. In order to prevent customer satisfaction issues, the loads are requested to reduce power consumption with minimum impact to the customer. The second load shed event, LSHED2, occurs in two stages, SHED2_TRANS and SHED2_CONTIN. During operation of a vehicle equipped with large transient loads, there are transient peaks for current draw. The Load Management algorithm reacts to these spikes by using the SHED2_TRANS state. This state requires all non-critical loads to shed immediately, without customer indication, so that large transient loads can operate normally with little to no adverse impact to the customer. SHED2_CONTIN is a continuous deactivation of the loads to ensure the vehicle is able to re-start once the ignition is turned off. During SHED2_CONTIN, a message is displayed to the vehicle operator notifying them of the vehicle's charging system status. Independent of load shed requests, the Load Management control can request boosts to the engine idle speed. Boosting the engine idle speed allows for increased output of the alternator to deliver more current to the battery. Idle speed increases are done through network IBoost messages. The load shed charts provide a general overview of the features available on the vehicle based on the build options. Load Shed Charts Priority List Load Shedding 1 Priority List Load Shedding 2 Priority List Load Shedding Engine Off Good luck! Battery Load Shed - Description and Operation - 2019 Edge Workshop Manual.pdf

-

I was similarly curious, especially given the same document's inclusion in the 2021 Edge Workshop Manual, with the same Procedure Revision Date of October 22, 2024. It's likely an editorial oversight, since lacking side view cameras, it seems only a historical strip of peripheral front camera images would be available for stitching into a time-lapsed view of what has been on either side of the vehicle, rather than a live view of what presently exists. Good luck!

-

If your Edge is not equipped with Automatic Headlamp Leveling... The mid and high series headlamps may be equipped with automatic headlamp leveling. The headlamp beam height is automatically adjusted according to vehicle load, speed, acceleration and braking. Automatic headlamp leveling is activated when the headlamp switch is in the HEADLAMPS or AUTOLAMPS position. ...then it may be Connector C2129 for the Headlamp Control Module (HCM), which is only installed on vehicles equipped with automatic headlamp leveling... Good luck! Headlamp Control Module (HCM) - Connector C2129 Pinout - 2021 Edge.pdf

-

From the 2021 Edge Wiring Resource... Good luck! Inline Connector C133 - Circuit ID Pinout - 2021 Edge.pdf Inline Connector C133 - Location - 2021 Edge.pdf Inline Connector C139 - Circuit ID Pinout - 2021 Edge.pdf Inline Connector C139 - Location - 2021 Edge.pdf Inline Connector C212 - Circuit ID Pinout - 2021 Edge.pdf Inline Connector C212 - Location - 2021 Edge.pdf Inline Connector C213 - Circuit ID Pinout - 2021 Edge.pdf Inline Connector C213 - Location - 2021 Edge.pdf Inline Connector C408 - Circuit ID Pinout - 2021 Edge.pdf Inline Connector C408 - Location - 2021 Edge.pdf Inline Connector C411 - Circuit ID Pinout - 2021 Edge.pdf Inline Connector C411 - Location View #1 - 2021 Edge.pdf Inline Connector C411 - Location View #2 - 2021 Edge.pdf

-

Help - Code: C1039:94-0A Active Front Steering (AFS) Lock

Haz replied to al303's topic in Brakes, Chassis & Suspension

Adding High Current Battery Junction Box (BJB) information... This BJB exploded view illustration might be useful toward locating: Good luck! High Current Battery Junction Box (BJB) - Illustration - 2018 Edge.pdf High Current Battery Junction Box (BJB) - Location View #1 - 2018 Edge.pdf High Current Battery Junction Box (BJB) - Location View #2 - 2018 Edge.pdf High Current Battery Junction Box (BJB) - Wiring Diagram - 2018 Edge.pdf High Current Battery Junction Box (BJB) - Connector C1617G [to F1 (40 Amp)] Detail - 2018 Edge.pdf BJB Exploded View Illustration - FordParts_com.pdf -

Help - Code: C1039:94-0A Active Front Steering (AFS) Lock

Haz replied to al303's topic in Brakes, Chassis & Suspension

@al303: To emphasize the importance of your Health and Safety awareness, the SRS Depowering and SRS Repowering procedures are included here and are also provided below as PDF documents, as is a general Pyrotechnic Device Health and Safety Precautions document... Work safely! Supplemental Restraint System (SRS) Depowering - General Procedures - 2018 Edge Workshop Manual.pdf Driver Airbag - Vehicles With Adaptive Steering - Removal and Installation - 2018 Edge Workshop Manual.pdf Pyrotechnic Device Health and Safety Precautions - General Procedures - 2018 Edge Workshop Manual.pdf Battery Disconnect and Connect - General Procedures - 2018 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Repowering - General Procedures - 2018 Edge Workshop Manual.pdf Adaptive Steering - SECM Wiring Diagram - 2018 Edge.pdf STEERING EFFORT CONTROL MODULE (SECM) - Connectors C2391A, C2391B, C2391C Location - 2018 Edge.pdf STEERING EFFORT CONTROL MODULE (SECM) - Connectors C2391A Pinout - 2018 Edge.pdf STEERING EFFORT CONTROL MODULE (SECM) - Connectors C2391B Pinout - 2018 Edge.pdf STEERING EFFORT CONTROL MODULE (SECM) - Connectors C2391C Pinout - 2018 Edge.pdf CLOCKSPRING-STEERING ANGLE SENSOR MODULE (SASM) - Connector Locations - 2018 Edge.pdf STEERING EFFORT CONTROL MODULE (SECM) - Ground G200 Location - View #1 - 2018 Edge.pdf STEERING EFFORT CONTROL MODULE (SECM) - Ground G200 Location - View #2 - 2018 Edge.pdf Steering Column Shrouds - Removal and Installation - 2018 Edge Workshop Manual.pdf -

Welcome to the Forum,@longbeachbob! No modifying Supplement to Emission Recall 24E10 has been posted to Ford's Professional Technician System (PTS) website, thus far. If the affected vehicle population was being modified, a Supplement would be issued and/or if a pause in the Field Service Action was occurring, a notification would be posted to PTS. If either of these announcements are made, I will post them here and to the original announcement. Congrats on your Edge's successful smog test. Was it a Basic Test with OBDII connection and tailpipe probe, or does your location require the Enhanced Test that included your Edge running on a dyno during sampling? Good luck!

-

With emphasis added... SSM 53280 - 2024 Nautilus - Driver Seat And Steering Column Not Moving To Easy Entry Position After Setting Up A Client Profile Some 2024 Nautilus vehicles may exhibit a concern with the driver seat and steering column moving to the saved memory position instead of the easy entry position when approaching or unlocking the vehicle with the key fob. This condition may occur after setting up a client profile and is due to the driver front seat module (DSM) software. Inform customers that they can continue to drive the vehicle and that engineering is currently working on revised DSM software for this condition that is expected Q1 2025. In the interim, easy entry will function if the key fob is unlinked from the customers personal profile by selecting the profile on the center display screen, pressing the edit icon, choosing ID Method, pressing Unlink Key Fob, and then selecting Unlink from the pop-up screen. The customers driver seat and steering column memory settings will no longer be saved to the key fob but can be recalled by using the memory switches on the door or on the center display screen. Monitor PTS for additional information and schedule service appointments for customers once the repair becomes available. This Special Service Message 53280 has also been posted on Ford's Canadian Professional Technician System (PTS) website.

-

Help - Code: C1039:94-0A Active Front Steering (AFS) Lock

Haz replied to al303's topic in Brakes, Chassis & Suspension

@al303: Excerpts from 2018 Edge Workshop Manual, with emphasis added, and full sections attached below as PDF documents... Placing your device cursor over underlined acronyms may yield full-words descriptions of the acronyms. Adaptive Steering Overview The adaptive steering system provides steering assist to the driver by dynamically changing the steering ratio between the steering wheel and the road wheels, thereby reducing the number of steering wheel turns required to turn the road wheels. This is accomplished through the use of a motor, worm gear and toothed hub. All adaptive steering system components are inside the steering wheel, behind the driver air bag. Adaptive Steering System The SECM is self-monitoring and is capable of setting and storing Diagnostic Trouble Codes (DTCs). Depending on the nature of the DTC , the SECM may engage the adaptive steering lock and may send a request to the IPC to illuminate the adaptive steering system warning indicator and display a message in the message center alerting the driver of a potential adaptive steering system concern. The warning message is sent over the HS-CAN2 to the GWM where it is converted to a HS-CAN3 message and forwarded on to the IPC over the HS-CAN3 . Adaptive Steering Lock The adaptive steering system is designed with a locking device. While the lock is engaged, the steering system is set to a fixed (1:1) steering ratio. A sound may be heard when the vehicle is started or shut off as the lock is disengaged or engaged and a slight movement of the steering wheel may be noticed while the locking action is taking place. If the vehicle loses electrical power or the SECM detects a fault while driving, the lock is engaged. Extreme operating conditions may also cause the SECM to engage the lock. This strategy prevents overheating and permanent damage to the adaptive steering system. Typical steering and driving maneuvers allow the system to cool and return to normal operation. While the lock is engaged, it is possible the steering wheel may not be straight when the vehicle is driving straight ahead and the driver may notice the steering wheel angle or "clear vision" may be off-set. The locking solenoid also engages when the ignition is set to ON and the driver door is closed, this prevents the steering wheel from turning unnecessarily while the system is off and affecting steering wheel clear vision. The locking solenoid disengages once the engine is started. Adaptive Steering System - Diagnosis and Testing PINPOINT TEST K: STEERING LOCK CONCERN Introduction Normal Operation and Fault Conditions With the ignition ON, the SECM monitors various inputs to detect if a fault is present. DTC Fault Trigger Conditions DTC Description Fault Trigger Condition C1039:7F Active Front Steering (AFS) Lock: Actuator Stuck Off Sets when the SECM cannot activate the adaptive steering lock at engine start. C1039:92 Active Front Steering (AFS) Lock: Performance Or Incorrect Operation Sets when the SECM detects the adaptive steering lock fails the unlocking test. C1039:94 Active Front Steering (AFS) Lock: Unexpected Operation Sets when the SECM detects the adaptive steering lock fails the integrity test or the locking disc calibration test. C200D:28 Motor Rotation Angle Sensor: Signal Bias Level Out Of Range/Zero Adjustment Failure Sets when the SECM detects the adaptive steering motor angle sensor signal is outside the normal operating range or if the sensor is incapable of learning the center position. C200D:62 Motor Rotation Angle Sensor: Signal Compare Failure Sets when the SECM detects the adaptive steering motor angle sensor fails to learn the center position. U2001:92 Reduced System Function: Performance Or Incorrect Operation Sets due to a restraint airbag impact event or a fuel cutoff event. Due to the fault setting conditions, the installation of a new steering wheel and SECM are not covered under the vehicle warranty. Subsequently, a RVC is not provided for component replacement due to this DTC. U3000:46 Control Module: Calibration/Parameter Memory Failure Sets when the SECM detects an internal fault. U3000:49 Control Module: Internal Electronic Failure Sets when the SECM detects an internal fault. U3000:61 Control Module: Signal Calculation Failure This DTC sets due to an incomplete or an improperly performed trim routine. U3000:9A Control Module: Component or System Operating Conditions Sets when the SECM detects an internal fault. Possible Causes Incorrect sensor input SECM (steering wheel) K1 CARRY OUT THE SASM (STEERING ANGLE SENSOR MODULE) MODULE RESET ROUTINE NOTE: If present in any module, diagnose DTC U3003:16, U3003:1C or U3003:68 before diagnosing DTC C1039:7F, C1039:92 or U3000:49. Ignition ON. Using a diagnostic scan tool, carry out the SASM Module Reset routine. No VCM Recognized Ignition OFF. Start the engine and wait 20 seconds for the SECM to wake up and test the adaptive steering system. Ignition ON. No VCM Recognized Is the original DTC from the DTC Fault Trigger Conditions table retrieved again? Yes GO to K2. No For all other DTCs , REFER to the SECM DTC Chart. If no DTCs are present, the concern is not present and the system is operating correctly at this time. K2 CHECK FOR SASM (STEERING ANGLE SENSOR MODULE) DTCS No VCM Recognized Are any SASM DTCs present? Yes DIAGNOSE the DTCs present. REFER to Section 206-09 in the Workshop Manual. No GO to K3. K3 VERIFY ALL WIRING CONNECTIONS Ignition OFF. Disconnect all SECM electrical connectors. Using a good light source, inspect all disconnected electrical connectors for the following: corrosion - install new connector or terminal and clean the module pins damaged or bent pins - install new terminals or pins pushed-out pins - install new pins as necessary spread terminals - install new terminals as necessary Are the connectors free of corrosion, damaged pins, bent pins, pushed-out pins and spread terminals? Yes For all others: GO to K4. No REPAIR the connector or terminals. Refer to Wiring Diagrams Cell 5 for schematic and connector information. K4 CHECK FOR CORRECT SECM (STEERING EFFORT CONTROL MODULE) OPERATION Connect all SECM electrical connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes INSTALL a new Steering Wheel (SECM) assembly. CHECK OASIS for any applicable service articles: TSBs , GSB, SSM#2 or FSA. If a service article exists for this concern, DISCONTINUE this test and FOLLOW the service article instructions. If no service articles address this concern, INSTALL a new SECM (part of the steering wheel). REFER to Section 211-04 in the Workshop Manual. Generate RVC only works in single-step view No The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS the root cause of any connector or pin issues. K5 CHECK FOR CORRECT SECM (STEERING EFFORT CONTROL MODULE) OPERATION Connect all SECM electrical connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes INSTALL a new Steering Wheel (SECM) assembly. CHECK OASIS for any applicable service articles: TSBs , GSB, SSM#2 or FSA. If a service article exists for this concern, DISCONTINUE this test and FOLLOW the service article instructions. If no service articles address this concern, INSTALL a new SECM (part of the steering wheel). REFER to Section 211-04 in the Workshop Manual. No The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS the root cause of any connector or pin issues. If you're inclined toward fuller do-it-yourself efforts to resolve the issue, I can provide additional procedures and resources, otherwise this provides you a glimpse at what a professional technician at the dealership or an independent repair facility may be considering. Link to this FordParts webpage Good luck! Adaptive Steering - Overview - 2018 Edge Workshop Manual.pdf Adaptive Steering - System Operation and Component Description - 2018 Edge Workshop Manual.pdf PINPOINT TEST K - STEERING LOCK CONCERN - Diagnosis and Testing - 2018 Edge Workshop Manual.pdf Steering Wheel - Vehicles With Adaptive Steering - Removal and Installation - 2018 Edge Workshop Manual.pdf -

Weird acting rear light…

Haz replied to FLvet85's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

The PDF documents attached below may be useful supplements to the information @Wubster100 has shared... Good luck! Rear Turn Signal-Stop-Hazard Lamps, Low Series - Wiring Diagram - 2016 Edge.pdf Rear Turn Signal-Stop-Hazard Lamps, High Series - Wiring Diagram - 2016 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280D Pinout - 2016 Eddge.pdf BODY CONTROL MODULE (BCM) - Connector C2280D Location - 2016 Eddge.pdf BODY CONTROL MODULE (BCM) - Connector Locatio Illustration - 2016 Eddge.pdf REAR LAMP ASSEMBLY LH - Connector C412 Pinout - 2016 Edge.pdf REAR LAMP ASSEMBLY RH - Connector C415 Pinout - 2016 Edge.pdf -

Good luck! Parking Aid - 360 Degree View Camera Alignment - 2020 Nautilus Workshop Manual.pdf Parking Aid - 360 Degree Camera - 2020 Nautilus Owner's Manual.pdf Parking Aid - 180 Degree Camera - 2022 Edge Owner's Manual.pdf

-

@Wubster100: Relevant information from 2020 Nautilus and 2022-2024 Edge Owner's Manuals, Workshop Manuals, and Wiring Resources, is attached as PDF documents below and in an immediately following post, due to Forum file attachment limitations... Touchscreen WITH Front Split View Camera - APIM & IPMB Wiring Diagram - 2022-2024 Edge.pdf Rear View Camera - Touchscreen WITHOUT Front Split View Camera - Wiring Diagram - 2022-2024 Edge.pdf APIM Module Communications - Wiring Diagram #1 - 2022-2024 Edge.pdf APIM Module Communications - Wiring Diagram #2 - 2022-2024 Edge.pdf APIM & IPMB Grounds - Wiring Diagram - 2022-2024 Edge.pdf APIM Power Distribution - Wiring Diagram - 2022-2024 Edge.pdf SYNC MODULE (APIM) - Connector C2383A Pinout - 2022-2024 Edge.pdf SYNC MODULE (APIM) - Connector C2383F Pinout - 2022-2024 Edge.pdf IMAGE PROCESSING MODULE B (IPMB) - Connector C3676A Pinout - 2022-2024 Edge.pdf IMAGE PROCESSING MODULE B (IPMB) - Connector C3676B Pinout - 2022-2024 Edge.pdf IMAGE PROCESSING MODULE B (IPMB) Module Communications - Wiring Diagram - 2022-2024 Edge.pdf Rear View Camera - Touchscreen WITH Front Split View Camera - IPMB Wiring Diagram - 2022-2024 Edge.pdf Front Split View Camera - Power Distribution & IPMB Wiring Diagram - 2022-2024 Edge.pdf AUDIO CONTROL PANEL (Front Camera Switch) - Connector C2009 Pinout - 2022-2024 Edge.pdf AUDIO CONTROL PANEL (Front Camera Switch) - APIM & HVAC Wiring Diagram - 2022-2024 Edge.pdf HVAC MODULE - Connector C228B Pinout - 2022-2024 Edge.pdf Parking Aid - Overview - 2022-2024 Edge Workshop Manual.pdf Parking Aid - Component Location - 2022-2024 Edge Workshop Manual.pdf Parking Aid - System Operation and Component Description - 2022-2024 Edge Workshop Manual.pdf Parking Aid - 360 Degree View Camera Alignment - 2022-2024 Edge Workshop Manual.pdf Image Processing Module B (IPMB) - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf 360 Camera - Wiring Diagram #1 - 2020 Nautilus.pdf 360 Camera - Wiring Diagram #2 - 2020 Nautilus.pdf 360 Camera - Wiring Diagram #3 - 2020 Nautilus.pdf 360 Camera - Wiring Diagram #4 - 2020 Nautilus.pdf IMAGE PROCESSING MODULE B (IPMB) - Connector C3676B Pinout - 2020 Nautilus.pdf IMAGE PROCESSING MODULE B (IPMB) - Connector C3676A Pinout - 2020 Nautilus.pdf EXTERIOR MIRROR LH - Connector C517 Pinout - 2020 Nautilus.pdf EXTERIOR MIRROR RH - Connector C615 Pinout - 2020 Nautilus.pdf Parking Aid - Component Location - 2020 Nautilus Workshop Manual.pdf Parking Aid - Overview - 2020 Nautilus Workshop Manual.pdf Parking Aid - System Operation and Component Description - 2020 Nautilus Workshop Manual.pdf Side Parking Aid Camera - Removal and Installation - 2020 Nautilus Workshop Manual.pdf

-

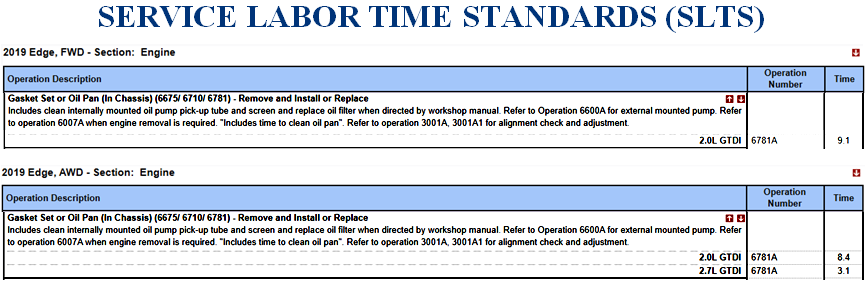

Labor hours to replace an oil pan.

Haz replied to rjburer's topic in Dealership & Vendor Experiences

Oil Pan - Removal and Installation - 2.0L EcoBoost - 2019 Edge Workshop Manual.pdf Transmission - Removal and Installation - 2.0L EcoBoost - 2019 Edge Workshop Manual.pdf Good luck! -

From the 2020 Edge Workshop Manual, with emphasis added... Spare Tire And Mismatched Tire Sizes Major dissimilar tire sizes between the front and rear axles could cause the AWD system to stop functioning and default to FWD or damage the AWD system. It is recommended to reinstall a repaired or replaced road tire as soon as possible. When a mismatched or tire of the wrong size is fitted, an AWD OFF message may appear in the IPC . If this condition occurs, a DTC is set and an AWD OFF message is displayed on the message center. If there is an AWD malfunction service required message in the message center from using a spare or mismatched tire, this indicator should turn off after reinstalling a tire of the same size as the normal road tire, then cycling the ignition OFF and ON. Good luck!

-

@TourGuide: The content of 2.7L EcoBoost PTU documents is identical to the above-posted 2.0L EcoBoost versions. I saw 2.0L Forum posts on your Profile and just assumed -- and we all know what that makes me! Good luck!

-

@TourGuide: Information on your Edge's PTU from the 2019 Edge Workshop Manual. attached below as PDF documents... Good luck! Power Transfer Unit (PTU) Draining and Filling - 2.0L EcoBoost - General Procedures - 2019 Edge Workshop Manual.pdf Power Transfer Unit (PTU) - 2.0L EcoBoost - Description and Operation - 2019 Edge Workshop Manual.pdf Power Transfer Unit (PTU) - 2.0L EcoBoost - Specifications - 2019 Edge Workshop Manual.pdf Power Transfer Unit (PTU) Fluid Level Check - 2.0L EcoBoost - General Procedures - 2019 Edge Workshop Manual.pdf

-

@STBEAST: PTU Description and Operation section for 2.7L EcoBoost, from the 2022-2024 Edge Workshop Manual, attached below as PDF document... Good luck! Power Transfer Unit - Description and Operation - 2.7L EcoBoost - 2022-2024 Edge Workshop Manual.pdf

-

Welcome to the Forum @mskotlarek1, and thank you for raising up your courageous daughter who is among the valiant Airmen who represent our country's strength around the world! We are indebted to your daughter, yourself, and the rest of your family for the sacrifices you all make on our behalf. A good first step toward resolving the throttle control issue on your daughter's Edge can be having the vehicle's electronic modules scanned for Diagnostic Trouble Codes (DTCs), which provide guidance toward subsequent diagnostic efforts to determine the throttle control issue's root cause. If you don't have a Code Reader device immediately available to you, consider calling around to Auto Parts stores nearby and ask about their capability (and any cost) of performing a DTC scan on the Edge, with them providing you a list of the any DTC(s) found. Please report any found DTC(s) back here, and we'll offer you fuller advice, which can include diagnostic and repair procedures -- if you are interested and equipped to attempt those next-steps yourself, as opposed to having a professional technician at a nearby dealership or an independent repair shop address the repair. It seems likely your daughter's Edge is a United States-market vehicle that she has repatriated following her buying it in Italy, but if the Edge was originally an EU-market vehicle, please let us know. Once again, thank you for your daughter's Service. Good luck!

-

To emphasize the importance of your Health and Safety awareness, the SRS Depowering and SRS Repowering procedures are included here and are also provided below as PDF documents... From the Workshop Manual's Anti-Lock Brake System (ABS) and Stability Control section, with emphasis added... Stability Control Sensors The stability control sensors for the vehicle dynamic system consist of the yaw rate sensor, lateral accelerometer, longitudinal accelerometer and roll rate sensor. The sensors are housed in the RCM which sends sensor information to the ABS module over the HS-CAN2 . If any of the sensors are defective, a new RCM must be installed. The yaw rate sensor measures the yaw angle which is the difference between the direction the vehicle is pointing when cornering and the direction the vehicle is actually moving. The longitudinal accelerometer measures the acceleration and deceleration of the vehicle as it moves forward and backward. The lateral accelerometer measures the force created when a vehicle corners that tends to push a vehicle sideways. The roll rate sensor measures the rate of rotation of the vehicle along the centerline of the vehicle from front to back. Lateral acceleration has 2 forms. The first is the centrifugal acceleration that is generated when the vehicle travels around in a circle. The second is the acceleration due to gravity. On level ground there is no lateral acceleration due to gravity. However, if the vehicle is parked sideways on a bank or incline, the sensor measures some lateral acceleration due to gravity, even though the vehicle is not moving. A professional dealership technician may use Ford Diagnostic and Repair System (FDRS) diagnostic scan tool connected to Ford's servers to likely run a VIN-specific Guided Routine (RCM) of PINPOINT TEST AG: STABILITY CONTROL SENSOR EVENT INFORMATION FAULTS (C006X:68) to determine if replacement of the RCM is indicated by the step-by-step Pinpoint Test results. Work safely. Supplemental Restraint System (SRS) Depowering - General Procedures - 2018 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) - Wiring Diagram 1 - 2018 Edge.pdf RESTRAINTS CONTROL MODULE (RCM) - Connector C310 Pinout - 2018 Edge.pdf RESTRAINTS CONTROL MODULE (RCM) - Connector C310 Location - 2018 Edge.pdf BATTERY ENERGY CONTROL MODULE B (BECMB) - Connector C2518 Pinout - 2018 Edge.pdf BATTERY ENERGY CONTROL MODULE B (BECMB) - Connector C2518 Location - 2018 Edge.pdf Supplemental Restraint System (SRS) - Wiring Diagram 2 - 2018 Edge.pdf OCCUPANT CLASSIFICATION SYSTEM MODULE (OCSM) - Connector C3043 Pinout - 2018 Edge.pdf OCCUPANT CLASSIFICATION SYSTEM MODULE (OCSM) - Connector C3043 Location - 2018 Edge.pdf OCCUPANT CLASSIFICATION SYSTEM MODULE (OCSM) - Removal and Installation - 2018 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Repowering - General Procedures - 2018 Edge Workshop Manual.pdf Gateway Module - Power Distribution Wiring Diagram - 2018 Edge.pdf

-

From the 2007 MKX Workshop Manual... Good luck! Anti-Theft NOTE: The smart junction box (SJB) is also known as the generic electronic module (GEM). The passive anti-theft system (PATS) consists of the following components: Anti-theft indicator (located in the instrument cluster [IC]) Encoded ignition integrated keyhead transmitter (IKT) PATS key(s) (the key contains a transponder and a remote keyless entry [RKE] transmitter) Encoded (the key contains a transponder) ignition PATS keys (not factory equipped, but may be used in place of IKT keys) PATS transceiver IC PCM PATS uses radio frequency identification technology to deter a drive-away theft. Passive means that it does not require any activity by the user. The vehicle is equipped with 2 IKT PATS keys. The IKTs operate as a standard PATS key with an RKE transmitter incorporated into the keyhead. The IKTs require batteries for the RKE transmitter to operate. A maximum of 4 IKT keys can be programmed to operate the vehicle. If more than 4 IKT keys are programmed, the RKE portion of the additional keys do not operate and the SJB and the IC set a memory full DTC (B1138 — Memory Full). These additional keys will start the vehicle, but will not operate the RKE system. If additional PATS keys are desired, a standard PATS key (a non-IKT key) can be used. For the purposes of this section, the PATS portion of the IKT key is referred to as a PATS key. PATS Function NOTE: If the IC or the PCM (or both) is replaced, the parameters must be re-set in both modules or the vehicle will experience a PATS no-start. Refer to Passive Anti-Theft System (PATS) Parameter Reset in this section. The PATS function is controlled by the IC. The PATS uses the IC to carry out all of the PATS functions such as receiving the identification code from the PATS key, issuing a signal to the PCM to control the starter and fuel injectors enable, and initiating the key interrogation sequence when the ignition key is turned to the ON or START position. Because of the interaction between the IC and the PCM, there are parameters that must be set if the IC or the PCM (or both) are replaced. Refer to Passive Anti-Theft System (PATS) Parameter Reset in this section. If the IC must be replaced for any reason (PATS concerns or an IC concern), the PATS keys also must be programmed into the new IC. Refer to Integrated Keyhead Transmitter (IKT) Key Programming Using Diagnostic Equipment in this section. All elements of PATS must be functional before the vehicle will start. If any of the components are not working correctly, the vehicle will not start. PATS is active only for a few seconds when the vehicle is starting. It is not a PATS concern if the vehicle stalls after it has been running for a minimum of 3 seconds. PATS will not disable a running vehicle. PATS may cause a vehicle no start due to either the fuel injectors or the starter not operating (starter relay does not close) or both. Always check for PATS DTCs from the IC and DTCs from the PCM when a no-crank or no-start condition exists. A low state of charge (SOC) in the vehicle battery may cause the PATS to allow starter operation, but prevent the fuel injectors from operating. If the theft light does not prove out (it may be either flashing or glowing steadily) and one (or both) of the previous conditions (fuel injectors and/or starter inoperative) are present, it may be due to a PATS issue. If the theft light proves out, it may not be a PATS issue. If the theft light does not illuminate at all, it may be an IC issue. GO to Symptom Chart. PATS is not compatible with aftermarket remote start systems, which allow the vehicle to be started from the exterior of the vehicle. These systems may reduce the security of the vehicle, and also may be the cause of no-start concerns. Remote start systems must be removed from the vehicle before any PATS-related no-start concerns are investigated.

-

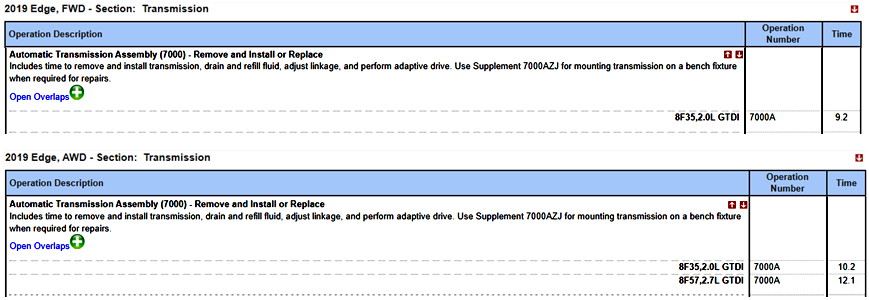

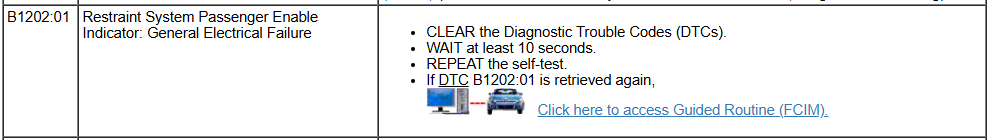

Welcome to the Forum @99jhawk! Introductory diagnostic descriptions from the 2018 Edge Workshop Manual for most of your Edge's listed Diagnostic Trouble Codes (DTCs) are shown below... I was unable to immediately locate B005:01-28, U3000:4A-28, and U2300:64-28 without knowing the module(s) exhibiting the DTC(s). Regardless of those three DTCs, your intuition to leave the diagnostic & repair tasks to a professional dealership technician is valid, based upon the general caution Ford offers when dealing with Supplemental Restraint System (SRS) issues: WARNING: Incorrect repair techniques or actions can cause an accidental SRS deployment. Never compromise or depart from these instructions. Failure to precisely follow all instructions could result in serious personal injury from an accidental deployment. Good luck! Placing your device cursor over underlined acronyms may yield popup full-words descriptions of the acronyms. PINPOINT TEST L: OCS FAULTS REPORTED BY RCM Introduction Normal Operation and Fault Conditions The RCM is in constant communication with various control modules on the HS-CAN 2. One of those modules is the OCSM . The RCM continuously monitors the HS-CAN 2 for fault messages reported by the OCSM . The RCM also checks for the correct identification of the OCSM . If the RCM receives fault message(s) from the OCSM , it stores DTC B00A0:09, B00A0:4A, B00A0:63, B00A0:64 or B00A0:68 in memory and sends a message to the IPC to illuminate the airbag warning indicator. DTC Fault Trigger Conditions DTC Description Fault Trigger Condition B00A0:09 Occupant Classification System: Component Failure Sets when the RCM receives a message from the OCSM that a fault exists within the OCS. B00A0:4A Occupant Classification System: Incorrect Component Installed Sets when the RCM senses the OCSM is present but not configured. B00A0:63 Occupant Classification System: Circuit/Component Protection Time-Out Sets when the RCM receives 8 or more invalid states from the OCSM. B00A0:64 Occupant Classification System: Signal Plausibility Failure Sets when the RCM receives messages containing upper or lower data limits other than limits stored in memory. B00A0:68 Occupant Classification System: Event Information Sets when the RCM receives a message from the OCSM that indicates an OCS fault is present. Possible Causes OCSM DTCs OCSM RCM NOTE: Most faults are due to connector and/or wiring concerns. Carry out a thorough inspection and verification before proceeding with the pinpoint test. NOTE: Only disconnect or reconnect SRS components when instructed to do so within a pinpoint test step. Failure to follow this instruction may result in incorrect diagnosis of the SRS . PINPOINT TEST AG: STABILITY CONTROL SENSOR EVENT INFORMATION FAULTS (C006X:68) Introduction Normal Operation and Fault Conditions The RCM provides the stability/traction control system with acceleration sensor data over the HS-CAN 2. In addition to transmitting the data, the RCM monitors this data internally to make sure that the data is within an expected range. If the data is outside of the expected range and a fault is detected, the RCM stores DTC C0061:68, C0062:68, C0063:68, C0064:68, and/or C0065:68 in memory. However, the RCM does not request that the IPC illuminate the airbag warning indicator when these faults are present. DTC Fault Trigger Conditions DTC Description Fault Trigger Condition C0061:68 Lateral Acceleration Sensor: Event Information A fault is indicated when the lateral acceleration sensor is transmitting data that is outside of the range expected by the RCM. C0062:68 Longitudinal Acceleration Sensor: Event Information A fault is indicated when the longitudinal acceleration sensor is transmitting data that is outside of the range expected by the RCM. C0063:68 Yaw Rate Sensor: Event Information A fault is indicated when the yaw rate sensor is transmitting data that is outside of the range expected by the RCM. C0064:68 Roll Rate Sensor: Event Information A fault is indicated when the roll rate sensor is transmitting data that is outside of the range expected by the RCM. C0065:68 Vertical Acceleration Sensor: Event Information A fault is indicated when the vertical acceleration sensor is transmitting data that is outside of the range expected by the RCM. C006A:68 Multi-axis Acceleration Sensor: Event Information A fault is indicated when the multi-axis acceleration sensor is transmitting data that is outside of the range expected by the RCM. Possible Causes Aggressive driving conditions or rough roads RCM mounting RCM WARNING: Incorrect repair techniques or actions can cause an accidental SRS deployment. Never compromise or depart from these instructions. Failure to precisely follow all instructions could result in serious personal injury from an accidental deployment. NOTE: Most faults are due to connector and/or wiring concerns. Carry out a thorough inspection and verification before proceeding with the pinpoint test. NOTE: Only disconnect or reconnect SRS components when instructed to do so within a pinpoint test step. Failure to follow this instruction may result in incorrect diagnosis of the SRS . PINPOINT TEST AR: RCM IDENTIFIED AS CAUSE OF FAULT Introduction Normal Operation and Fault Conditions The RCM monitors various inputs and communicates on the CAN . If the values received are out of range or not what should be expected, the RCM sets a DTC . DTC Fault Trigger Conditions DTC Description Fault Trigger Condition B0080:11 Driver Seat Belt Load Limiter Deployment Control: Circuit Short To Ground Sets when the RCM detects an incorrect configuration. B0080:12 Driver Seat Belt Load Limiter Deployment Control: Circuit Short To Battery Sets when the RCM detects an incorrect configuration. B0080:13 Driver Seat Belt Load Limiter Deployment Control: Circuit Open Sets when the RCM detects an incorrect configuration. B0080:1A Driver Seat Belt Load Limiter Deployment Control: Circuit Resistance Below Threshold Sets when the RCM detects an incorrect configuration. B0080:2B Driver Seat Belt Load Limiter Deployment Control: Signal Cross Coupled Sets when the RCM detects an incorrect configuration. B1193:00 Crash Event Storage Full and Locked: No Sub Type Information Sets when the RCM has detected a crash event. B142D:00 Pyrotechnic End of Life Activation Performed: No Sub Type Information Sets when the RCM has experienced a pyrotechnic activation event. U2101:00 Control Module Configuration Incompatible: No Sub Type Information Sets when the RCM detects an incorrect configuration. U2200:00 Control Module Configuration Memory Corrupt: No Sub Type Information Sets when the RCM detects an incorrect configuration. U3000:04 Control Module: System Internal Failure Sets when the RCM detects an internal failure. U3000:46 Control Module: Calibration/Parameter Memory Failure Sets when the RCM detects an internal failure. U3000:49 Control Module: Internal Electronic Failure Sets when the RCM detects an internal failure. Possible Causes Intermittent concern RCM

-

GENERAL SERVICE BULLETIN Rear-View Mirror Concern Analysis 24-7133 16 December 2024 This bulletin supersedes 23-7173. Reason for update: add the interior review view mirror update Summary This article is designed to provide examples of interior and exterior rear-view mirror conditions/damage to assist in determining if the condition is warrantable or non-warrantable. Refer to the latest version of the Warranty and Policy Manual online for the latest rear-view mirror warranty coverage information. Use this article to assist in determining warrantable interior and exterior rear-view mirror concerns. Service Information Vehicles with power folding rear-view mirrors may exhibit concerns such as inoperative, folding with clicking sounds, vibrating/shaking in wind/while driving, or does not lock firmly in drive position. This may occur when the exterior rear-view mirrors are manually folded in such as going through a car wash, being bumped in transportation or a parking lot, or only one mirror is folded in. This may be attributed to the power folding mirror being out of synchronization or damage to the mirror mount. Perform the mirror synchronization procedure prior to completing any additional diagnostics. The synchronization procedure may need to be performed more than once to receive the loud popping sound, which is an indication the synchronization procedure has completed. Refer to WSM Section 501-09 Rear View Mirrors – General Procedures – Power Mirrors Synchronization. If the synchronization procedure does not correct the concern, continue with cleaning and inspection before performing additional diagnostics. Diagnostic test results and resynchronization information must be documented if a warrantable defect is found. Concerns that are corrected by the power mirror synchronization should not be submitted under warranty. Loose manual folding exterior rear-view mirrors are most commonly the result of damage to the assembly/mount. Closely inspect the exterior rear-view mirror after cleaning to review for witness marks/impact damage. Loose interior rear-view mirror mounts are most commonly the result of not being seated or the mount/attachment being damaged. Reseating the mirror per the WSM, Section 501-09 Rear View Mirrors may correct this concern. If the windshield has been replaced, damage to the mount can occur from improper removal/installation. Pen test A pen test should be used to determine mirror glass impact damage. Slowly run the tip of a ball point pen inside the crack throughout its entire length. If an impact is present, the pen helps to feel an impression. Cleaning procedure Clean the entire mirror assembly and glass to assist in verification of the customer concern and/or impact damage using water, a cloth, and car wash soap as needed. Do not clean any mirror glass or housing with an ice scraper, razor blade, abrasive pad, harsh chemicals or petroleum based cleaning products, as these may damage the mirror glass and/or housing. Use steel wool no greater than 0000 grade on the on the mirror glass only, in a circular motion then rinse/wipe with water or a non-abrasive glass cleaner. Examples Of Non-warrantable And Warrantable Conditions A rear-view mirror assembly can be damaged from abuse or impact and show little or no witness marks on housing. Shiny or flat spots on the housing indicate abuse or impact. Typical non-warrantable damage from abuse or impact Exterior mirror: • Mirror glass missing • Glass with scratches or cracks • Glass loose due to broken pivot or missing jackscrews • Scrapes on housing resulting from impact or abuse • Attachments loose due to impact • Broken mirror motor plate • Glass reattached (glued) after impact • Broken pivot neck/housing Interior mirror: • Interior mirror glass cracked • Broken windshield at mirror mount • Interior mirror detached pivot Typical warrantable conditions • Glass discoloration • Distorted mirror glass reflection • Electrical failure of motors and switches • Wiring harness shorted • Single line glass crack on heated mirror (verified with pen test) • Single line glass stress crack (verified with pen test) NOTE: All mirror components should be serviced at the lowest level available per the Warranty and Policy Manual. Over-repairs when lower-level components are available are subject to review and warranty adjustment. Dirty Mirror Housing (Non-warrantable) (Figure 1) Dirty mirror housings cannot be properly inspected for outside source influence. Mirrors returned without proper cleaning are subject to warranty review and adjustment. Figure 1 Scrapes, Impact, Broken Housing, Loose Attachment (Non-warrantable) (Figure 2) Figure 2 Power Folding Mirror Detent Pin Damage (Non-warrantable) (Figures 3-5) Power-fold trailer tow mirrors are designed to operate the mirror between home to folded position. They are also designed to manually fold forward beyond home position. If the mirror is forcefully pushed beyond the forward fold position, the detent pin in the mirror is damaged and will not stop at home position using the power-fold button. To test this, push the power-fold button. If the mirror unfolds forward past home position (using the power fold button), it is not warrantable. Figure 3 Figure 4 Figure 5 Grain Removed From Plastic Mirror Housing (Non-warrantable) (Figure 6) Physical damage that is often accompanied by power-fold mirror detent pin damage. Figure 6 Glass Loose, Broken Motor (Non-warrantable) (Figures 7-8) Figure 7 Missing mirror glass/backing plate missing (non-warrantable) (Figure 😎 Figure 8 Melted Housing (Non-warrantable) (Figures 9-10) Indicates exposure to excessive heat or chemical contact. Figure 9 Figure 10 Discolored Housing (Non-warrantable) (Figure 11) Stains may have a liquid drip or spray pattern (shown) from contact with harsh liquids. Figure 11 Discolored Glass (Warrantable) (Figure 12) Figure 12 Distorted Mirror Glass Reflection (Warrantable) (Figure 13) Figure 13 Single Line Crack On Heated Mirror (Warrantable) (Figure 14) This crack will occur from thermal stress. Refer to the pen test at the beginning of this article to determine impact damage. Figure 14 Distorted Puddle Lamp Projected Image (Warrantable) (Figure 15) Figure 15 Portion Of Missing Glass (Warrantable) (Figure 16) Adhesive is still present on the mirror backing plate which is securely attached to the motor. Figure 16 Interior Mirror Glass Cracked (Non-warrantable) (Figure 17) Excessive force including improper removal/installation. Figure 17 Broken Windshield (Non-warrantable) (Figure 18) Excessive force including improper removal/installation. Figure 18 Interior Mirror Detached Pivot (Non-warrantable) (Figure 19) Excessive force will detach the press fit pivots. Figure 19 Blocked Light Sensor (Non-warrantable) (Figure 20) Obstruction will cause inoperative automatic high beam. Figure 20 Smudge Interior Mirror (Figure 21) Use steel wool no greater than 0000 grade on the on the mirror glass only, in a circular motion then rinse/wipe with water or a non-abrasive glass cleaner. Figure 21 © 2024 Ford Motor Company All rights reserved. NOTE: This information is not intended to replace or supersede any warranty, parts and service policy, workshop manual (WSM) procedures or technical training or wiring diagram information.

- 1 reply

-

- 3

-

-

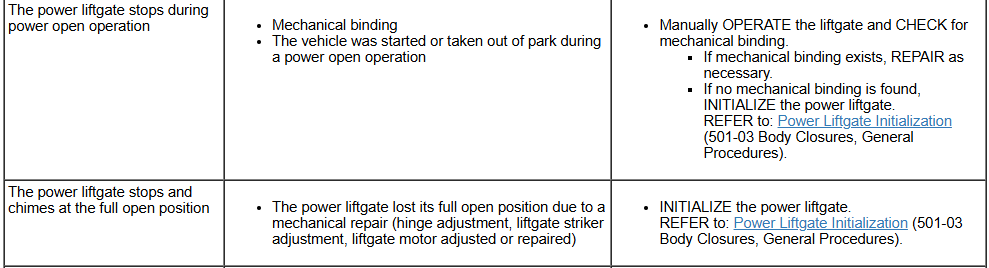

It's performing a scan of a single module -- or all modules -- for DTCs. Looking to the Workshop Manual's Power Liftgate diagnostic symptom chart... From Power Liftgate System Operation and Component Description... Power Open The power liftgate power open operation begins when: the RGTM detects the front power liftgate switch is activated. the RGTM detects the rear exterior liftgate release switch is activated. the RGTM receives a message from the BCM (indicating a request from a programmed RKE transmitter or a passive entry feature request). Once the RGTM receives an open request, the power liftgate opens by carrying out the following: The RGTM checks the gear selector lever position and vehicle speed status from the messages received. The RGTM supplies power to the unlatch motor, releasing the liftgate latch The RGTM monitors the liftgate ajar state (the liftgate latch pawl switch opens and both forkbolt switches close to indicate the latch has fully released). When the RGTM detects the power liftgate latch is fully unlatched, it supplies power to the drive motor, opening the power liftgate. While the power liftgate is opening, the RGTM monitors the liftgate motor position sensor for liftgate position and velocity. If an obstruction is detected, the RGTM stops the liftgate drive motor. When the power liftgate reaches the full open position, the RGTM removes the power from the drive motor. If any of the power liftgate switches is activated, a request for the hands-free feature is detected or a double press of the button on a RKE transmitter occurs during a power open, the liftgate stops and holds its position. Power Close The power liftgate power close operation begins when: the RGTM detects the front power liftgate switch is pressed. the RGTM detects the rear interior power liftgate switch is pressed. the RGTM receives a message from the BCM (indicating a double button press from a RKE transmitter or a hands-free request). Once the close request is received, the power liftgate closes by carrying out the following: The RGTM checks the gear selector lever position and vehicle speed status from the messages received. The RGTM starts an audible chime via the audio system. The RGTM supplies power to the drive motor. While the power liftgate is closing, the RGTM monitors the power liftgate motor position sensor (for liftgate position and velocity) and the anti-pinch switches. If an obstruction is detected, the power liftgate stops and reverses. The RGTM monitors the liftgate ajar state. When the RGTM detects the latch has engaged the striker (switches in the latch changing state), power is supplied to the cinching motor to pull the liftgate into the primary latch position and power is removed from the liftgate drive motor. When the RGTM detects the primary latch position has been reached (liftgate is fully closed), the RGTM reverses the direction of the cinching motor until the sector gear switch indicates a start position. If any of the power liftgate switches is activated, a request for the hands-free feature is detected or the button on the RKE transmitter is double pressed during a power close, the liftgate stops and holds its position. NOTE: The power liftgate may not operate correctly under the following conditions: Excessive weight (such as snow or ice) is present on the liftgate. A low voltage or drained battery. A disconnected battery. Repairs/adjustments have been made to the power liftgate strut, the power liftgate motor, the liftgate striker or the liftgate hinges. If any of these conditions have occurred, the power liftgate must be re-initialized. Refer to: Power Liftgate Initialization (501-03 Body Closures, General Procedures). Power Liftgate Open Height Programming The power liftgate open height can be programmed to open to a height other than the full open position. To program the power liftgate open height: Open the liftgate. Manually move the liftgate to the desired height. Press and hold the rear power liftgate close switch until a chime is heard, indicating that the new power liftgate maximum open height is successfully programmed. The programmed power liftgate height is retained when the battery is disconnected. Link to this FordParts webpage Good luck!

-Illustration-2021EdgeWorkshopManual.thumb.jpg.4b22832496db8b28eac4c659fae38a96.jpg)

-ConnectorC2129Location-2021Edge.jpg.afca1d8708ed061b2cc44d9e3895ba77.jpg)

Depowering-GeneralProcedures-2018EdgeWorkshopManual.thumb.jpg.a88cf6661fc06b9cf96b7543efde2681.jpg)

Repowering-GeneralProcedures-2018EdgeWorkshopManual.thumb.jpg.b60bd7d8858304d84fd413e40d64e3be.jpg)