Haz

Edge Member-

Posts

1,568 -

Joined

-

Last visited

-

Days Won

435

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

-

2011 Edge Cooling Fans not running

Haz replied to atrdriver's topic in Interior, A.C., Heat, Interior Trim

Multi-model diagnostic procedure and Edge-specific supporting documents to address your Edge's cooling fan issue... Document download links> Pinpoint Test KN - Variable Speed Electric Cooling Fan - Powertrain Control-Emissions Diagnosis Manual.pdf COOLING FAN MODULE - Without Trailer Tow - Wiring Diagram - 2011 Edge Workshop Manual.pdf COOLING FAN MODULE - With Trailer Tow - Wiring Diagram - 2011 Edge Workshop Manual.pdf Battery Junction Box (BJB) - Illustration - 2011 Edge.pdf Battery Junction Box (BJB) - Fuse & Relay Listing - 2011 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Details - 2011 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Location - 2011 Edge.pdf COOLING FAN MODULE - Connector C1554 Details - 2011 Edge.pdf COOLING FAN MODULE - Connector C1554 Location - 2011 Edge Workshop Manual.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Location - 2011 Edge.pdf Air Cleaner - Removal and Installation - 2011 Edge Workshop Manual.pdf Intake Air System Components - Exploded View Enhanced Image - 2011 Edge-MKX Workshop Manual.pdf Intake Air System Components - Exploded View - 2011 Edge-MKX Workshop Manual.pdf Cooling Fan and Shroud - Removal and Installation - 2011 Edge Workshop Manual.pdf Cooling Fan and Shroud - R&I Enhanced Image - 2011 Edge Workshop Manual.pdf Cooling Fan and Shroud - R&I Enhanced Connectors Illustration - 2011 Edge Workshop Manual.pdf Good luck! -

Good luck!

-

Welcome to the Forum, Remis ! Diagnostic information from the 2015 Edge Workshop Manual... The Manual Liftgate Latch Release Is Inoperative Normal Operations and Fault Conditions Liftgate Latch Release (manual liftgate) The liftgate latch can be released using: the exterior liftgate release switch. a valid programmed passive key. The BCM sends a voltage signal to the exterior liftgate release switch. When the liftgate release switch is pressed, the voltage signal is routed to ground, indicating a request to release the liftgate latch. The BCM momentarily provides voltage to the liftgate latch to actuate the release motor. When using the liftgate release switch, the BCM releases the liftgate only when the doors have been electronically unlocked and the vehicle is in PARK. When using a programmed RKE transmitter, press the liftgate release button twice within 3 seconds to release the liftgate latch. The liftgate latch releases if the vehicle speed is 5 km/h (3.1 mph) or less. The liftgate latch can also be released using the passive entry feature. Refer to Liftgate Passive Entry in this section. Passive Entry (if equipped) NOTE: To perform an accurate diagnosis of a concern, make sure the vehicle has a fully charged 12V battery and is in good condition when performing any electrical pinpoint tests. When the vehicle’s 12-volt battery is below a set threshold, certain features can be limited or become inoperative and lead to misdiagnosis. NOTE: Some models are not equipped with the passive entry feature, but are equipped with push button start. The passive entry feature unlocks or locks the doors or opens the liftgate without having to use a mechanical key blade or the RKE transmitter feature. When the BCM detects a lock or unlock sensor is touched on an exterior door handle, or the exterior liftgate release button is pressed, it activates the low frequency antenna in the corresponding exterior door handle or inside the luggage compartment area. The low frequency antenna sends out a signal to activate the passive key. The passive key then responds by sending a high frequency signal back to the RTM . The RTM interprets the high frequency signal from the passive key and sends the information to the BCM . If the BCM detects a valid programmed passive key, the BCM unlocks the driver door, unlocks or locks all 4 doors, releases the liftgate latch (manual liftgate) or sends a command to the RGTM to power open the liftgate (power liftgate). The passive entry (Intelligent Access) feature is part of vehicle load shed strategy. BCM DTC Fault Trigger Conditions DTC Description Fault Trigger Conditions B1219:11 Interior Boot/Trunk Release Switch: Circuit Short To Ground Sets when the BCM detects a short to ground from the exterior liftgate release switch input circuit. B12EE:11 Liftgate/Tailgate/Trunk Release: Circuit Short To Ground Sets when the BCM detects a short to ground from the liftgate latch release output circuit. B12EE:15 Liftgate/Tailgate/Trunk Release: Circuit Short To Battery or Open Sets when the BCM detects an open from the liftgate latch release output circuit. If the liftgate latch release is inoperative, GO to Pinpoint Test N If the liftgate does not latch, DISCONNECT the liftgate latch electrical connector and CHECK the operation of the latch using a screwdriver. If the latch does not fully latch (2 clicks), INSTALL a new liftgate latch. If the latch fully latches (2 clicks), REFER to the Wiring Diagrams manual to identify the possible cause of the circuit short in the liftgate latch release circuit. Possible Causes Wiring, terminals or connectors Liftgate release switch Liftgate latch BCM Visual Inspection and Diagnostic Pre-checks Inspect the liftgate release switch for damage. PINPOINT TEST N: THE MANUAL LIFTGATE LATCH RELEASE IS INOPERATIVE NOTE: This pinpoint test does not diagnose liftgate release concerns for vehicles with the power liftgate feature. Refer to Section 501-03 for power liftgate diagnostics. N1 CHECK THE LIFTGATE RELEASE INPUT FOR A SHORT TO GROUND USING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Ignition ON. Using a diagnostic scan tool, view the BCM Parameter Identifications (PIDs). Using a diagnostic scan tool, view the BCM PID LFTGATE_R_SW. Does the PID indicate the liftgate release switch is continuously pressed? Yes GO to N2 No GO to N4 N2 CHECK THE LIFTGATE RELEASE SWITCH USING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Ignition OFF. Disconnect Liftgate Release Switch C4216. Ignition ON. Using a diagnostic scan tool, view the BCM PID LFTGATE_R_SW. Does the PID continue to indicate the switch is pressed? Yes GO to N3 No INSTALL a new liftgate release switch. REFER to: Liftgate Release Switch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). N3 CHECK THE LIFTGATE RELEASE SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND Ignition OFF. Disconnect BCM C2280D. Measure: Positive Lead Measurement / Action Negative Lead C4216 Pin 1 Ground Is the resistance greater than 10,000 ohms? Yes GO to N12 No REPAIR the circuit. N4 CHECK THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Using a diagnostic scan tool, view the BCM LFTGATE_R_SW PID while pressing the liftgate release switch. Does the PID indicate the switch is pressed? Yes GO to N8 No GO to N5 N5 BYPASS THE LIFTGATE RELEASE SWITCH WHILE MONITORING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Ignition OFF. Disconnect Liftgate Release Switch. Ignition ON. Connect: Lead 1 Measurement / Action Lead 2 C4216 Pin 1 C4216 Pin 2 Using a diagnostic scan tool, view the BCM LFTGATE_R_SW PID . Does the PID indicate the switch is pressed? Yes REMOVE the fused jumper wire. INSTALL a new liftgate release switch. REFER to: Liftgate Release Switch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). No REMOVE the fused jumper wire. GO to N6 N6 CHECK THE LIFTGATE RELEASE SWITCH GROUND CIRCUIT FOR AN OPEN WHILE MONITORING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Connect: Lead 1 Measurement / Action Lead 2 C4216 Pin 1 Ground Using a diagnostic scan tool, view the BCM LFTGATE_R_SW PID . Does the PID indicate the switch is pressed? Yes REMOVE the fused jumper wire. REPAIR the circuit. No REMOVE the fused jumper wire. GO to N7 N7 CHECK THE LIFTGATE RELEASE SWITCH INPUT CIRCUIT FOR AN OPEN Ignition OFF. Disconnect BCM C2280D. Measure: Positive Lead Measurement / Action Negative Lead C4216 Pin 1 C2280D Pin 1 Is the resistance less than 3 ohms? Yes GO to N12 No REPAIR the circuit. N8 CHECK FOR VOLTAGE TO THE LIFTGATE LATCH RELEASE MOTOR NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector. Ignition OFF. Disconnect Liftgate Latch C479. Ignition ON. Using a diagnostic scan tool, carry out the BCM self-test. Connect: Positive Lead Measurement / Action Negative Lead C479 Pin 2 Ground Unlock the doors using a door lock control switch. NOTE: The BCM only supplies voltage to the actuator momentarily. It is important to monitor the test lamp while pressing the liftgate release switch. While pressing the liftgate release switch, monitor the test lamp. Does the test lamp momentarily illuminate? Yes GO to N9 No GO to N10 N9 CHECK THE LIFTGATE LATCH RELEASE MOTOR GROUND CIRCUIT FOR AN OPEN NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector. Connect: Positive Lead Measurement / Action Negative Lead C479 Pin 2 C479 Pin 5 NOTE: The BCM only supplies voltage to the actuator momentarily. It is important to monitor the test lamp while pressing the liftgate release switch. While pressing the liftgate release switch, monitor the test lamp. Does the test lamp momentarily illuminate? Yes INSTALL a new liftgate latch. REFER to: Liftgate Latch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). No REPAIR the circuit. N10 CHECK THE LIFTGATE LATCH RELEASE MOTOR VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO GROUND Ignition OFF. Disconnect BCM C2280F. Measure: Positive Lead Measurement / Action Negative Lead C479 Pin 2 Ground Is the resistance greater than 10,000 ohms? Yes GO to N11 No REPAIR the circuit. N11 CHECK THE LIFTGATE LATCH RELEASE MOTOR VOLTAGE SUPPLY CIRCUIT FOR AN OPEN Measure: Positive Lead Measurement / Action Negative Lead C479 Pin 2 C2280F Pin 31 Is the resistance less than 3 ohms? Yes GO to N12 No REPAIR the circuit. N12 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION Disconnect and inspect all the BCM connectors. Repair: corrosion (install new connectors or terminals - clean module pins) damaged or bent pins - install new terminals pins pushed-out pins - install new pins as necessary Reconnect the BCM connectors and make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, VIN required to access Guided Routine (BCM) No The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause of any connector or pin issues. Document download links> Liftgate Latch Manual Release - General Procedures - 2015 Edge Workshop Manual.pdf Liftgate Latch - Removal and Installation - 2015 Edge Workshop Manual.pdf LIFTGATE-LUGGAGE COMPARTMENT LID LATCH - Connector C479 Details - 2015 Edge.pdf LIFTGATE-LUGGAGE COMPARTMENT LID LATCH - Connector C479 Location - 2015 Edge.pdf Liftgate Release Switch - Removal and Installation - 2015 Edge Workshop Manual.pdf LIFTGATE RELEASE SWITCH - Connector C4216 Details - 2015 Edge.pdf LIFTGATE RELEASE SWITCH - Connector C4216 Location - 2015 Edge.pdf Liftgate Trim Panel - Removal and Installation - 2015 Edge Workshop Manual.pdf Body Control Module (BCM) - Connectors C2280D & C2280F Attachment Locations on BCM - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280D Details - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280D Location - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280F Details - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280F Location - 2015 Edge.pdf Beyond this Pinpoint Test N diagnostic procedure, I find no Technical Service Bulletin (TSB) addressing the liftgate latching issue you describe. Good luck!

-

P1450 code Purge Valve fixed but code comes back again one month later?

Haz replied to fairlaniac's topic in 2.0L EcoBoost

From the 2017 Ford Powertrain Control/Emissions Diagnosis Manual, a multi-model/multi-engine diagnostic reference... Document download link> PINPOINT TEST HX - EVAPORATIVE EMISSION (EVAP) SYSTEM AND MONITOR.pdf If you progress toward undertaking the many circuit tests in the Pinpoint Test HX diagnostic procedure, I can provide Edge-specific connector details and location illustrations, and wiring diagrams. Good luck! -

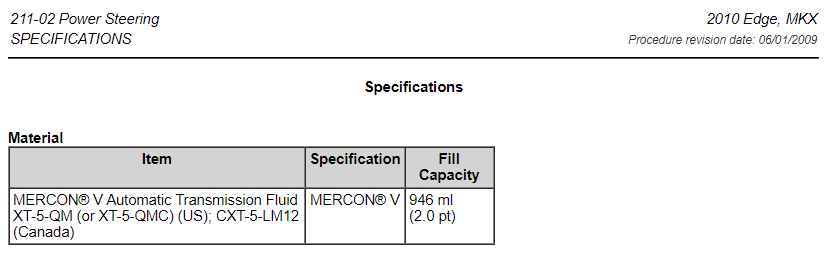

Welcome to the Forum, CEdge2010 ! From the 2010 Edge Workshop Manual... Power Steering Fluid Leak Test NOTE: This test should only be carried out if a leak in the system has not been detected during a thorough visual inspection. Refer to Inspection and Verification in this section. Remove the power steering pump reservoir cap and check the power steering fluid level. If necessary, add the specified power steering fluid. Tightly install the Power Steering Evacuation Cap onto the reservoir and connect the Vacuum Pump Kit to the Evacuation Cap. Using the Vacuum Pump Kit, apply 68-85 kPa (20-25 in-Hg) of vacuum to the power steering system. Observe the vacuum gauge for 30 seconds. If the vacuum gauge reading drops more than 3 kPa (0.88 in-Hg), a leak is present. Remove the Vacuum Pump Kit. Start the engine and insert the Dial Thermometer into the Evacuation Cap. NOTICE: Do not hold the steering wheel at the stops for an extended amount of time. Damage to the power steering pump may occur. With the engine at idle, raise the power steering fluid temperature to 74-80°C (165-176°F) by rotating the steering wheel fully to the left and right several times. Stop the engine and visually inspect the system for leaks. If a leak is evident, repair as necessary. If a leak is not evident, add the specified UV fluorescent tracer dye to the power steering fluid. Use 14.78 ml (1/2 oz) of dye solution for every 1.89L (2 qt) of power steering fluid. Start the engine. NOTICE: Do not hold the steering wheel at the stops for an extended amount of time. Damage to the power steering pump may occur. With the engine at idle, raise the power steering fluid temperature to 74-80°C (165-176°F) by rotating the steering wheel fully to the left and right several times. Stop the engine and inspect the system for traces of UV dye using the 100W/12 Volt DC UV Lamp. Repair as necessary. Document download links> Power Steering System Flushing - General Procedures - 2010 Edge Workshop Manual.pdf Power Steering System Purging - General Procedures - 2010 Edge Workshop Manual.pdf Power Steering System Filling - General Procedures - 2010 Edge Workshop Manual.pdf Good luck!

-

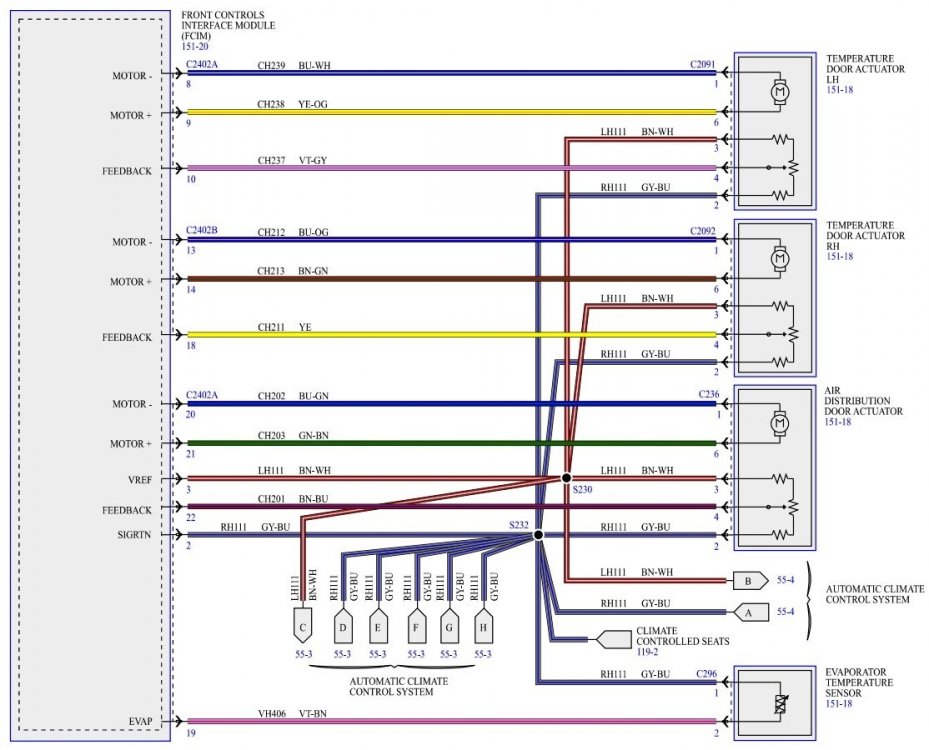

Blend,Mode and Recirculation

Haz replied to 2015Edge2015's topic in Interior, A.C., Heat, Interior Trim

From the 2015 Edge Workshop Manual... Climate Control System - Dual Automatic Temperature Control (DATC) - Component Location Air Handling There are 4 door actuators that control the air flow into the passenger compartment: Air distribution Air inlet Driver side temperature Passenger side temperature All of the door actuators contain a reversible electric motor and a potentiometer. The potentiometer circuit consists of a 5-volt reference signal connected to one end of a variable resistor, and a signal ground connected to the other. A signal circuit is connected to a contact wiper, which is driven along the variable resistor by the actuator shaft. The signal to the FCIM from the contact wiper indicates the position of the actuator door. The FCIM powers the actuator motors to move the doors to the desired positions. The desired door positions are calculated by the FCIM based on the set temperature, in-vehicle temperature, ambient air temperature and sunload. When an airflow mode, desired driver or passenger temperature, fresh air, or recirculation mode is selected, the FCIM moves the actuator motor in the desired direction. The FCIM sends a PWM signal to the blower motor speed control to regulate the blower speed as necessary. The blower motor speed control provides variable ground feed for the blower motor based on the input from the FCIM . A delay function provides a gradual increase or decrease in blower motor speed under all conditions. AUTO When AUTO is selected: the HVAC system operates in a manner to achieve and maintain the temperature set by the operator. the driver and passenger side temperature doors are automatically controlled by the FCIM based on the temperature setting. the A/C compressor is automatically controlled by the PCM from information sent by the FCIM , based on the temperature setting. The A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the blower motor speed is automatically controlled through the blower motor speed control that receives a PWM signal from the FCIM based on the temperature setting, but can be manually overridden. the FCIM controls the air inlet door to recirculate, partially recirculate or open to the fresh air position depending on the in-car temperature and humidity sensor inputs. OFF When OFF is selected: the air inlet door closes, preventing outside air and allowing only recirculated air. the blower motor is off. MAX A/C When MAX A/C is selected: the air inlet door closes, preventing outside air and allowing only recirculated air. the recirculated air indicator is illuminated (recirculated air forced on). the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. the temperature doors move to the full cool position. Air temperature can be manually overridden. the A/C button is illuminated. the A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the blower motor is commanded to the highest speed. The blower motor speed is adjustable. PANEL When PANEL mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. PANEL/FLOOR When PANEL/FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct and the instrument panel registers. A small amount of airflow from the side window demisters and defrost duct is present. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. FLOOR When FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct. A small amount of airflow from the defroster duct and side window demisters is present. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. FLOOR/DEFROST When FLOOR/DEFROST mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct, the defroster duct and the side window demisters. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. MAX DEFROST When MAX DEFROST mode is selected: the recirculated air request button is disabled. The air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the defroster duct and side window demisters. A small amount of airflow from the floor duct is present. the A/C is turned on in defrost mode. The A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the temperature is set to the highest setting and is not adjustable. the fan is set to the highest speed and is not adjustable. MAX DEFROST can be exited by pressing the AUTO button. Climate Control System - Dual Automatic Temperature Control (DATC) - Front Controls Interface Module (FCIM) to Air Flow Door Actuators - Wiring Diagram Climate Control System - Electronic Manual Temperature Control (EMTC) - Component Location Air Handling There are 3 door actuators that control the air flow into the passenger compartment: Air distribution Air inlet Temperature All of the door actuators contain a reversible electric motor and a potentiometer. The potentiometer circuit consists of a 5-volt reference signal connected to one end of a variable resistor, and a signal ground connected to the other. A signal circuit is connected to a contact wiper, which is driven along the variable resistor by the actuator shaft. The signal to the FCIM from the contact wiper indicates the position of the actuator door. The FCIM powers the actuator motors to move the doors to the desired positions. The desired door positions are calculated by the FCIM based on the set temperature, in-vehicle temperature, ambient air temperature and sunload. When an airflow mode, desired temperature, fresh air, or recirculation mode is selected, the FCIM moves the actuator motor in the desired direction. The FCIM sends a PWM signal to the blower motor speed control to regulate the blower speed as necessary. The blower motor speed control provides variable ground feed for the blower motor based on the input from the FCIM . A delay function provides a gradual increase or decrease in blower motor speed under all conditions. OFF When OFF is selected: the air inlet door closes, preventing outside air and allowing only recirculated air. the blower motor is off. MAX A/C When MAX A/C is selected: the air inlet door closes allowing only recirculated air. the recirculated air indicator is illuminated (recirculated air forced on). the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. the temperature door moves to the full cool position. Air temperature can be manually overridden. the A/C button is illuminated. the A/C compressor operates if the outside temperature is above approximately 0°C (32°F). the blower motor is commanded to the highest speed. The blower motor speed is adjustable. PANEL When PANEL mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. PANEL/FLOOR When PANEL/FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct and the instrument panel registers. A small amount of airflow from the side window demisters and defrost duct is present. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. FLOOR When FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct. A small amount of airflow from the defroster duct and side window demisters is present. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. FLOOR/DEFROST When FLOOR/DEFROST mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct, the defroster duct and the side window demisters. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. MAX DEFROST When MAX DEFROST mode is selected: the recirculated air request button is disabled. The air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the defroster duct and side window demisters. A small amount of airflow from the floor duct is present. the A/C is turned on in defrost mode. The A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the temperature is set to the highest setting and is not adjustable. the fan is set to the highest speed and is not adjustable. MAX DEFROST can be exited by pressing the AUTO button. Climate Control System - Electronic Manual Temperature Control (EMTC) - Front Controls Interface Module (FCIM) to Air Flow Door Actuators - Wiring Diagram Document download links> Air Distribution Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf Gateway Module A (GWM) - Removal and Installation - 2015 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Depowering - General Procedures - 2015 Edge Workshop Manual.pdf Driver Knee Airbag - Removal and Installation - 2015 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Repowering - General Procedures - 2015 Edge Workshop Manual.pdf Air Inlet Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf (Requires extensive disassembly of Instrument Panel and Floor Console not described in this document) Driver Side Temperature Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf Brake Pedal and Bracket - Removal and Installation - 2015 Edge Workshop Manual.pdf Stoplamp Switch - Removal and Installation - 2015 Edge Workshop Manual.pdf Accelerator Pedal - Removal and Installation - 2015 Edge Workshop Manual.pdf Passenger Side Temperature Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf Temperature Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf TEMPERATURE DOOR ACTUATOR RH - Connector C2092 Details - 2015 Edge.pdf FRONT CONTROLS INTERFACE MODULE (FCIM) - Connector C2402A Details - 2015 Edge.pdf FRONT CONTROLS INTERFACE MODULE (FCIM) - Connector C2402B Details - 2015 Edge.pdf Front Controls Interface Module (FCIM) - Removal and Installation - 2015 Edge Workshop Manual.pdf From Climate Control System - Dual Automatic Temperature Control (DATC) - Diagnosis and Testing - 2015 Edge Workshop Manual... FCIM - DATC DTC CHART B1082:13 Right Temperature Damper Motor: Open Circuit This DTC sets when the module senses no voltage on the actuator motor circuit when ground is applied to drive the motor, indicating a open circuit. The motor can not move. The Temperature Control Is Inoperative Or Does Not Operate Correctly - Passenger Side Normal Operation and Fault Conditions - Temperature Door Actuator - Passenger side During an actuator calibration cycle, the module drives the temperature door until the door reaches both internal stops in the HVAC case. If the temperature door is temporarily obstructed or binding during a calibration cycle, the module may interpret this as the actual end of travel for the door. When this condition occurs and the module commands the actuator to its end of travel, the airflow may not be the expected temperature. Possible Sources Wiring, terminals or connectors Passenger side temperature door actuator FCIM PINPOINT TEST J: THE TEMPERATURE CONTROL IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY - PASSENGER SIDE NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. J1 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TO VOLTAGE Ignition OFF. Disconnect FCIM C2402A. Disconnect FCIM C2402B. Disconnect Passenger side temperature door actuator C2092. Ignition ON. Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 1 Ground C2092 Pin 2 Ground C2092 Pin 3 Ground C2092 Pin 4 Ground C2092 Pin 6 Ground Is any voltage present? Yes REPAIR the circuit. No GO to J2 J2 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TO GROUND Ignition OFF. Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 1 Ground C2092 Pin 2 Ground C2092 Pin 3 Ground C2092 Pin 4 Ground C2092 Pin 6 Ground Are the resistances greater than 10,000 ohms? Yes GO to J3 No REPAIR the circuit. J3 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR AN OPEN Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 2 C2402A Pin 2 C2092 Pin 3 C2402A Pin 3 Positive Lead Measurement / Action Negative Lead C2092 Pin 1 C2402B Pin 13 C2092 Pin 4 C2402B Pin 18 C2092 Pin 6 C2402B Pin 14 Are the resistances less than 3 ohms? Yes GO to J4 No REPAIR the circuit. J4 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TOGETHER Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 1 C2092 Pin 2 C2092 Pin 1 C2092 Pin 3 C2092 Pin 1 C2092 Pin 4 C2092 Pin 1 C2092 Pin 6 C2092 Pin 2 C2092 Pin 3 C2092 Pin 2 C2092 Pin 4 C2092 Pin 2 C2092 Pin 6 C2092 Pin 3 C2092 Pin 4 C2092 Pin 3 C2092 Pin 6 C2092 Pin 4 C2092 Pin 6 Are the resistances greater than 10,000 ohms? Yes INSTALL a new passenger side temperature door actuator. REFER to: Passenger Side Temperature Door Actuator (412-00 Climate Control System - General Information, Removal and Installation). TEST the system for normal operation. If the concern is still present, GO to J5 No REPAIR the circuit. J5 CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE) OPERATION Ignition OFF. Disconnect and inspect all FCIM connectors. Repair: corrosion (install new connector or terminals – clean module pins) damaged or bent pins – install new terminals/pins pushed-out pins – install new pins as necessary Connect all FCIM connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, VIN required to access Guided Routine (FCIM) No The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS the root cause of any connector or pin issues. Good luck! -

Installation of a seat in EDGE SEL from TITANIUM

Haz replied to Yurez's topic in Accessories & Modifications

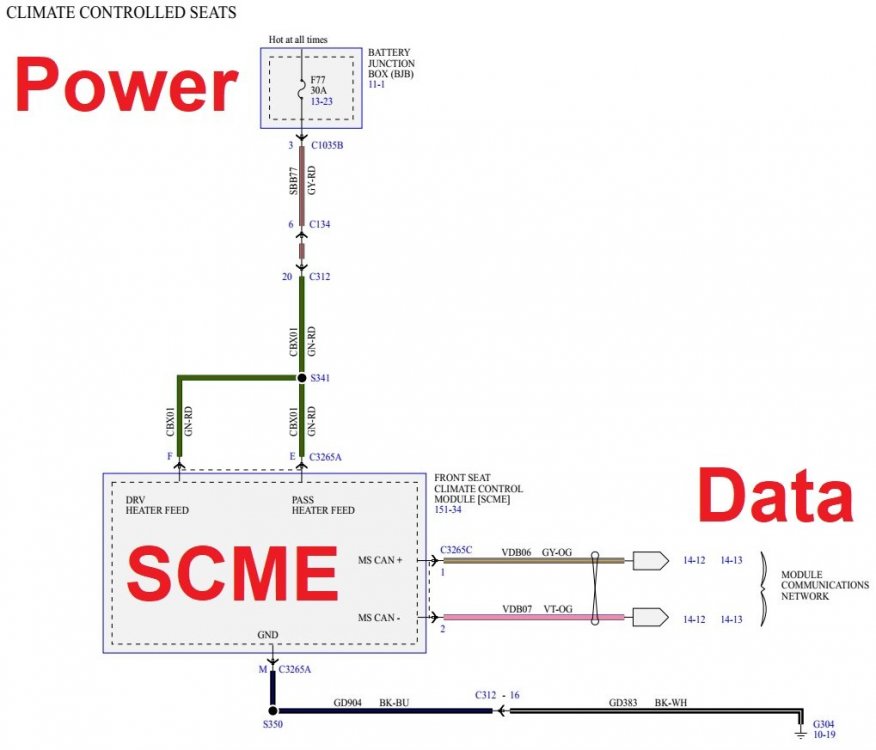

To accomplish your goal of installing the seats and making them fully functional: Buy an Edge Wiring Book in your native language. English language wiring diagrams and connector circuit details are obviously not working... From the document collection you received... Climate Controlled Seats - Wiring Diagram 1 - 2018 Edge.pdf, with Labels added Good luck! -

Installation of a seat in EDGE SEL from TITANIUM

Haz replied to Yurez's topic in Accessories & Modifications

Per enigma-2's comment on SRS Airbag System precautions... Document download links> Supplemental Restraint System (SRS) Depowering - General Procedures - 2015 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Repowering - General Procedures - 2015 Edge Workshop Manual.pdf Good luck! -

Installation of a seat in EDGE SEL from TITANIUM

Haz replied to Yurez's topic in Accessories & Modifications

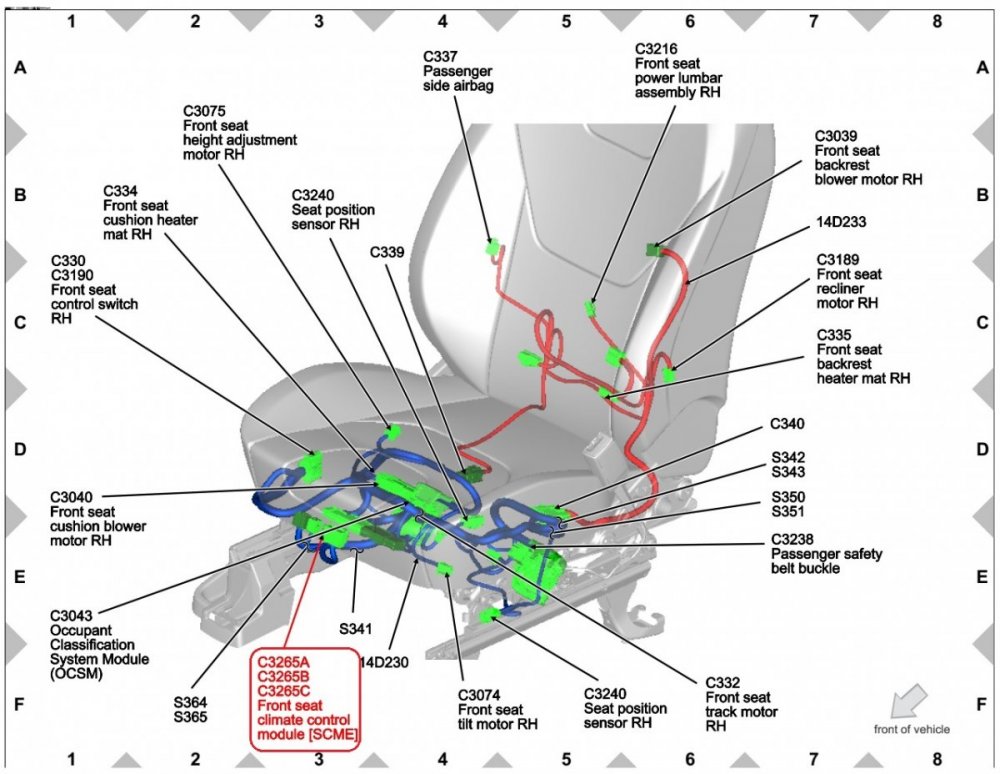

Always hopeful that visualizations are better than a thousand Google-translated words... Driver Seat Module (DSM) - Beneath Driver Seat Front Seat Climate Control Module (SCME) - Beneath Passenger Seat Documents relating to seat-to-seat "adapter cable", as you describe it... Document download links> Front Driver Seat - Connector C311 Details - 2018 Edge.pdf Front Driver Seat - Connector C311 Seat View Location - 2018 Edge.pdf Front Driver Seat - Connector C311 Harness View Location - 2018 Edge.pdf Front Passenger Seat - Connector C312 Details - 2018 Edge.pdf Front Passenger Seat - Connector C312 Location - 2018 Edge.pdf While Titanium-owning Forum members may offer their own hands-on Climate Controlled Seating insights, I am moving on to research other Forum member questions. Once again, speaking directly with Parts & Service personnel at your local Ford dealer will eliminate your need for Google Translate. Good luck! -

Installation of a seat in EDGE SEL from TITANIUM

Haz replied to Yurez's topic in Accessories & Modifications

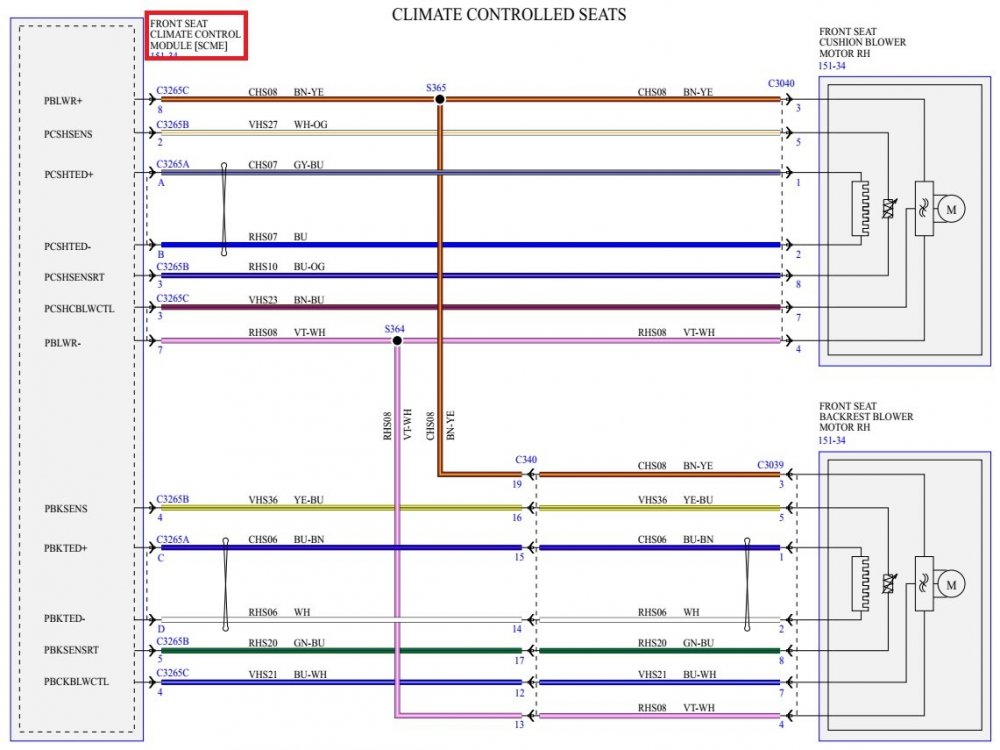

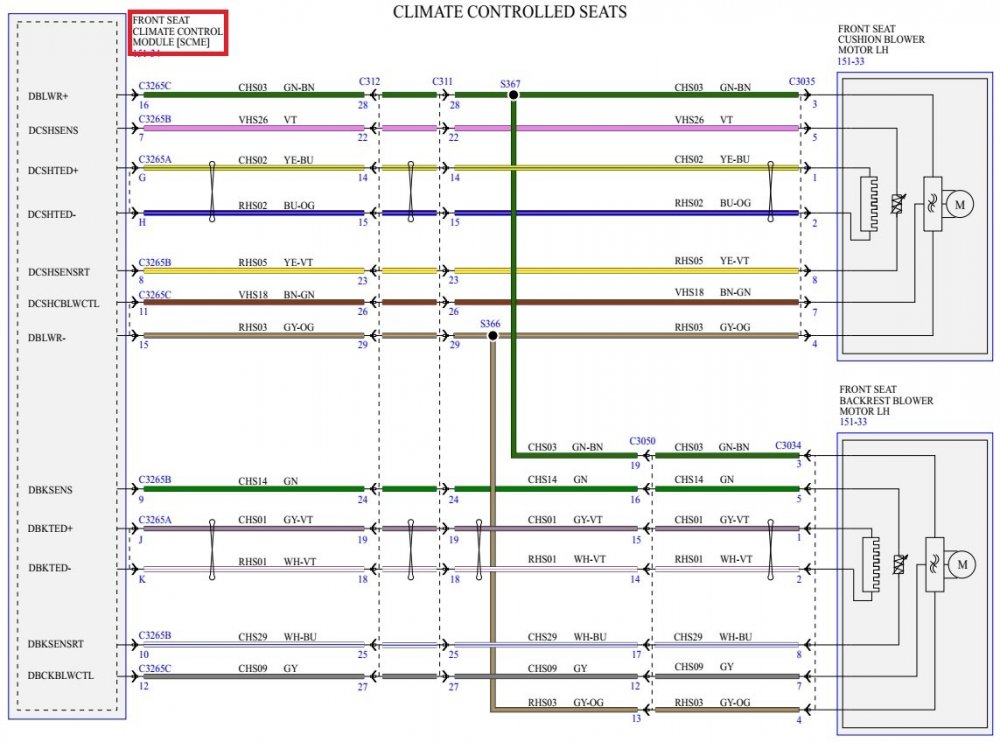

Information about the Front Seat Climate Control Module (SCME), shown in your above photo, was contained in the recently shared document collection, including: Climate Controlled Seats - Wiring Diagram 2 - 2018 Edge.pdf - showing SCME in relation to the Left Hand/Driver's seat... Climate Controlled Seats - Wiring Diagram 3 - 2018 Edge.pdf - showing SCME in relation to the Right Hand/Passenger's seat... FRONT SEAT CLIMATE CONTROL MODULE [SCME] -Connectors C3265A-C3265B-C3265C Location - 2018 Edge.pdf - showing all SCME connectors' relative location... The following documents provide Driver's Seat Module (DSM) connector details on SCME circuits affecting Driver's seat climate control components... Document download links> DRIVER SEAT MODULE (DSM) - Connector C341D Details - 2018 Edge.pdf DRIVER SEAT MODULE (DSM) - Connector C341E Details - 2018 Edge.pdf DRIVER SEAT MODULE (DSM) - Connectors C341D & C341E Location - 2018 Edge.pdf Good luck! -

The other mechanical switch risks would be the Start/Stop and Transmission Range (TR) switches, which should trigger DTCs. Additional, for the "Library"... Document download links> TIRE PRESSURE MONITOR (TPM) MODULE - Connector C4321 Details - 2011 Edge.pdf TIRE PRESSURE MONITOR (TPM) MODULE - Connector C4321 Location - 2011 Edge.pdf Good luck!

-

The immobilization effect of the Passive Anti-Theft System (PATS) occurs from the interaction of the Intelligent Access (IA) key fob and the Start push button with several electronic modules via related components and circuits in the vehicle. From the 2011 Edge Workshop Manual... (Placing your device cursor over underlined acronyms should result in a popup of the component's full name) Passive Anti-Theft System (PATS) With Intelligent Access (IA) The Passive Anti-Theft System (PATS) consists of the following components: Intelligent Access (IA) key Front passive start antenna (located on the bottom of the front of the floor console) Center passive start antenna (located in the rear of the floor console) Rear passive start antenna (located under the liftgate scuff trim panel, beneath the liftgate striker) Backup transceiver (located in the floor console, below the audio jacks) Tire Pressure Monitor (TPM) module Remote Function Actuator (RFA) module (located behind the glove compartment) Body Control Module (BCM) PCM Starting System - Principles of Operation With IA NOTE: This vehicle is equipped with Passive Anti-Theft System (PATS) that disables the engine if an unprogrammed PATS key is used or an invalid PCM ID is received. PATS is controlled by the Remote Function Actuator (RFA) module. If there is a PATS concern that cause the engine not to crank, the Instrument Panel Cluster (IPC) displays "STARTING SYSTEM FAULT" in the message center. Refer to Section 419-01B to diagnose a PATS concern. The Intelligent Access (IA) starting system is electronically controlled by the RFA module which acts as the PATS control function. The RFA receives the following inputs: Brake pedal applied input Start/stop switch is pressed Transmission in PARK or NEUTRAL signal from the Transmission Range (TR) sensor Run/start relay voltage. Correctly coded ignition key, from the RFA During a start event, the start/stop switch is pressed in combination with the brake pedal, the RFA module and BCM receives a request to start the engine. The RFA module communicates with the BCM . Once the BCM receives the command from the RFA module, it communicates with the PCM. Once the BCM initializes and communicates with the RFA module and the PCM, it checks the ID of each module and compares it with the module ID stored in its own memory. If the RFA module and PCM IDs match the IDs stored in the BCM , then PATS is enabled. The PCM recognizes the correct inputs and provides voltage and ground to energize the starter relay coil and close the starter relay contacts. The starter relay contacts close, providing voltage to the starter solenoid, allowing the starter motor to crank the engine. The PCM disengages the starter motor once an engine rpm threshold is reached, a set crank time is exceeded or the stop/start button is pressed indicating an engine shutdown. Remote Function Actuator (RFA) Module - Principles of Operation The Remote Function Actuator (RFA) module is only equipped when the vehicle has the Intelligent Access (IA) feature. On vehicles equipped with this option, the RFA controls mostly the IA and related entry/anti-theft systems (such as the power door locks and the liftgate release). The RFA module communicates on the Medium Speed Controller Area Network (MS-CAN) . The RFA module controls the following functions: Intelligent Access (IA) feature Keyless entry keypad illumination Liftgate release Passive Anti-Theft System (PATS) Power door locks Remote Keyless Entry (RKE) system The following collection of documents provide fuller detail on component interaction, wiring diagrams and electrical connector details & connector locations, and diagnosis & testing procedures that may equip you, if you choose to identify the root of the problem yourself, or at least, will enhance your awareness if you decide to turn the job over to your dealer's Service technicians. Document download links> Anti-Theft — With Intelligent Access (IA) - Diagnosis and Testing - 2011 Edge Workshop Manual.pdf Starting System - Diagnosis and Testing - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Diagnosis and Testing - 2011 Edge Workshop Manual.pdf Handles, Locks, Latches and Entry Systems — With Intelligent Access (IA) - Diagnosis and Testing - 2011 Edge Workshop Manual .pdf Tire Pressure Monitoring System (TPMS) - Diagnosis and Testing - 2011 Edge Workshop Manual.pdf Body Control Module (BCM) - Removal and Installation - 2011 Edge Workshop Manual.pdf Body Control Module (BCM) Fuse Protected-Circuits Legend - HIGHLIGHTED - Wiring Diagram - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Removal and Installation - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Enhanced Image - 2011 Edge Workshop Manual.pdf Powertrain Control Module (PCM) - Removal and Installation - 2011 Edge Workshop Manual.pdf Tire Pressure Monitor (TPM) Module - Removal and Installation - 2011 Edge Workshop Manual.pdf Passive Anti-Theft System - Wiring Diagram - Cell 112 , Page 02 - 2011 Edge Workshop Manual.pdf Passive Anti-Theft System - Wiring Diagram - Cell 112 , Page 03 - 2011 Edge Workshop Manual.pdf Power Distribution-BCM - Wiring Diagram - Cell 013, Page 12 - 2011 Edge Workshop Manual.pdf Remote Keyless Entry and Alarm - Wiring Diagram - Cell 117, Page 06 - 2011 Edge Workshop Manual.pdf Remote Keyless Entry and Alarm - Wiring Diagram - Cell 117, Page 07 - 2011 Edge Workshop Manual.pdf Remote Keyless Entry and Alarm - Wiring Diagram - Cell 117, Page 08 - 2011 Edge Workshop Manual.pdf Remote Keyless Entry and Alarm - Wiring Diagram - Cell 117, Page 09 - 2011 Edge Workshop Manual.pdf Remote Keyless Entry and Alarm - Wiring Diagram - Cell 117, Page 10 - 2011 Edge Workshop Manual.pdf Starting System -Wiring Diagram - Cell 020, Page 02 - 2011 Edge Workshop Manual.pdf Tire Pressure Monitor System - Wiring Diagram - Cell 118, Page 01 - 2011 Edge Workshop Manual.pdf Backup Transceiver - Connector C3371 Location (Floor Console) - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Connector C2153A Details - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Connector C2153B Details - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Connector C2153C Details - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Connector C2153D Details - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Connector C2153E Details - 2011 Edge Workshop Manual.pdf Remote Function Actuator (RFA) Module - Connectors Location (Behind Glovebox) - 2011 Edge Workshop Manual.pdf While I hope these documents cover all the bases for you, please let me know if you recognize a need for anything else. Presumably, your dealer's conclusion about ignition immobilization was based upon Diagnostic Trouble Codes (DTCs) present in your Edge's module(s). If you are personally going to embark upon chasing down potential cause(s), scan or get your Edge scanned to see what DTCs may be present, since they may be cited in the various Diagnosis and Testing documents linked above, and can indicate which Pinpoint Test to employ. Good luck!

-

Adding these, then, for your future reference... Document download links> Cooling Fans Wiring Diagram - Without Trailer Tow - 2007 Edge.pdf Cooling Fans Wiring Diagram - With Trailer Tow - 2007 Edge.pdf COOLING FAN MODULE - Connector C1554 Details and Photo - 2007 Edge.pdf COOLING FAN MODULE - Connector C1554 Location - 2007 Edge.pdf Good luck!

-

Welcome to the Forum, Ownerof2007 ! Given your long history of ownership, this may be an unnecessary question, but since you didn't mention it among your remedial actions... Have you verified the engine cooling fans are operating consistently? The following Workshop Manual sections may be helpful, especially since you've already replaced several of the items mentioned in the Diagnosis and Testing procedure... Document download links> Engine Cooling - Diagnosis and Testing - 2007 Edge Workshop Manual.pdf Cooling Fan Motor and Shroud - Removal and Installation - 2007 Edge Workshop Manual.pdf Cooling Fan Motor and Shroud - Enhanced Image 1 - 2007 Edge Workshop Manual.pdf Cooling Fan Motor and Shroud - Enhanced Image 2 - 2007 Edge Workshop Manual.pdf Cylinder Head Temperature (CHT) Sensor - Removal and Installation - 2007 Edge Workshop Manual.pdf Cylinder Head Temperature (CHT) Sensor - Enhanced Image - 2007 Edge Workshop Manual.pdf Cylinder Head Temperature (CHT) Sensor - Connector C107 Details and Photo - 2007 Edge.pdf Cylinder Head Temperature (CHT) Sensor - Connector C107 Location - 2007 Edge.pdf Lower Intake Manifold - In-Vehicle Removal and Installation - 2007 Edge Workshop Manual.pdf Lower Intake Manifold - Enhanced Illustration - 2007 Edge Workshop Manual.pdf Good luck!

-

Diagnosis and testing procedure from the 2012 Powertrain Control/Emissions Diagnosis Manual... P2196 - O2 Sensor Signal Biased/Stuck Rich - Bank 1, Sensor 1 Description: A heated oxygen sensor bank 1, sensor 1 (HO2S11) indicating rich at the end of a test is trying to correct for an over rich condition. This DTC sets when the fuel control system no longer detects switching for a calibrated amount of time. Possible Causes: HO2S harness short to voltage Water in the harness connector HO2S circuit open UO2SPC circuit open Corrosion Incorrect connections Excessive fuel pressure Leaking or contaminated fuel injectors EVAP purge valve stuck open Biased MAP sensor signal Incorrect learned ethanol content Contaminated MAF sensor Positive crankcase ventilation (PCV) system Contaminated oil Oil overfill Camshaft timing Damaged HO2S Damaged PCM Diagnostic Aids: Application Key On Engine Off Key On Engine Running Continuous Memory All GO to Pinpoint Test H. Document download link> Pinpoint Test H - Fuel Control.pdf Good luck!

-

I am finding no P1405 DTC. Diagnosis and testing procedure from the 2012 Powertrain Control/Emissions Diagnosis Manual... P1450 - Unable To Bleed Up Fuel Tank Vacuum Description: Monitors the fuel vapor vacuum and pressure in the fuel tank. This DTC sets when the evaporative emission (EVAP) running loss monitor detects excessive fuel tank vacuum with the engine running, but not at idle. Possible Causes: Blockages or kinks in the EVAP canister tube or EVAP canister purge outlet tube between the fuel tank, the EVAP purge valve and the EVAP canister Fuel filler cap stuck closed, preventing vacuum relief Capless fuel tank filler pipe damaged, preventing vacuum relief (if equipped) Contaminated fuel vapor elbow on the EVAP canister Restricted EVAP canister EVAP canister vent valve stuck partially or fully closed Plugged EVAP canister vent valve filter EVAP purge valve stuck open VREF circuit open Damaged FTP sensor Diagnostic Aids: Visually inspect the EVAP canister inlet port, EVAP canister vent valve filter, and EVAP canister vent hose assembly for contamination or debris. Check EVAP purge valve for vacuum leak. Application Key On Engine Off Key On Engine Running Continuous Memory All GO to Pinpoint Test HX. Please be aware this "HX" diagnostic procedure refers to several electrical connector designs used across various Ford models, including Edge... Document download links> Pinpoint Test HX - Evaporative Emission (EVAP) System and Monitor.pdf Fuel System - Diagnosis and Testing - 2012 Edge Workshop Manual.pdf Good luck!

-

Installation of a seat in EDGE SEL from TITANIUM

Haz replied to Yurez's topic in Accessories & Modifications

Heated Seat and Climate Controlled Seat wiring & connectors are identical for 2018 Edge and 2019 Edge. The driver's seat component would be the Driver Front Seat Module (DSM)... Document download links> Driver Front Seat Module (DSM) - Removal and Installation - 2019 Edge Workshop Manual.pdf Driver Front Seat Module (DSM) - Location - 2019 Edge.pdf For the passenger seat component, look for a part number on it and web-search the part number to identify that component. For additional clarification, I suggest you consult your local Ford dealership's Parts & Service personnel. I've supplied you all available resources on this topic. Good luck! -

The following Parking Lamps wiring diagram may be more useful to you than the previously supplied Headlamp Switch wiring diagram... Document download links> Body Control Module (BCM) - Parking Lamps Wiring Diagram - 2018 Edge.pdf Body Control Module (BCM) - Connector C2280B Details - 2018 Edge.pdf Body Control Module (BCM) - Connector C2280E Details - 2018 Edge.pdf Exterior Lighting - System Operation and Component Description - 2018 Edge Workshop Manual.pdf Good luck!

-

I located the 2018 Model Year multi-vehicle/multi-lingual Installation Instructions, which I pared down to Edge/English for you, and I've added relevant 2018 Edge Wiring Diagrams and Connectors info below... Document download links> Ambient Lighting Kit - SKCL8J-13E700-AA - 2018 Model Year Installation Instructions - Edited for Edge.pdf Factory-Installed Ambient Lighting Power Distribution Wiring Diagram - 2018 Edge.pdf Headlamp Switch to Body Control Module (BCM) Wiring Diagram - 2018 Edge.pdf Body Control Module (BCM) - Connectors C2280F & C2280G Attachment Locations on BCM - 2018 Edge.pdf Body Control Module (BCM) - Connector C2280F Details - 2018 Edge.pdf Body Control Module (BCM) - Connector C2280F Location - 2018 Edge.pdf Body Control Module (BCM) - Connector C2280G Details - 2018 Edge.pdf Body Control Module (BCM) - Connector C2280G Location - 2018 Edge.pdf Interior Lighting - System Operation and Component Description - 2018 Edge Workshop Manual.pdf Good luck!

-

Installation of a seat in EDGE SEL from TITANIUM

Haz replied to Yurez's topic in Accessories & Modifications

I have provided you an external download link to the requested 2018 Edge Climate Controlled Seat information via the Forum message system, due to Forum file-size limitations. Good luck! -

SSM 51823 - 2019-2023 Edge/Nautilus, 2020-2023 Escape/Corsair, 2021-2023 Bronco Sport, 2022-2023 Maverick - AWD - Chatter/Shudder During Low Speed Turning Events Some 2019-2023 Edge/Nautilus, 2020-2023 Escape/Corsair, 2021-2023 Bronco Sport, 2022-2023 Maverick vehicles equipped with all wheel drive (AWD) may exhibit chatter/shudder during low speed turning events. This may be due to fluid contamination in the rear drive unit (RDU). Drain and refill the RDU, refer to Workshop Manual Section (WSM) 205-02. Drive for 5 miles (8 km) in stop and go conditions with right and left turns and re-evaluate. If the issue is still present, continue with normal WSM diagnostics. For claiming, use base (4000) causal part. Document download links for Workshop Manual information referenced in SSM 51823> Differential Draining and Filling - General Procedures - 2019 Edge Workshop Manual.pdf Rear Drive Axle-Differential - Specifications - 2019 Edge Workshop Manual.pdf The above-linked documents are applicable and consistent for 2019-2023 Edge/Nautilus.

-

Remote Start Stopped working

Haz replied to Rob4652's topic in Alarms, Keyless Entry, Locks & Remote Start

Document download link> Charging System - 2.0L EcoBoost - System Operation and Component Description - 2017 Edge Workshop Manual.pdf Good luck! -

Manage Wi-Fi Networks Unavailable

Haz replied to jsalva04's topic in Audio, Backup, Navigation & SYNC

With your Edge lacking the ability to connect to Ford software update servers via Wi-Fi or 4G cellular telecom connections, in the future you will have to take your Edge to the dealership Service department for their technician to use a wired or Bluetooth connection to your Edge to evaluate if SYNC 4A -- or any other of your Edge's electronic modules -- are in need of a software update. Earlier versions of SYNC, up to SYNC 3, allowed owners to download SYNC updates over the Internet to a USB thumb-drive/memory card for transfer and installation to the vehicle's SYNC module/APIM -- but this is not possible with SYNC 4. In your Edge's case, the dealership technician will similarly download whatever update files that the Ford servers deem your Edge requires, and then perhaps use a USB memory device to transfer and install the needed update(s). This same process would be used on any vehicle equipped for over the air updates, but that vehicle is unable to receive the Ford Power-Up download -- perhaps due to corrupted software in the vehicle's TCU or Gateway module, or some other component issue. The SYNC software in your Edge shows an install date of 11/09/2022, which is your Edge's build date. The Panama version of Ford's Professional Technician System (PTS) website does not include any Connected Vehicle/OTA Software Update Dashboard, since Panama-market vehicles lack OTA capability. Looking at the USA PTS website, however, there are no pending software updates for your Edge's VIN. And all software updates are administered by VIN. For now, I'd say you have nothing to be concerned about! Good luck! -

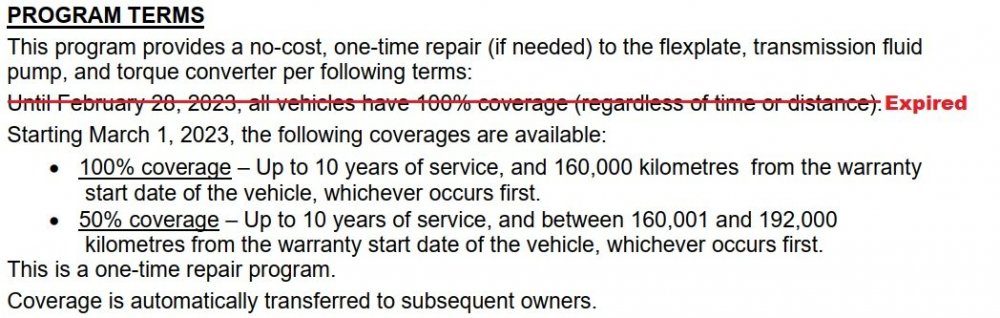

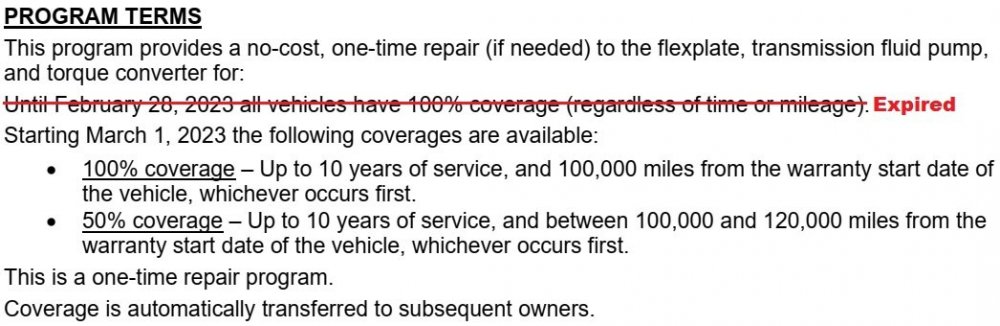

Customer Satisfaction 22N12- Flex Plate Crack on 2.0

Haz replied to All Hat No Cattle's topic in Recalls, TSBs & Warranty

It's worth noting, CSP 22N12 is not described as a one-time inspection program -- it's a one-time repair program. Meaning, CSP 22N12 is fulfilled after an eligible vehicle's Flexplate, Transmission Fluid Pump, and Torque Converter are replaced, after a rattling-symptom-based inspection reveals the originally installed Flexplate to be cracked, within the 100% coverage/50% coverage/time/distance Program Terms described below... United States CSP 22N12 Canada CSP 22N12 Good luck!

-ComponentLIST-2015EdgeWorkshopManual.jpg.5cd82b4d07e932e2dd084647c83565a5.jpg)

-ComponentLocation-2015EdgeWorkshopManual.thumb.jpg.b03f6f09d5119c90db01c0f7bb649e42.jpg)

-ComponentLIST-2015EdgeWorkshopManual.jpg.0025f311e82317216513bf1ee5729809.jpg)

-ComponentLocation-2015EdgeWorkshopManual.thumb.jpg.ba46e6eb51b6145a71566f1c2cbf60a4.jpg)

toAirFlowDoorActuatorsWiringDiagram.thumb.jpg.0f96a061008a8eb2f45d5095e185220f.jpg)

Illustration-BeneathDriverSeat.thumb.jpg.69c0e5e3a9ad74b35dd35bb50791bdac.jpg)

-BeneathPassengerSeat.thumb.jpg.3f4597e10356c5fc64990c6501b8e0ca.jpg)