Haz

Edge Member-

Posts

1,350 -

Joined

-

Last visited

-

Days Won

357

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

Attached below as PDF documents... Please note that Inline Connector C900 pinout document lacks these circuit descriptions for Module Communications-related pins: Good luck! Inline Connector C900 - Location View 1 - 2022 Edge.pdf Inline Connector C900 - Location View 2 - 2022 Edge.pdf Inline Connector C900 - Location View 3 - 2022 Edge.pdf Inline Connector C900 - Pin-Circuit Alpha-Numeric Identifier - 2022 Edge.pdf

-

Additional information attached below as PDF documents... Please let me know if any observed Diagnostic Trouble Code (DTC) or Symptom(s) indicates any Diagnostic Pinpoint Test(s) that may be useful toward your efforts, and I will supply. Good Luck! Controller Area Network (CAN) Module Communications Network - System Operation and Component Description - 2022 Edge Workshop Manual.pdf Controller Area Network (CAN) Module Communications Network - Diagnosis and Testing - 2022 Edge Workshop Manual.pdf

-

Welcome to the Forum @Jarekmucha! Attached below as PDF documents... Please let me know if you need additional module Connector details. Good Luck! Module Communications Network -Wiring Diagram Page 1 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 2 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 3 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 4 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 5 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 6 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 7 - 2022 Edge.pdf Module Communications Network -Wiring Diagram Page 8 - 2022 Edge.pdf Gateway Module - Connectors C4931A-B-C Location - 2022 Edge.pdf Gateway Module - Connectors C4931A - Pin-Circuit Details - 2022 Edge.pdf Gateway Module - Connector C4931B - Pin-Circuit Details - 2022 Edge.pdf Gateway Module - Connector C4931C - Pin-Circuit Details - 2022 Edge.pdf Remote Data Link Connector (DLC) - Connector C2122 - Pin-Circuit Details - 2022 Edge.pdf Remote Data Link Connector (DLC) - Connector C2122 - Location - 2022 Edge.pdf

-

SSM 53089 - Vehicles Equipped with SYNC4 - Intermittent Symptoms After All Available Software Updates Performed - Awareness of Solutions Being Developed Some vehicles equipped with SYNC4 may exhibit one or more of the following symptoms after all currently available accessory protocol interface module (APIM) software updates have been performed. - General system performance, stability, and intermittent system reboots. - Intermittent Wireless CarPlay or Android Auto function. - Phone related concerns with intermittent No Audio or Static. - Navigation/global positioning system (GPS) related concerns through CarPlay and Android Auto. - Alexa function consistency and stability. These symptoms may be due to the software in the APIM. Replacing the APIM will not resolve these symptoms for the customer. Before returning the vehicle to the customer, review the procedures within Workshop Manual, Section 415-00 and ensure the latest APIM software is installed. Refer to General Service Bulletin (GSB) 23-7146 for help determining the latest available level of software. IMPORTANT: some module software updates will only display as available on Ford Diagnosis and Repair System (FDRS) after prerequisite modules are updated. This may require the technician to update certain modules multiple times during the service visit, before the latest APIM software is accessible in FDRS. If symptoms continue after latest APIM software has been installed, inform customers that Ford is working on additional software enhancements which are expected to be delivered over-the-air (OTA) in Q1 2025. Software will update automatically if vehicle connectivity is enabled in the vehicle's settings. Schedule a service visit for customers who have disabled vehicle connectivity or who report that they did not receive the update in late Q1 2025. Monitor OASIS for additional information.

- 1 reply

-

- 4

-

-

-

Welcome to the Forum @Jim Goldsmith! Presuming you are referring to your Edge's interior mirror, the relevant Workshop Manual section is attached below as a PDF document... Good luck! Interior Rear View Mirror - Removal and Installation - 2020 Edge Workshop Manual.pdf

- 1 reply

-

- 2

-

-

TECHNICAL SERVICE BULLETIN 2.7/3.0L EcoBoost - Engine Oil Leak From The Crankshaft Rear Seal With Retaining Plate 24-2331 23 October 2024 Model: Ford 2021-2024 Bronco Engine: 2.7L EcoBoost Engine: 3.0L EcoBoost 2018-2024 Edge Engine: 2.7L EcoBoost 2020-2025 Explorer Engine: 3.0L EcoBoost 2018-2024 F-150 Engine: 2.7L EcoBoost 2024 Ranger Engine: 2.7L EcoBoost Engine: 3.0L EcoBoost Lincoln 2020-2025 Aviator Engine: 3.0L EcoBoost 2018-2023 Nautilus Engine: 2.7L EcoBoost Issue: Some 2018-2024 F150/Edge, 2018 MKX, 2019-2023 Nautilus, 2020-2025 Explorer/Aviator, 2021-2024 Bronco, and 2024 Ranger vehicles equipped with a 2.7L EcoBoost or a 3.0L EcoBoost engine may exhibit an engine oil leak from the crankshaft rear seal with retaining plate. This may be due to incorrect WSM installation instructions. To correct this condition, use this information along with the Service Procedure located within the WSM, Section 303-01 to correctly replace the crankshaft rear seal with retaining plate. Action: Follow the Service Procedure to correct the condition on vehicles that meet all the following criteria: • One of the following vehicles: - 2018-2024 F150 - 2018-2024 Edge - 2018 MKX - 2019-2023 Nautilus - 2020-2025 Explorer/Aviator - 2021-2024 Bronco - 2024 Ranger • Equipped with one of the following engines: - 2.7L EcoBoost - 3.0L EcoBoost • Engine oil leak coming from the crankshaft rear seal with retaining plate Special Tool(s) Seal Installer, Rear Main 303-1250 Warranty Status: Information Only. Repair/Claim Coding Causal Part: IN Condition Code: -1 Service Procedure Do not attempt to replace the rear crankshaft seal by itself. Order and install the rear crankshaft seal with retaining plate assembly (service base part# 6335). Prior to installing the crankshaft rear seal and retaining plate, the crankshaft surface must be cleaned using a dust-free cloth and Motorcraft® Metal Brake Parts Cleaner. Do not use abrasive materials as this can damage the sealing surface and affect the performance of the rear crankshaft seal. The engine block sealing surface must be completely clean and free of oil and debris in preparation for RTV silicone application. Clean the metal surface as outlined in the RTV Sealing Surface Cleaning and Preparation procedure. Refer to the WSM, Section 303-00 Engine System > General Information, General Procedures > RTV Sealing Surface Cleaning and Preparation. During installation of the crankshaft rear seal and retaining plate onto the crankshaft: • Lubricate the essential special service tool (ESST) outer surface, rear main seal inner surface, and the crankshaft sealing surface with new engine oil. • Once the crankshaft rear seal and retaining plate assembly is in place and during the removal of the ESST, closely inspect for seal roll. If a seal is rolled it will create an oil leak. Refer to Figure 1 for an example of a correctly installed seal, Figure 2 for an example of an incorrectly installed seal that has a partial roll, and Figure 3 for an example of a incorrectly installed seal with a fully rolled seal around the entire sealing surface. • Rear crankshaft seal with retainer plates are one-time-use parts. If the rear crankshaft seal becomes rolled during installation, the rear crankshaft seal with retaining plate assembly must be discarded. Figure 1: Figure 2: Figure 3: © 2024 Ford Motor Company All rights reserved. NOTE: The information in Technical Service Bulletins is intended for use by trained, professional technicians with the knowledge, tools, and equipment to do the job properly and safely. It informs these technicians of conditions that may occur on some vehicles, or provides information that could assist in proper vehicle service. The procedures should not be performed by "do-it-yourselfers". Do not assume that a condition described affects your car or truck. Contact a Ford or Lincoln dealership to determine whether the Bulletin applies to your vehicle. Warranty Policy and Extended Service Plan documentation determine Warranty and/or Extended Service Plan coverage unless stated otherwise in the TSB article. The information in this Technical Service Bulletin (TSB) was current at the time of printing. Ford Motor Company reserves the right to supersede this information with updates. The most recent information is available through Ford Motor Company's on-line technical resources. TSB 24-2331 - 2.7L & 3.0L EcoBoost - Engine Oil Leak From The Crankshaft Rear Seal With Retaining Plate.pdf Crankshaft Rear Seal with Retainer Plate - 2.7L EcoBoost - Removal and Installation - Edge Workshop Manual.pdf

-

SSM 53064 - 2024 Nautilus - Driver Seat And Steering Column Not Moving To Easy Entry Position After Setting Up A Client Profile Some 2024 Nautilus vehicles may exhibit a concern with the driver seat and steering column moving to the saved memory position instead of the easy entry position when approaching or unlocking the vehicle with the key fob. This condition may occur after setting up a client profile and is due to the driver front seat module (DSM) software. Inform customers that they can continue to drive the vehicle and that engineering is currently working on revised DSM software for this condition that is expected late Q4 2024. In the interim, easy entry will function if the key fob is unlinked from the customers personal profile by selecting the profile on the center display screen, pressing the edit icon, choosing ID Method, pressing Unlink Key Fob, and then selecting Unlink from the pop-up screen. The customers driver seat and steering column memory settings will no longer be saved to the key fob but can be recalled by using the memory switches on the door or on the center display screen. Monitor OASIS for additional information and schedule service appointments for customers once the repair becomes available.

-

General Service Bulletin 24-7110 - Wireless Accessory Charging Module (WACM) Aid To Improve Performance Summary This article is intended to aid dealers and to provide customer recommendations to resolve concerns of the phone indicating a "temperature - cool down prior to using" warning, an inoperative or slow charging, and/or an intermittent charging while using the WACM. Service Information The WACM inductively charges a single Qi 1.x (pronounced "chee") compatible mobile phone at rates of up to 15W of power. Not all phones are compatible with wireless charging and not all phones are compatible with Qi 1.x wireless charging. Specific considerations are: Possible Causes Of A Phone Indicating A "Temperature" Warning Phones naturally warm up when charging wirelessly and might display warnings such as “Phone needs to cool down” which is a phone internal overheating protection mechanism to protect the battery. This is not an indication of WACM malfunction. In addition, using Wireless Apple CarPlay or Android Auto in combination with wireless charging will often heat up the phone faster. The temperature at which each phone will show an overheating message is dependent of the phone’s brand, model, battery health and battery state of charge. Possible Causes Of Inoperative/Slow Or Intermittent Charging When placing a phone on the module, the phone State of Charge may appear to not change, raise slowly, decrease, or charging goes on and off repeatedly. The speed at which each phone charges is dependent on the phone’s brand, model, battery health and battery state of charge. Streaming maps, audio or calls through Wireless Apple Car Play or Wireless Android Auto can also cause slow charging. For additional information, see the full General Service Bulletin attached below as a PDF document... GSB 24-7110 - Wireless Accessory Charging Module (WACM) Aid To Improve Performance - 10-21-2024.pdf

-

Attached below as PDF documents, from the 2016 Edge Workshop Manual, providing an overview of removal and installation of the front & rear Door Glass Top Runs... Good luck! Front Door Glass Top Run - Removal and Installation - 2016 Edge Workshop Manual.pdf Rear Door Glass Top Run - Removal and Installation - 2016 Edge Workshop Manual.pdf

-

Special Service Message 53057 - 2024 Nautilus - Front Driver Door Can Not Be Unlocked Using Intelligent Access - Built On Or Before Jan 23, 2024 Some 2024 Nautilus vehicles built on or before Jan 23, 2024 may exhibit a condition where the front driver door can not be unlocked using the passive entry (Intelligent Access) feature. This may be due to the software in the body control module (BCM). To correct the condition, reprogram the BCM module using the latest software level of the Ford Diagnosis and Repair System (FDRS). For claiming, use causal part 15604 and applicable labor operations in Section 10 of the Service Labor Time Standards (SLTS) Manual.

-

2019 Ford Escape 1.5L bank 1 sensor 2 oxygen sensor

Haz replied to kevin kogut's topic in 2019-2020 Edge & Nautilius

@kevin kogut: As before, attached below as PDF documents are relevant sections from the 2019 Escape Workshop Manual... Please be aware that some numbered action-step descriptions may appear at the bottom of the page before the illustration to which it applies. 1.5L EcoBoost Engine Item Description 1 Turbocharger bypass valve solenoid 2 CMP sensor RH exhaust 3 ECT sensor 4 HO2S 5 Catalyst monitor sensor 6 CHT 2 (CHT2) sensor 7 CKP sensor 8 Wastegate actuator 9 VCT oil control solenoid exhaust Good luck! Catalyst Monitor (Oxygen) Sensor - 1.5L EcoBoost - Removal and Installation - 2019 Escape Workshop Manual.pdf Air Cleaner Outlet Pipe - 1.5L EcoBoost - Removal and Installation - 2019 Escape Workshop Manual.pdf Battery Tray - 1.5L EcoBoost - Removal and Installation - 2019 Escape Workshop Manual.pdf Exhaust Gas Oxygen Sensor Socket - Rotunda Part Number 303-476.pdf- 7 replies

-

- 1

-

-

- ford escape

- escape not edge

-

(and 1 more)

Tagged with:

-

2019 Ford Escape 1.5L bank 1 sensor 2 oxygen sensor

Haz replied to kevin kogut's topic in 2019-2020 Edge & Nautilius

Welcome to the Forum, @kevin kogut! Presumably, your Edge is a 2.0L EcoBoost rather that a 1.5L. Attached below as PDF documents are the Workshop Manual procedure and info on the recommended special tool... Good luck! Catalyst Monitor (Oxygen) Sensor - Removal and Installation - 2019 Edge Workshop Manual.pdf Exhaust Gas Oxygen Sensor Socket - Rotunda Part Number 303-476.pdf- 7 replies

-

- 2

-

-

- ford escape

- escape not edge

-

(and 1 more)

Tagged with:

-

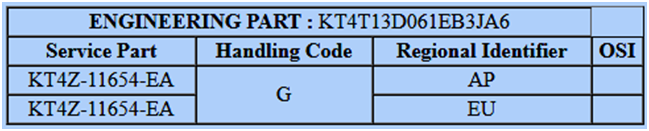

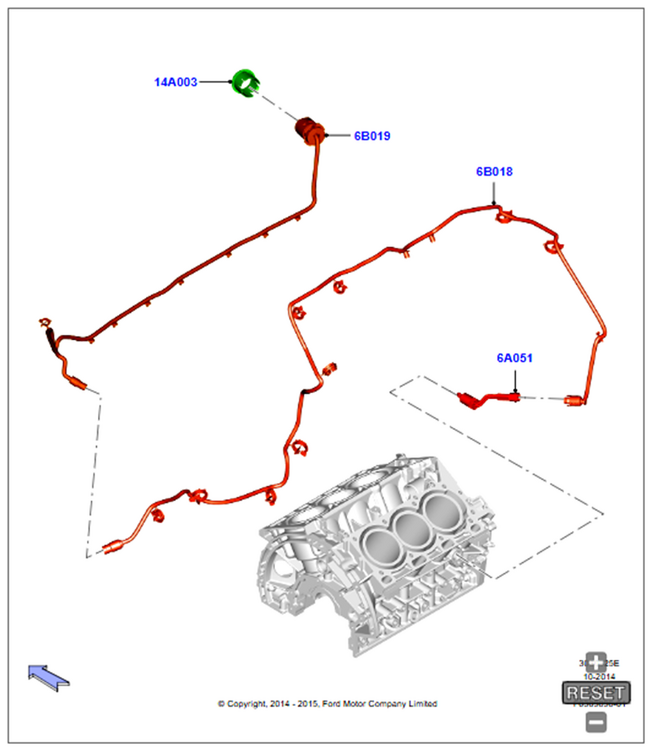

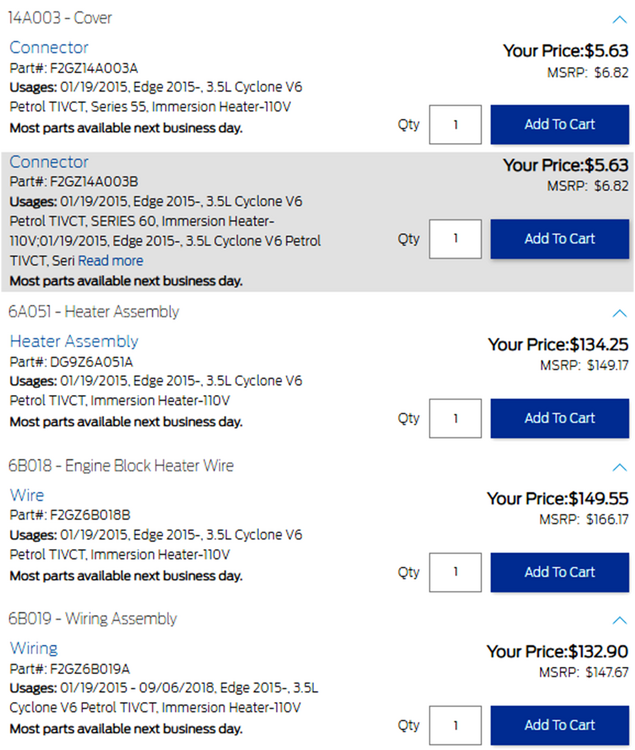

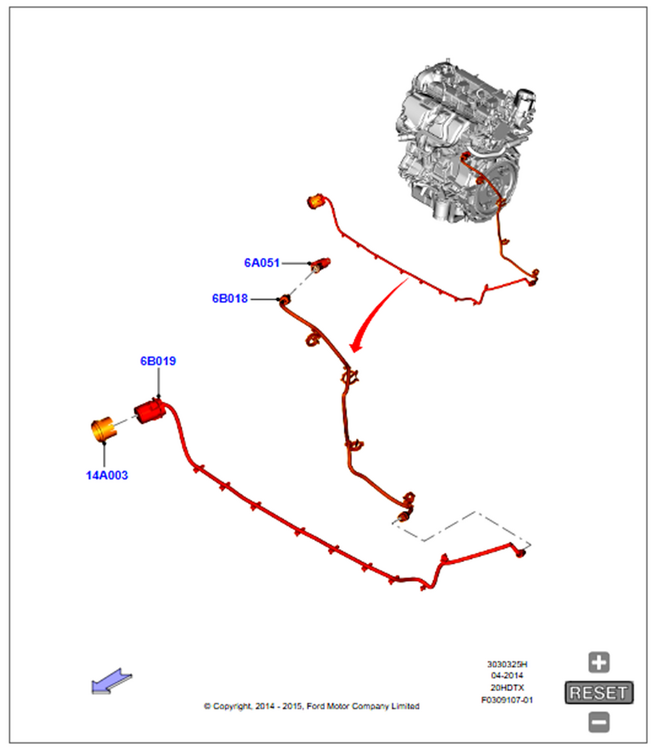

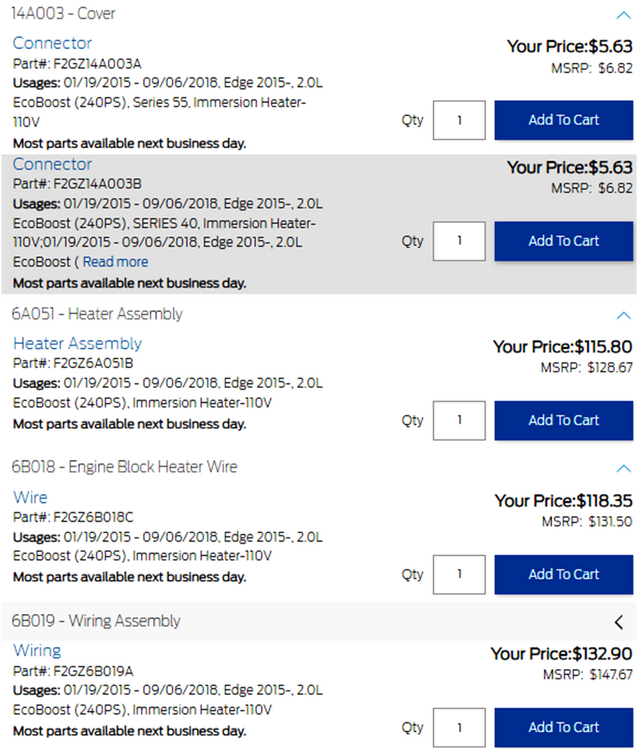

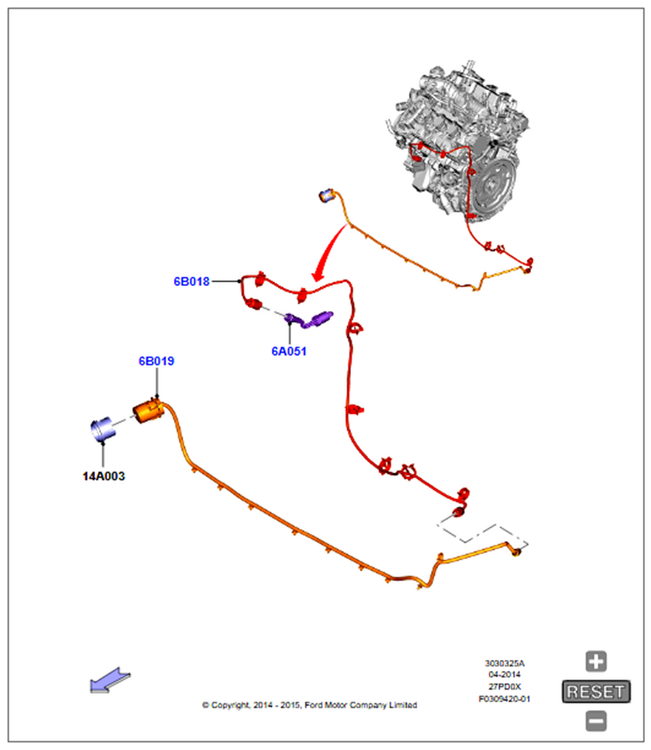

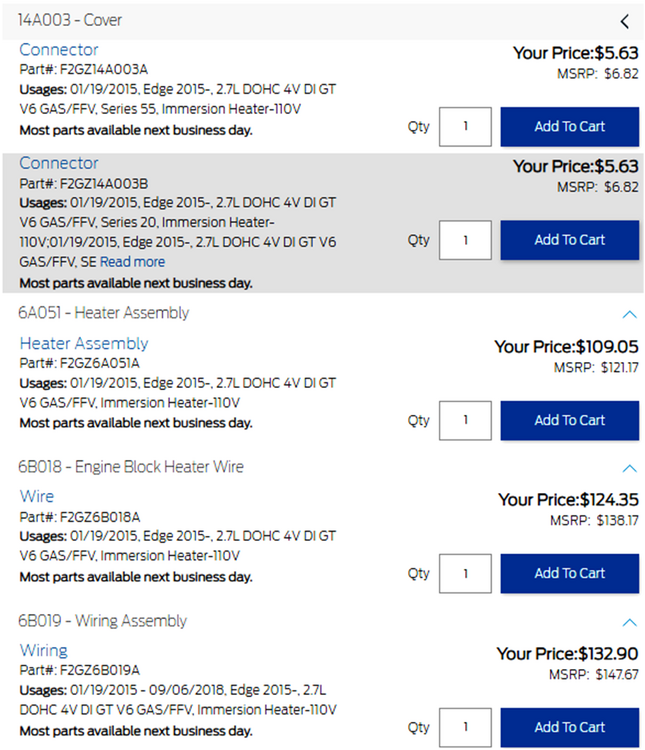

I cannot find any external lead-cord for factory-installed Edge block heaters depicted on Ford's online parts-selling site, FordParts. However, for anyone considering adding an engine block heater, here are parts numbers for various Edge engines... 3.5L & 3.7L TiVCT Duratec/Cyclone Engine 2.0L EcoBoost Engine 2.7L EcoBoost Engine Good luck!

-

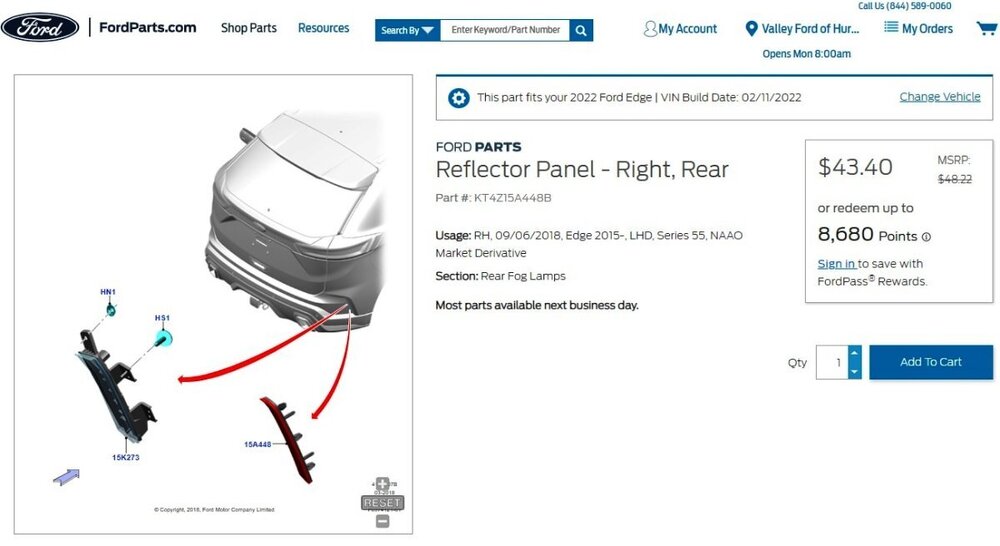

2022 Edge ST rear fog light

Haz replied to WilkiST's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

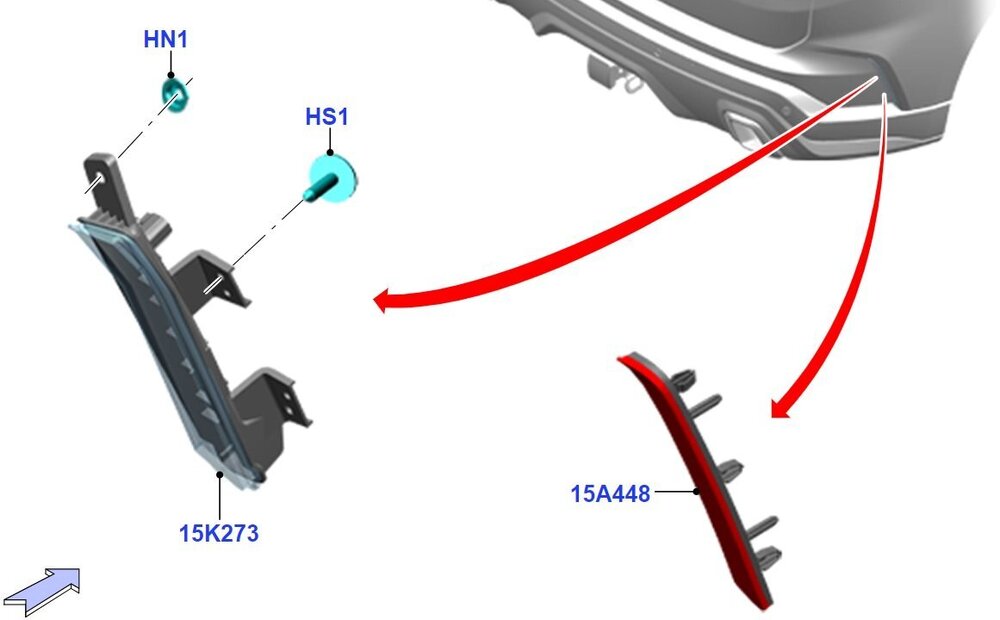

AP is the Regional Identifier for the Asia Pacific market. Using your Edge's North American market VIN to determine if any Trim Level differences in the installed Rear Bumper reflector assemblies, none are found -- meaning NA 2022 Edge SE/SEL/Titanium/ST-Line/ST all use the same Reflector Assembly... Link to web browser-zoomable/scrollable illustration shown in this FordParts Right Hand part listing The reflector-lens installed on North American Edges appears to use the same mount base as is provided for the Euro-Spec Rear Fog Lamp assemblies... ...with the North American reflector lens lacking the red semi-transparent lens portion of the Euro-Spec Rear Fog Lamp assemblies... Attached below as PDF documents are the Pin-Circuit descriptions for the North American & Euro-Spec versions of Headlamp Switch Connector C205, toward utilizing your installed Euro-spec headlamp switch's rear fog lamps button... Good luck! Headlamp Switch - Connector C205 Location - NA 2020 Edge.pdf Headlamp Switch - Connector C205 Pin-Circuit Details - NA 2020 Edge.pdf Headlamp Switch - Connector C205 Pin-Circuit Details - UK 2020 Edge.pdf -

2022 Edge ST rear fog light

Haz replied to WilkiST's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

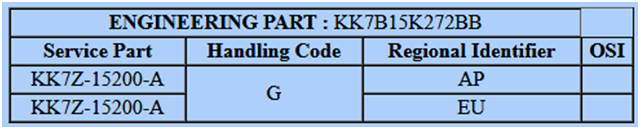

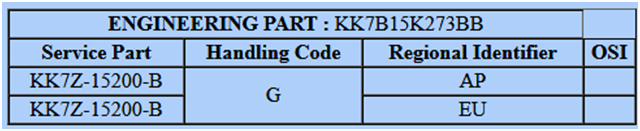

Searching UK used-vehicles-for-sale websites yields Euro-export ST-Line Edges with rear fog lamps installed, along with the headlamp switch that includes the rear fog lamps on-off button that you have already installed, photos here for Forum members awareness... I pulled VIN-based part numbers for a Euro-Spec export 2019 Edge ST-Line, where Engineering Part number is what was originally installed and Service Part number is the current Replacement Part, shown below... Right Hand Rear Fog Lamp Left Hand Rear Fog Lamp Headlamp Switch Assembly A Ford OEM Parts seller in your home country of Poland offers these same Euro-Spec Rear Fog Lamp part numbers for sale in the below links to their webpages... ODBLASK PRAWY TYŁ EDGE 2018- EUROPA_ 2270319 _ KK7B-15K272-AB _ KK7Z-15200-C ŚWIATŁO PRZECIWMGIELNE LEWE TYŁ EDGE 18- EU _ 2270321 _ KK7B-15K273-AB _ KK7Z-15200-D Per the Ali Express website photos and those on the above-linked webpages, the fog lamp light source apparently inserts into the open-top molded stem leading to the red semi-transparent lens portion of the mostly-reflector Rear Fog Lamp assemblies. While you indicate you may already have wiring information, attached below as PDF documents are Euro-Spec 2019 Edge wiring & connector diagrams for comparably aspiring Forum members... It's worth noting that the Euro-Spec Edge wiring diagram of the Body Control Module (BCM) includes a Field Effect Transistor (FET) protection device for the Rear Fog Lamps circuit, which may not be present in the North American BCM, though crosschecking North American versus European BCM part numbers, or real-world testing on your Edge may otherwise reveal. If you already possess all of this awareness, then at least it's now available to other Forum members. Good luck! Rear Fog Lamps - Wiring Diagram #1 - Euro-Export 2019 Edge.pdf Rear Fog Lamps - Wiring Diagram #2 - Euro-Export 2019 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280F - Euro-Spec 2019 Edge.pdf Rear Fog Lamp Left Hand - Connector C436 Location - Euro-Spec 2019 Edge.pdf Rear Fog Lamp Left Hand - Connector C436 Pins-Circuits Detail - Euro-Spec 2019 Edge.pdf Rear Fog Lamp Right Hand - Connector C437 Pins-Circuits Detail - Euro-Spec 2019 Edge.pdf Rear Fog Lamp Right Hand - Connector C437 Location - Euro-Spec 2019 Edge.pdf -

-

TECHNICAL SERVICE BULLETIN FHEV - Illuminated MIL With DTCs P0300, P0316 And/Or P051B Stored In The PCM 24-2319 08 October 2024 Model: Lincoln 2024 Nautilus Issue: Some 2024 Nautilus vehicles equipped with a FHEV powertrain may exhibit an illuminated MIL with DTCs P0300, P0316 and/or P051B stored in the PCM. This may be due to the software level of the PCM. To correct this condition, follow the Service Procedure to reprogram the PCM to the latest software level via the FDRS. Action: Follow the Service Procedure to correct the condition on vehicles that meet all of the following criteria: • 2024 Nautilus equipped with an FHEV powertrain • Illuminated MIL with DTC P0300, P0316 and/or P051B stored in the PCM Warranty Status: Eligible under provisions of New Vehicle Limited Warranty (NVLW)/Emissions Warranty/Service Part Warranty (SPW)/Service Part New Vehicle (SPNV)/Extended Service Plan (ESP) coverage. Limits/policies/prior approvals are not altered by a TSB. NVLW/Emissions Warranty/SPW/SPNV/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool. Labor Times Description Operation No. Time 2024 Nautilus FHEV: Retrieve DTCs And Reprogram The Appropriate Modules As Required By The Software Update And Service Procedure (Do Not Use With Any Other Labor Operations) MT242319 Actual Time Repair/Claim Coding Causal Part: RECALEM Condition Code: 04 Service Procedure 1. Connect a battery charger such as Rotunda GRX-3590 or DCA-8000 to the 12-volt battery. NOTE: To prevent the battery saver mode from activating on the vehicle, make sure the negative cable of the charger is installed on a chassis or engine ground, and not the 12-volt battery negative terminal. Do not have the vehicle plugged into high voltage battery charger during programming. This can cause incorrect module programming. Make sure only the 12-volt battery charger is installed. 2. Reprogram the PCM and SOBDMC using the latest level software level of the FDRS scan tool. Follow all on-screen instructions carefully to complete all coordinated module software updates. NOTE: Advise the customer this vehicle is equipped with an adaptive transmission shift strategy which allows the vehicle's computer to learn the transmission's unique parameters and improve shift quality. When the adaptive strategy is reset, the computer will begin a relearning process. This relearning process may result in firmer than normal upshifts and downshifts for several days. © 2024 Ford Motor Company All rights reserved. NOTE: The information in Technical Service Bulletins is intended for use by trained, professional technicians with the knowledge, tools, and equipment to do the job properly and safely. It informs these technicians of conditions that may occur on some vehicles, or provides information that could assist in proper vehicle service. The procedures should not be performed by "do-it-yourselfers". Do not assume that a condition described affects your car or truck. Contact a Ford or Lincoln dealership to determine whether the Bulletin applies to your vehicle. Warranty Policy and Extended Service Plan documentation determine Warranty and/or Extended Service Plan coverage unless stated otherwise in the TSB article. The information in this Technical Service Bulletin (TSB) was current at the time of printing. Ford Motor Company reserves the right to supersede this information with updates. The most recent information is available through Ford Motor Company's on-line technical resources.

-

SSM 53041 2024 Nautilus - Front Exterior Farewell Grille Lighting Event Randomly Occurring 30-60 Minutes After The Vehicle Is Parked - Built On Or Before 01-May-2024 Some 2024 Nautilus vehicles built on or before 01-May-2024 may exhibit a front exterior farewell grille lighting event randomly occuring 30-60 minutes after the vehicle is parked. This may be due to the software in the lighting driver control module (LDCM). To address this condition, reprogram the LDCMA (LH headlamp) and LDCMB (RH headlamp) using the Ford Diagnosis and Repair System (FDRS) > Lighting Driver Control Module Software Updates. For claiming, use causal part 13008 and applicable labor operations in section 10 of the Service Labor Time Standards (SLTS) manual. Optionally, claim additional programming (AP) time as needed.

- 1 reply

-

- 2

-

-

Just in case removing the Steering Column trim shroud is necessary to access Connector C2434. In this UK Edge Workshop Manual section, LH Drive is pictured, RH Drive similar, attached below as PDF document... Good luck! Steering Column Shrouds - Removal and Installation - 2017 Edge UK Workshop Manual.pdf

-

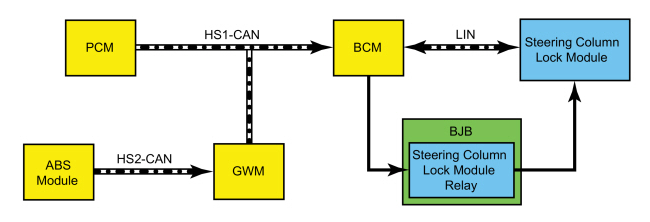

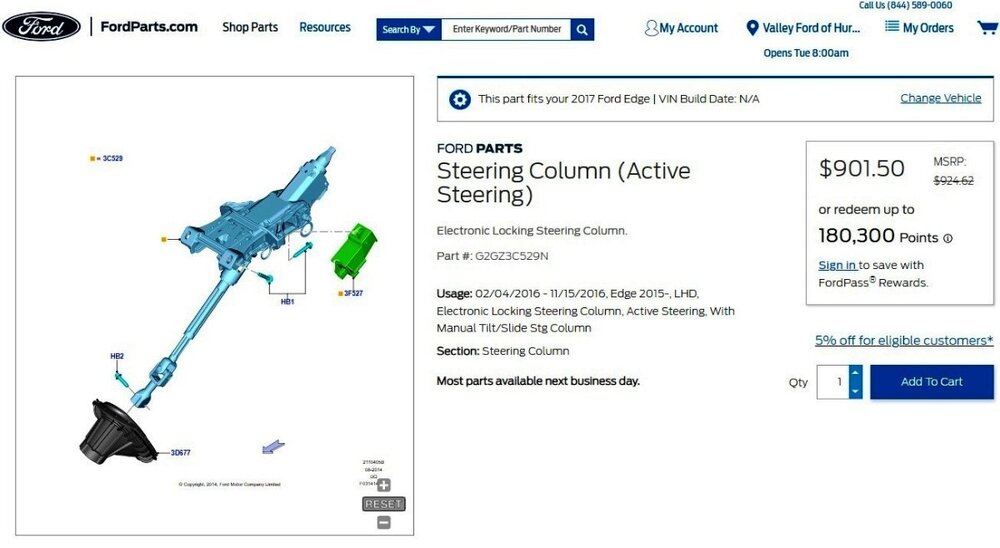

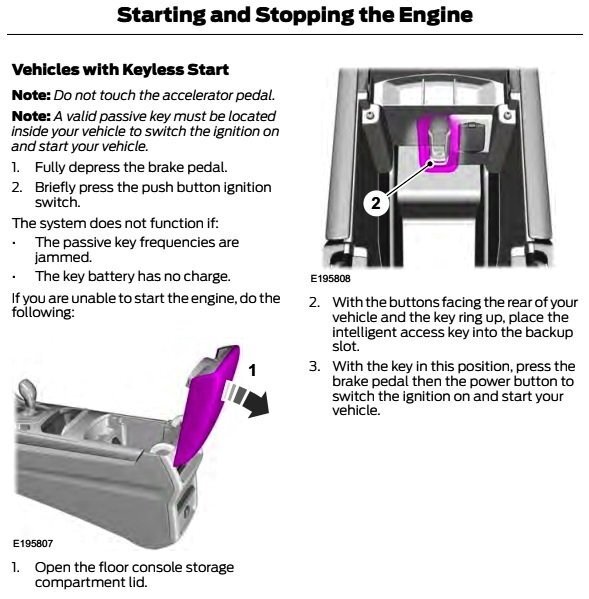

From the 2017 Edge UK Workshop Manual... System Diagram - Steering Column Lock (if equipped) Network Message Chart - Steering Column Lock (if equipped) BCM Network Input Messages Broadcast Message Originating Module Message Purpose Engine rpm data PCM Provides the BCM with the engine speed to indicate if the engine is running or not. Wheel rotation count ABS module Provides the BCM with the vehicle speed to indicate if the vehicle is moving or stationary. Steering Column Lock (if equipped) The steering column lock is used to deter vehicle theft by electronically locking the steering column. This prevents the steering wheel from being rotated to turn the front wheels. The steering column unlocks when: the passive entry feature is used to open the driver door. the driver door is opened after unlocking the vehicle with a RKE transmitter. the START/STOP button is pressed and a valid programmed passive key is detected. the remote start feature is activated. The steering column locks after: the ignition is turned off and 45 seconds have elapsed since the delayed accessory feature has turned off. 45 seconds have elapsed since the remote feature turned off the vehicle. The BCM controls the voltage provided to the steering column lock module using a relay (located in the BJB ) and communicates with it over a LIN . The BCM monitors inputs from various systems to determine when to send a command to lock or unlock the steering column. The steering column lock module locks and unlocks the steering column as directed by commands received from the BCM . If the BCM detects a fault from the steering column lock module or the LIN , the BCM prevents the vehicle from starting. The BCM does not provide power to the steering column lock module when the vehicle is moving or the engine is running. Steering Column Lock Messages (if equipped) The message center displays a message when the BCM detects a fault from the steering column lock module. The "Steering Malfunction" message displays when a fault with the electronic steering column lock system is present and must be diagnosed. The "Turn the wheel while starting" message displays when the steering column lock module is unable to unlock the steering column because of a high amount of torque against the lock (such as when the wheels are against a curb when the vehicle is shut off). The torque against the steering column lock must be relieved for the steering column to unlock. Turn the vehicle off, rotate and hold the steering wheel in one direction while turning the vehicle on. If the message displays again, turn the vehicle off, rotate and hold the steering wheel in the other direction while turning the vehicle on. Component Description Steering Column Lock Module (if equipped) The steering column lock module locks and unlocks the steering column based on commands received from the BCM . The steering column lock module monitors the position of the steering column lock and, if a fault is detected, reports the failure to the BCM . When the steering column lock module is replaced, the BCM must configured/trained to the new steering column lock module for the steering column lock module to operate correctly. The BCM sets a DTC if a fault is detected with the steering column lock module. Additionally, if the BCM is not configured to the steering column lock module, the steering column module keeps the column locked, a programming and/or configuration DTC sets and the vehicle does not start. BCM DTC Chart DTC Description Action B1026:04 Steering Column Lock: System Internal Failure DIAGNOSE all other Diagnostic Trouble Codes (DTCs) present. If no other Diagnostic Trouble Codes (DTCs) are present, INSTALL a new steering column lock module. REFER to: Steering Column Lock Module (211-05 Steering Wheel and Column Electrical Components, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:05 Steering Column Lock: System Programming Failure CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:09 Steering Column Lock: Component Failure INSTALL a new steering column lock module. REFER to: Steering Column Lock Module (211-05 Steering Wheel and Column Electrical Components, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:49 Steering Column Lock: Internal Electronic Failure INSTALL a new steering column lock module. REFER to: Steering Column Lock Module (211-05 Steering Wheel and Column Electrical Components, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:51 Steering Column Lock: Not Programmed CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:56 Steering Column Lock: Invalid / Incompatible Configuration CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:77 Steering Column Lock: Commanded Position Not Reachable INSTALL a new steering column lock module. REFER to: Steering Column Lock Module (211-05 Steering Wheel and Column Electrical Components, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:87 Steering Column Lock: Missing Message GO to Pinpoint Test L B1026:92 Steering Column Lock: Performance or Incorrect Operation GO to Pinpoint Test L B1026:93 Steering Column Lock: No Operation DIAGNOSE all other Diagnostic Trouble Codes (DTCs) present. If no other Diagnostic Trouble Codes (DTCs) are present, INSTALL a new steering column lock module. REFER to: Steering Column Lock Module (211-05 Steering Wheel and Column Electrical Components, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). B1026:96 Steering Column Lock: Component Internal Failure INSTALL a new steering column lock module. REFER to: Steering Column Lock Module (211-05 Steering Wheel and Column Electrical Components, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). PINPOINT TEST L: THE STEERING COLUMN IS ALWAYS OR NEVER LOCKED (IF EQUIPPED) NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.L1 CHECK FOR VOLTAGE TO THE STEERING COLUMN LOCK MODULE Ignition OFF. Disconnect Steering Column Lock Module C2434. Ignition ON. Measure: Positive Lead Measurement / Action Negative Lead C2434 Pin 2 Ground Is the voltage greater than 11 volts? Yes GO to L4 No VERIFY BJB fuse 48 (15A). If not OK, REFER to the Wiring Diagrams manual to identify the possible causes of the circuit short. If OK, GO to L2 L2 CHECK THE STEERING COLUMN LOCK MODULE RELAY COIL CONTROL CIRCUIT FOR AN OPEN Ignition OFF. Disconnect BJB C1035A. Disconnect BCM C2280C. Measure: Positive Lead Measurement / Action Negative Lead C1035A Pin 33 C2280C Pin 9 Is the resistance less than 3 ohms? Yes GO to L3 No REPAIR the circuit. L3 CHECK THE STEERING COLUMN LOCK MODULE RELAY VOLTAGE SUPPLY CIRCUIT FOR AN OPEN Ignition OFF. Measure: Positive Lead Measurement / Action Negative Lead C1035A Pin 41 C2434 Pin 2 Is the resistance less than 3 ohms? Yes INSTALL a new BJB relay module. No REPAIR the circuit. L4 CHECK THE STEERING COLUMN LOCK MODULE VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO VOLTAGE Disconnect BJB C1035A. Ignition ON. Measure: Positive Lead Measurement / Action Negative Lead C2434 Pin 2 Ground Is any voltage present? Yes REPAIR the circuit. No GO to L5 L5 CHECK THE STEERING COLUMN LOCK MODULE GROUND CIRCUIT FOR AN OPEN Ignition OFF. Measure: Click to display connectors Positive Lead Measurement / Action Negative Lead C2434 Pin 3 Ground Is the resistance less than 3 ohms? Yes GO to L6 No REPAIR the circuit. L6 CHECK THE STEERING COLUMN LOCK MODULE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO VOLTAGE Disconnect BCM C2280G. Ignition ON. Measure: Click to display connectors Positive Lead Measurement / Action Negative Lead C2434 Pin 4 Ground Is any voltage present? Yes REPAIR the circuit. No GO to L7 L7 CHECK THE STEERING COLUMN LOCK MODULE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR A SHORT TO GROUND Ignition OFF. Measure: Click to display connectors Positive Lead Measurement / Action Negative Lead C2434 Pin 4 Ground Is the resistance greater than 10,000 ohms? Yes GO to L8 No REPAIR the circuit. L8 CHECK THE STEERING COLUMN LOCK MODULE LIN (LOCAL INTERCONNECT NETWORK) CIRCUIT FOR AN OPEN Measure: Click to display connectors Positive Lead Measurement / Action Negative Lead C2434 Pin 4 C2280G Pin 25 Is the resistance less than 3 ohms? Yes INSTALL a new steering column lock module. CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). TEST the system for normal operation. If the concern is still present, GO to L9 No REPAIR the circuit. L9 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION Disconnect and inspect all BCM connectors. Repair: corrosion (install new connector or terminals - clean module pins) damaged or bent pins - install new terminals/pins pushed-out pins - install new pins as necessary Reconnect the BCM connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new BCM . REFER to: Body Control Module (BCM) (419-10 Multifunction Electronic Modules, Removal and Installation). CARRY OUT the BCM to ESCL (Electronic Steering Column Lock Training) procedure. REFER to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS) - Vehicles With: Keyless Vehicle System, General Procedures). No The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause of any connector or pin issues. Link to zoomable/scrollable exploded view illustration in below part-listing for LH Drive North American Edge, where green component is the module, to assist you toward locating its connector C2434 ... Relevant Workshop Manual, Wiring & Connector information attached below as PDF documents. Good luck! Diagnostic Pinpoint Test L - Steering Column Is Always or Never Locked - 2017 Edge NA Workshop Manual.pdf Steering Column Lock Module - Connector C2434 Location - 2017 Edge UK.pdf Steering Column Lock Module - Wiring Diagram - 2017 Edge UK.pdf Steering Column Lock Module - Power Distribution Wiring Diagram - 2017 Edge UK.pdf Steering Column Lock Module - Connector C2434 Pin-Circuit Details - 2017 Edge UK.pdf BATTERY JUNCTION BOX (BJB) - Connector C1035A Pin-Circuit Details - 2017 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280C Pin-Circuit Details - 2017 Edge.pdf BODY CONTROL MODULE (BCM) - Illustration Showing Connector C2280C Location - 2017 Edge.pdf

-

I agree, and I too, just found 2017 Edge Steering Gear photos... I also found a possible PSCM part number on a VIN-specific report, via Ford's UK Professional Technician System (PTS) website: F1GC-3F964-BA. It is possible that then current Service replacement has a different part number, so consulting with your local Ford Works dealer is necessary. Just for awareness, you could verify the part number, cost and availability, though the only DTC thus far is no communication -- which can involve connector, wiring, ground faults. If a DTC for internal failure of the module was present, it would be clear-cut that investing in a new PSCM is the right option -- presuming it's available apart from the Steering Gear assembly. I'll supply that VIN-specific report to you via Forum messaging. Good luck!

-

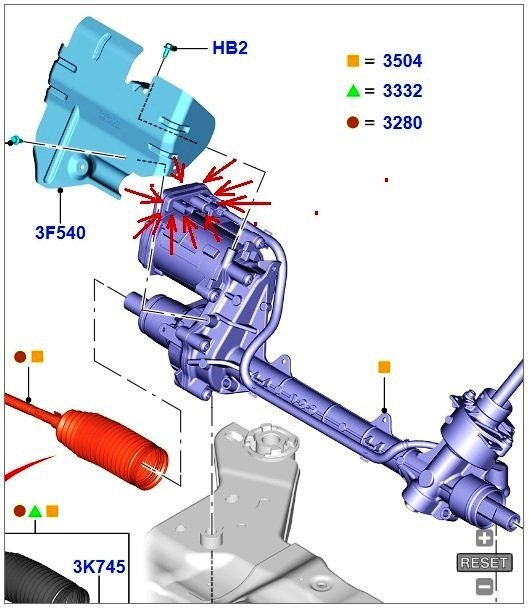

You will need at least a temporarily licensed copy of Forscan to reprogram a new PSCM with the appropriate As-Built data, which you can either copy from the currently installed PSCM, or verify that the PSCM contains the programing values shown in the As-Built Reprograming Data listing that I provided via Forum messaging. If you refer to the Module Configuration Workshop Manual document, the numerical line address for the PSCM will be shown in the table of various modules. Regarding a PSCM part number, I have not yet been able to find a replacement part number listed. I'm aware that the Steering Gear Removal and Installation Workshop Manual document indicates the PSCM provided with a new Steering Gear assembly must be appropriately programed with As-Built values obtained from the prior PSCM before it is removed. To me, this indicates the PSCM is provided in the assembly (PIA) replacing the faulty Steering Gear. On the other hand, one of the diagnostic procedures indicates "Replace the PSCM" as if the module can be separately obtained and is replaceable on the Steering Gear assembly, but again, I've not found a Service part number for the PSCM. Working from illustrations and based upon the depicted connector receptacles, I expect the PSCM is located in the area bounded by red arrows here... etho The full view of this cropped illustration is zoomable and scrollable using your web browser here. Neither the UK nor the North American Edge Workshop Manuals include any PSCM removal and installation procedure, which is unusual. If your diagnostic effort indicates PSCM replacement, then hopefully, inspecting your Edge's Steering Gear may yield a part number stickered or printed on its PSCM, along with some obvious module-mounting fasteners. Lacking Workshop Manual guidance, the question remains of how the PSCM interfaces with the Steering Gear assembly -- unless it's only via the laterally installed harness shown in the Steering Gear illustration, likely containing a C1463A or C1463B connector . Good luck!

Sensor-1.5LEcoBoost-Item5InIllustration-2019EscapeWorkshopManual.jpg.00664fa8d09330f2b062f64572592147.jpg)

-KT4Z15A448B-FordParts_com.thumb.jpg.1618738084782a820351142c6a1b53a8.jpg)