Haz

Edge Member-

Posts

1,350 -

Joined

-

Last visited

-

Days Won

357

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

Attention - there's an uptick in accounts being hacked

Haz replied to 1004ron's topic in Forum Help & Site Suggestions

-

2016 Edge requires new wheel hub to replace broken stud?

Haz replied to Raycaster's topic in Brakes, Chassis & Suspension

Per the 2016 Edge Workshop Manual, Wheel Studs are a replaceable part in Front & Rear hubs... Good luck! Wheel Studs - Removal and Installation - 2016 Edge Workshop Manual.pdf Front Wheel Bearing and Wheel Hub - Removal and Installation - 2016 Edge Workshop Manual.pdf Rear Wheel Bearing and Wheel Hub - FWD - Removal and Installation - 2016 Edge Workshop Manual.pdf Brake Disc - Removal and Installation - 2016 Edge Workshop Manual.pdf -

The original Forum announcement with Dealer Bulletin details... Emission Recall 24E10 - Certain 2015-2018 Edge with 3.5L Engine - Reprogram Powertrain Control Module (PCM) The Owner Letter you received mentions only "2016" because that's the Model Year of your Edge. I expect the "over time" revelation of the problem is why 2015-2018 Edges are now subject to the Recall. I do look forward to your personal assessment of the updated PCM software's affect upon your Edge's drivability! Good luck!

-

HD shocks on rear or rear coil overs for a '14 edge

Haz replied to Steve Hahn's topic in Brakes, Chassis & Suspension

Welcome to the Forum @Steve Hahn! Forum Search: Airlift air spring Good luck! -

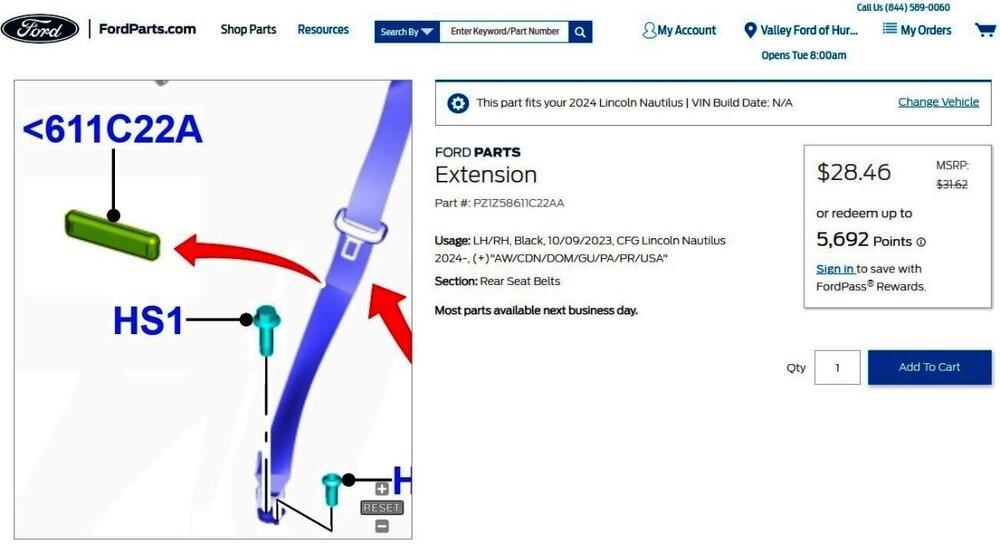

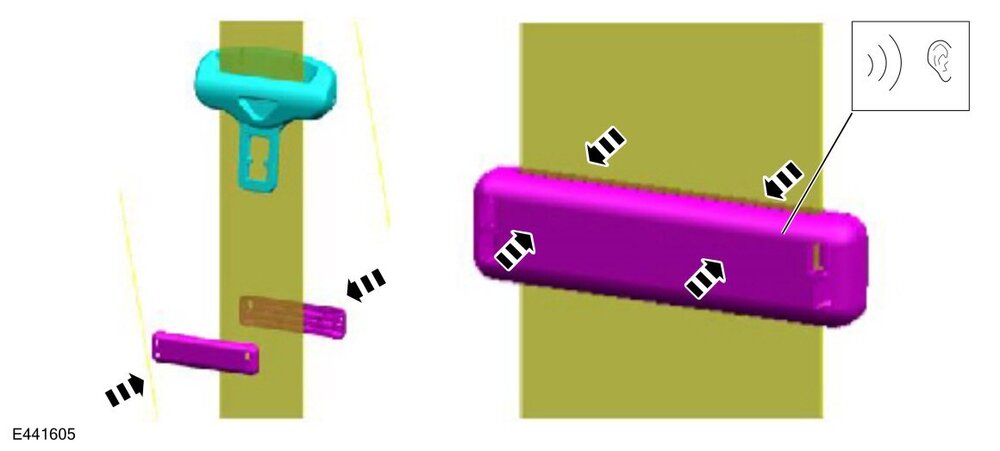

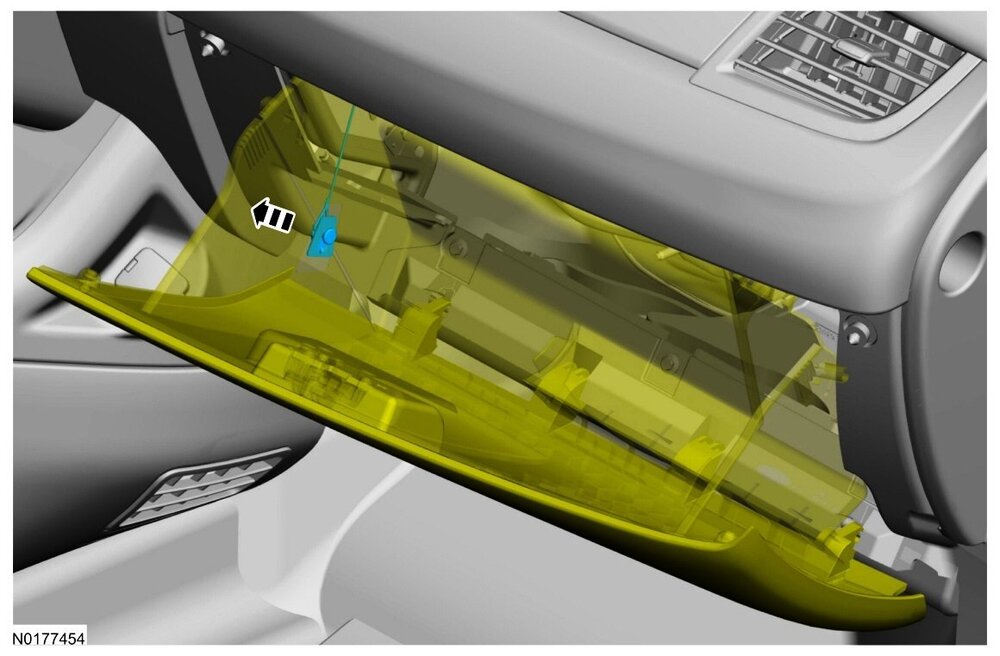

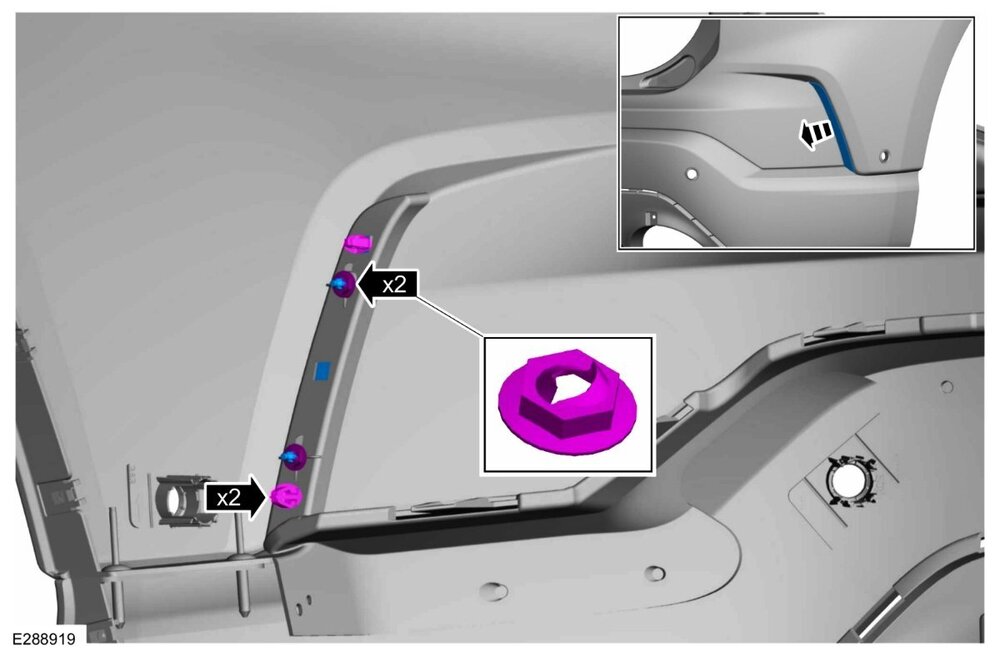

TECHNICAL SERVICE BULLETIN Rear Outboard Seat Belt Tongue Rattle Against Rear Interior Door Panel And/Or C-Pillar - Built On Or Before May 13, 2024 24-2258 08 November 2024 Model: Lincoln 2024 Nautilus Built on or before 13-May-2024 Markets: North American market only Issue: Some 2024 Nautilus vehicles built on or before 13-May-2024 may exhibit a rattle noise from the rear outboard seat area. This may be due to the outboard seat belt tongue making contact with either rear interior door panel and/or C-pillar moulding. To correct this condition, follow the Service Procedure to install a seat belt clip to reposition the seat belt tongue upward. Action: Follow the Service Procedure on vehicles that meet all of the following criteria:• 2024 Nautilus • Built on or before 13-May-2024 • Rear outboard seat belt retractors functioning normally and free of damage • Rear outboard seat belt tongue making contact with either rear interior door panel and/or C-pillar moulding Parts Service Part Number Claim Quantity Package Order Quantity Number in Package Description PZ1Z-58611C22-AA 2 2 1 Seatbelt Clip Claim Quantity refers to the total number of individual pieces required to repair the vehicle. Package Order Quantity refers to the amount of the service part number package(s) required to repair the vehicle. Number In Package refers to the number of individual pieces included in a service part number package. Warranty Status: Eligible under provisions of New Vehicle Limited Warranty (NVLW)/Service Part Warranty (SPW)/Service Part New Vehicle (SPNV)/Extended Service Plan (ESP) coverage. Limits/policies/prior approvals are not altered by a TSB. NVLW/SPW/SPNV/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool. Labor Times Description Operation No. Time 2024 Nautilus: Install And Adjust Clip On Seatbelt Webbing On Both (2) Sides Following The Service Procedure (Do Not Use With Any Other Labor Operations) 242258A 0.3 Hrs. Repair/Claim Coding Causal Part: 58611C22 Condition Code: 07 Service Procedure 1. Snap together and lock both seat belt clip halves over seat belt. (Figure 1) Figure 1 2. Slide clip and belt tongue upwards together along belt webbing until it contacts the belt tongue, and then upwards approximately 6 in. (150 mm). 3. Confirm the seat belt tongue is now 6 in. (150 mm) higher than the previously stowed position. Adjust seat belt tongue position again if necessary to achieve this distance. (Figure 2) Figure 2 4. Verify the seat belt tongue is now free from contacting either rear interior door panel and/or C-pillar molding. 5. Repeat Steps 1-4 for other side. © 2024 Ford Motor Company All rights reserved. NOTE: The information in Technical Service Bulletins is intended for use by trained, professional technicians with the knowledge, tools, and equipment to do the job properly and safely. It informs these technicians of conditions that may occur on some vehicles, or provides information that could assist in proper vehicle service. The procedures should not be performed by "do-it-yourselfers". Do not assume that a condition described affects your car or truck. Contact a Ford or Lincoln dealership to determine whether the Bulletin applies to your vehicle. Warranty Policy and Extended Service Plan documentation determine Warranty and/or Extended Service Plan coverage unless stated otherwise in the TSB article. The information in this Technical Service Bulletin (TSB) was current at the time of printing. Ford Motor Company reserves the right to supersede this information with updates. The most recent information is available through Ford Motor Company's on-line technical resources. TSB 24-2258 - Rear Outboard Seat Belt Tongue Rattle - 2024 Nautilus - Built On Or Before May 13, 2024.pdf

-

-

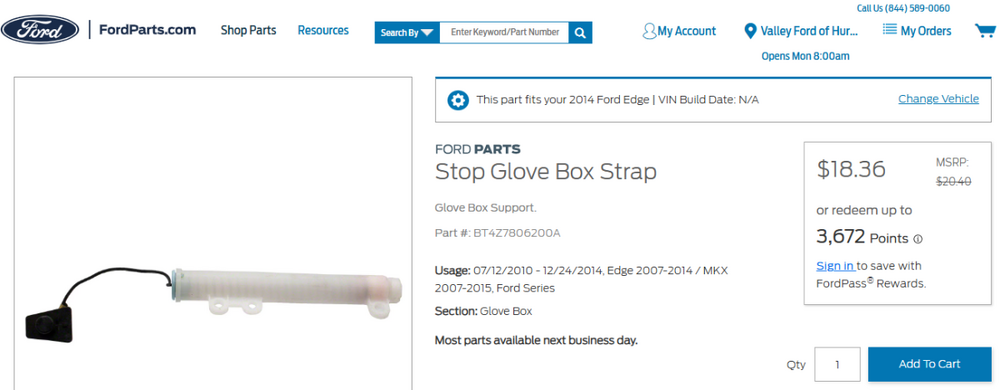

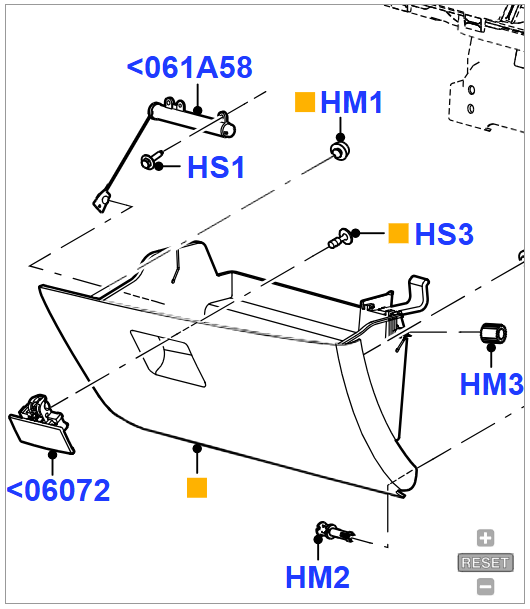

Welcome to the Forum @senciner! Link to this FordParts webpage The above-shown black plastic fitting -- which should be on the crimped metal cylinder shown in your photo on the frayed-end woven cord -- attaches to the glove compartment door to dampen its downward movement... Good luck!

-

If your 2020 Edge SEL is equipped with the factory Class II Trailer Tow Package, the following Special Service Message, issued effective October 7, 2021, may apply to the issue you describe... Good luck! SSM 50175 2015-2021 Edge, 2016-2018 MKX, 2019-2021 Nautilus - Parking Lamps Stay On And/Or Trailer Lights Flicker With Vehicle Turned Off Some 2015-2021 Edge, 2016-2018 MKX, and 2019-2021 Nautilus vehicles may exhibit the parking lamps stay on and/or the trailer lights flicker with vehicle turned off when a trailer is connected to the vehicle. This may be due to the software in the trailer module (TRM). To correct the condition, reprogram the TRM with the latest software of the appropriate Ford diagnostic scan tool. Use causal part 19H332 and applicable labor times from Section 10 of the Service Labor Time Standards (SLTS) Manual.

-

Welcome to the Forum @Dan_o! The VIN-based As-Built data for your Edge's factory installed Audio Front Control Module (ACM) is... 727-01-01 1801 3808 0089 727-01-02 0200 33 727-02-01 5B8C 727-03-01 3C6E 727-04-01 0001 0155 53DD If the currently installed ACM is truly faulty, and it is replaced with a working ACM from an Edge with an identical audio system, then the incoming ACM is likely programmed with the same As-Built values shown above. It would be prudent to verify these As-Built values using Forscan on the currently installed ACM, and to verify the As-Built values of the replacement ACM after it is installed. It is worth noting that a no-audio-sound condition can be caused by a properly working ACM which shuts down audio output in response to a shorted speaker circuit, per the 2017 Edge Workshop Manual, with emphasis added... Symptom Chart: Speakers Condition Possible Sources Actions No sound from all speakers Refer to the Pinpoint Test GO to Pinpoint Test F No Sound From All Speakers Normal Operation and Fault Conditions REFER to: Information and Entertainment System - System Operation and Component Description (415-00B Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Description and Operation). See ACM . When the ignition status message from the BCM indicates that the engine is cranking, the ACM mutes the audio output. A short to ground or short to voltage in the circuitry to one of the speakers may cause multiple speakers to lose sound due to the built-in overload protection feature of the ACM . In this case, a speaker fault DTC sets. DTC Fault Trigger Conditions DTC Description Fault Trigger Conditions DTC Type B1142:27 Ignition Status 1: Signal Rate of Change Above Threshold Set by the ACM when an error is detected in the ignition status message from the BCM during engine start. Continuous Possible Source ACM PINPOINT TEST F: NO SOUND FROM ALL SPEAKERS F1 VERIFY THAT THE ACM (AUDIO FRONT CONTROL MODULE) PASSES THE NETWORK TEST Using a diagnostic scan tool, perform the network test. Did the ACM pass the network test? Yes GO to F2 No REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing). See The ACM Does Not Respond To The Diagnostic Scan Tool. F2 CHECK FOR SPEAKER DIAGNOSTIC TROUBLE CODES (DTCS) Ignition ON. Using a diagnostic scan tool, perform the ACM self-test. Are any speaker fault Diagnostic Trouble Codes (DTCs) present? Yes REFER to the ACM DTC Chart in this section. ***INCLUDED BELOW THIS PINPOINT TEST*** No GO to F3 F3 CHECK FOR CORRECT ACM (AUDIO FRONT CONTROL MODULE) OPERATION Ignition OFF. Disconnect and inspect all the ACM connectors and related in-line connectors. Repair: corrosion (clean module pins or install new connectors or terminals) damaged or bent pins (install new terminals or pins) pushed-out pins (install new pins as necessary) Reconnect the ACM connectors and related in-line connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, discontinue this test and follow TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00B Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Removal and Installation). No The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause of any connector or pin issues. DTC Chart: ACM DTC Description Action B1142:27 Ignition Status 1: Signal Rate of Change Above Threshold GO to Pinpoint Test F B1A01:01 Speaker #1: General Electrical Failure For a LHF door speaker concern, GO to Pinpoint Test G For a LHF tweeter speaker concern, GO to Pinpoint Test H B1A01:11 Speaker #1: Circuit Short To Ground For a LHF door speaker concern, GO to Pinpoint Test G For a LHF tweeter speaker concern, GO to Pinpoint Test H B1A01:12 Speaker #1: Circuit Short To Battery For a LHF door speaker concern, GO to Pinpoint Test G For a LHF tweeter speaker concern, GO to Pinpoint Test H B1A01:13 Speaker #1: Circuit Open For a LHF door speaker concern, GO to Pinpoint Test G For a LHF tweeter speaker concern, GO to Pinpoint Test H B1A02:01 Speaker #2: General Electrical Failure For a RHF door speaker concern, GO to Pinpoint Test I For a RHF tweeter speaker concern, GO to Pinpoint Test J B1A02:11 Speaker #2: Circuit Short To Ground For a RHF door speaker concern, GO to Pinpoint Test I For a RHF tweeter speaker concern, GO to Pinpoint Test J B1A02:12 Speaker #2: Circuit Short To Battery For a RHF door speaker concern, GO to Pinpoint Test I For a RHF tweeter speaker concern, GO to Pinpoint Test J B1A02:13 Speaker #2: Circuit Open For a RHF door speaker concern, GO to Pinpoint Test I For a RHF tweeter speaker concern, GO to Pinpoint Test J B1A03:01 Speaker #3: General Electrical Failure For a RHR door speaker concern, GO to Pinpoint Test K For a RHR tweeter speaker concern, GO to Pinpoint Test L B1A03:11 Speaker #3: Circuit Short To Ground For a RHR door speaker concern, GO to Pinpoint Test K For a RHR tweeter speaker concern, GO to Pinpoint Test L B1A03:12 Speaker #3: Circuit Short To Battery For a RHR door speaker concern, GO to Pinpoint Test K For a RHR tweeter speaker concern, GO to Pinpoint Test L B1A03:13 Speaker #3: Circuit Open For a RHR door speaker concern, GO to Pinpoint Test K For a RHR tweeter speaker concern, GO to Pinpoint Test L B1A04:01 Speaker #4: General Electrical Failure For a LHR door speaker concern, GO to Pinpoint Test M For a LHR tweeter speaker concern, GO to Pinpoint Test N B1A04:11 Speaker #4: Circuit Short To Ground For a LHR door speaker concern, GO to Pinpoint Test M For a LHR tweeter speaker concern, GO to Pinpoint Test N B1A04:12 Speaker #4: Circuit Short To Battery For a LHR door speaker concern, GO to Pinpoint Test M For a LHR tweeter speaker concern, GO to Pinpoint Test N B1A04:13 Speaker #4: Circuit Open For a LHR door speaker concern, GO to Pinpoint Test M For a LHR tweeter speaker concern, GO to Pinpoint Test N B1A06:02 Speaker #6: General Signal Failure GO to Pinpoint Test O B1A06:11 Speaker #6: Circuit Short To Ground GO to Pinpoint Test O B1A06:12 Speaker #6: Circuit Short To Battery GO to Pinpoint Test O B1A06:13 Speaker #6: Circuit Open GO to Pinpoint Test O B1A56:21 Antenna: Signal Amplitude < Minimum If DTC B1A56:21 sets after running the bezel diagnostic tests, DISREGARD this DTC . This test is used for end of line or repair bay testing at the Ford plant. Each plant has its own assigned frequency and signal strength requirements. The running and passing of this test depends on local radio stations. If no local station is broadcasting on the required frequency, the test will fail. B1A89:11 Satellite Antenna: Circuit Short To Ground For a satellite radio concern, GO to Pinpoint Test B For a SIRIUS Travel Link concern, GO to Pinpoint Test C For a navigation concern (if equipped), GO to Pinpoint Test AB For a compass concern, GO to Pinpoint Test AC B1A89:13 Satellite Antenna: Circuit Open For a satellite radio concern, GO to Pinpoint Test B For a SIRIUS Travel Link concern, GO to Pinpoint Test C For a navigation concern (if equipped), GO to Pinpoint Test AB For a compass concern, GO to Pinpoint Test AC B1D19:49 Compact Disc Unit: Internal Electronic Failure GO to Pinpoint Test Y B1D19:4B Compact Disc Unit: Over Temperature GO to Pinpoint Test Y U0100:00 Lost Communication With ECM/PCM "A": No Sub Type Information GO to Pinpoint Test AE U0140:00 Lost Communication With Body Control Module: No Sub Type Information GO to Pinpoint Test AF U0155:00 Lost Communication With Instrument Panel Cluster (IPC) Control Module: No Sub Type Information GO to Pinpoint Test AH U0253:00 Lost Communication With Accessory Protocol Interface Module: No Sub Type Information GO to Pinpoint Test AI U0256:00 Lost Communication With Front Controls Interface Module “A”: No Sub Type Information GO to Pinpoint Test AJ U0257:00 Lost Communication With Front Controls / Display Interface Module: No Sub Type Information GO to Pinpoint Test AK U201A:51 Control Module Main Calibration Data: Not Programmed This DTC sets due to an incomplete or incorrect ACM PMI . CHECK the vehicle service history for recent service actions related to the ACM . If there have been recent service actions with the ACM , INSTALL As-Built data from Professional Technician Society (PTS), following the diagnostic scan tool instructions under Module Programming>As-Built. REFER to: Module Configuration - System Operation and Component Description (418-01 Module Configuration, Description and Operation). If there have been no recent service actions, the ACM has failed to retain configuration data. INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation). U2100:00 Initial Configuration Not Complete: No Sub Type Information This DTC sets due to an incomplete or incorrect ACM PMI . CHECK the vehicle service history for recent service actions related to the ACM . If there have been recent service actions with the ACM , INSTALL As-Built data from Professional Technician Society (PTS), following the diagnostic scan tool instructions under Module Programming>As-Built. REFER to: Module Configuration - System Operation and Component Description (418-01 Module Configuration, Description and Operation). If there have been no recent service actions, the ACM has failed to retain configuration data. INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation). U2101:00 Control Module Configuration Incompatible: No Sub Type Information This DTC sets due to an incomplete or incorrect ACM PMI . CHECK the vehicle service history for recent service actions related to the ACM . If there have been recent service actions with the ACM , INSTALL As-Built data from Professional Technician Society (PTS), following the diagnostic scan tool instructions under Module Programming>As-Built. REFER to: Module Configuration - System Operation and Component Description (418-01 Module Configuration, Description and Operation). If there have been no recent service actions, the ACM has failed to retain configuration data. INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation). U3000:41 Control Module: General Checksum Failure CLEAR the DTC . WAIT at least 10 seconds. REPEAT the self-test. If DTC U3000:41 is retrieved again, INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation). U3000:42 Control Module: General Memory Failure CLEAR the DTC . WAIT at least 10 seconds. REPEAT the self-test. If DTC U3000:42 is retrieved again, INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation). U3000:96 Control Module: Component Internal Failure CLEAR the DTC . WAIT at least 10 seconds. REPEAT the self-test. If DTC U3000:96 is retrieved again, INSTALL a new ACM . REFER to: Audio Front Control Module (ACM) (415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation). U3003:16 Battery Voltage: Circuit Voltage Below Threshold GO to Pinpoint Test AL U3003:17 Battery Voltage: Circuit Voltage Above Threshold GO to Pinpoint Test AM If Forscan reveals any Diagnostic Trouble Codes (DTCs) present in the ACM that require additional Pinpoint Test diagnostics, report back here and I will supply any needed Test(s). Related Workshop Manual sections are attached below as PDF documents... Good luck! Information and Entertainment System - 9-Speaker System Operation and Component Description - 2017 Edge Workshop Manual.pdf Information and Entertainment System - 9-Speaker System Component Location - 2017 Edge Workshop Manual.pdf Information and Entertainment System - Bezel Diagnostics - 2017 Edge Workshop Manual.pdf Audio Front Control Module (ACM) - Removal and Installation - 2017 Edge Workshop Manual.pdf Front Display Interface Module (FDIM) - Removal and Installation - 2017 Edge Workshop Manual.pdf Front Controls Interface Module (FCIM) - Removal and Installation - 2017 Edge Workshop Manual.pdf 2017 Edge Workshop Manual - Module Configuration - System Operation and Component Description.pdf

-

Engine Coolant Over Tempreture ERROR

Haz replied to NelsonPM33's topic in Interior, A.C., Heat, Interior Trim

@NelsonPM33: Just print the PDF documents, print this discussion, and then provide it all to your Mechanic, who's job it is to deal with the complexity of your Edge's issue. Good luck!- 4 replies

-

- 1

-

-

- engine coolant over temp

- 2.7 ecoboost

-

(and 2 more)

Tagged with:

-

Lane Keeping Assistant won't turn off!

Haz replied to Rchalk's topic in Interior, A.C., Heat, Interior Trim

@Rchalk: When ACC was mentioned, I should have recognized your Edge was equipped with Co-Pilot360+... Good luck! -

Lane Keeping Assistant won't turn off!

Haz replied to Rchalk's topic in Interior, A.C., Heat, Interior Trim

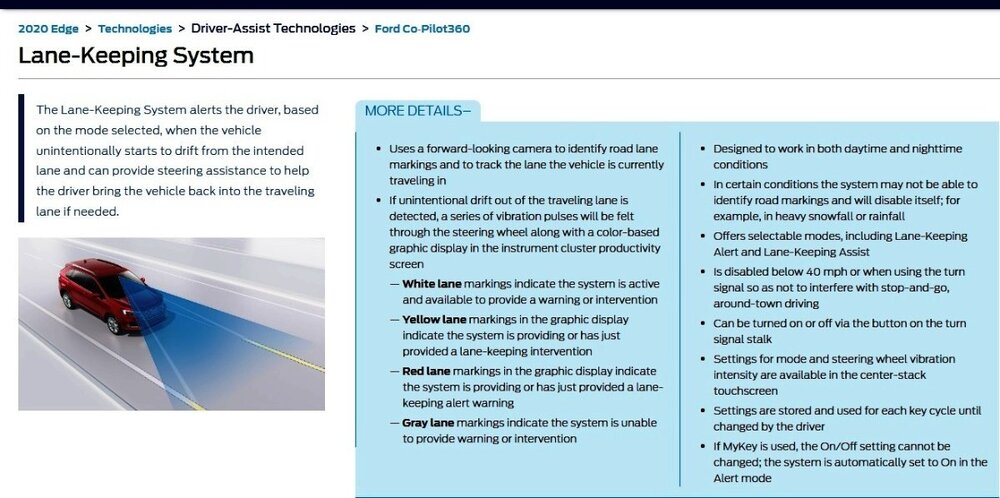

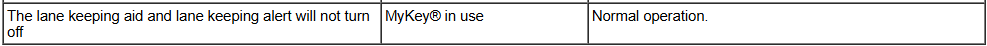

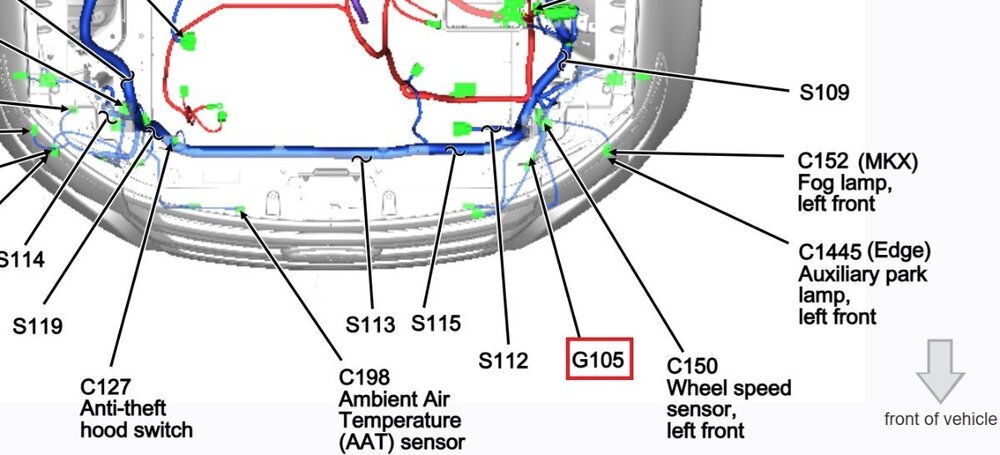

From the 2020 Edge Workshop Manual with emphasis added... Lane Keeping System Operation The lane keeping system is turned on and off using the lane keeping system switch located on the LH steering column multifunction switch. The lane keeping system switch is directly connected to the SCCM . The last known on/off setting for the lane keeping system is recalled every time the key is turned on. When a MyKey® is in use, the system defaults the lane keeping alert mode to on and cannot be turned off. When the system is on, it is active only when the vehicle speed is above 64 km/h (40 mph) and at least one lane marking can be detected by the camera. The system can be turned off at any time by pressing the lane keeping system switch. If the lane keeping system switch is pressed when a MyKey® is in use, the IPC message center will display a message informing the driver that the system is on. Looking to the above MyKey references - If you have more than one key, for your Edge, is the Lane Keeping System (LKS) on/off behavior issue the same for each key? Looking to the above last known on/off setting reference - If you deactivate ACC and then shut down your Edge, and then you restart the vehicle and activate ACC, is the LKS then On or Off? Toward your desire to perform a LKS reset - The Image Processing Module A (IPMA) power is protected by Body Control Module fuse F36 15-amp, which also protects the Auto Dimming Interior Mirror and Heated Rear Seat Module LH circuits. LKS Workshop Manual sections and Wiring/Fuse diagrams are attached below as PDF documents... Good luck! Lane Keeping System - System Operation and Component Description - 2020 Edge Workshop Manual.pdf Lane Keeping System - Overview - 2020 Edge Workshop Manual.pdf Lane Keeping System - Component Location - 2020 Edge Workshop Manual.pdf Image Processing Module A (IPMA) - Power Distribution Wiring Diagram - 2020 Edge.pdf Body Control Module (BCM) - Fuse Location Illustration - 2020 Edge.pdf Body Control Module (BCM) - Fuse-Circuits Legend - 2020 Edge.pdf Lane Keeping System (LKS) - Diagnostic Trouble Code (DTC) & Symptom Charts - 2020 Edge Workshop Manual.pdf 2020 Edge Settings & MyKey.pdf -

Welcome to the Forum @Maso125! From the below-attached 2007 Edge Workshop Manual procedure, with emphasis added... Cooling System Filling and Bleeding NOTICE: Use the vacuum cooling system filler to fill the cooling system, then carry out the remaining steps to bleed all the air from the cooling system. Failure to follow these instructions can leave air in the cooling system which may damage the engine or cooling system. Good luck! Cooling System Draining, Filling and Bleeding - General Procedures - 2007 Edge Workshop Manual.pdf

-

Welcome to the Forum @Traumajunkie46! From the 2016 Edge Workshop Manual, attached below as PDF documents... Good luck! Ignition Coil-On-Plug - Removal and Installation - 3.5L Duratec - 2016 Edge Workshop Manual.pdf Air Cleaner Outlet Pipe - Removal and Installation - 3.5L Duratec - 2016 Edge Workshop Manual.pdf Engine Overview - Description and Operation - 3.5L Duratec - 2016 Edge Workshop Manual.pdf Upper Intake Manifold - Removal and Installation - 3.5L Duratec - 2016 Edge Workshop Manual.pdf Quick Release Coupling - General Procedures - 3.5L Duratec - 2016 Edge Workshop Manual.pdf

-

Welcome to the Forum @tiggerose! From the 2017 Edge Workshop Manual, attached below as a PDF document... Good luck! Loadspace Trim Panel Cargo Net Hook - Removal and Installation - 2017 Edge Workshop Manual.pdf

-

@BMWR1200c: For your technical awareness, attached below as PDF documents... Good luck! Rain Sensor - Removal and Installation - 2020 Edge Workshop Manual.pdf Image Processing Module A (IPMA) - Removal and Installation - 2020 Edge Workshop Manual.pdf

-

SSM 53099 - 2024 Nautilus - Autofold Mirrors Inoperative After Performing FSA 24C24 Some 2024 Nautilus customers may notice the side mirror autofold feature inoperative after FSA 24C24 has been completed. This may be due to the feature defaulting to off after the driver door module (DDM) and passenger door module (PDM) software has been updated per the FSA. If this concern occurs it may be necessary to turn this feature back on in the vehicle. To regain the auto-fold power mirror function, go to Apps (icon with six dots on the left side of the center display screen) > Settings > Vehicle > Mirrors > Autofold and if the setting is turned off toggle it on. If the setting is already on, toggle it off then back on. Do this for each personal profile that has been set up in the vehicle including the guest profile. For information on the referenced Field Service Action (FSA) 24C24, see... Compliance Recall 24C24 - Certain 2024 Nautilus + Ranger - Power Windows May Pinch - Software Update to Driver & Passenger Door Modules

-

Related information attached below as PDF documents... Good luck! Halogen Headlamps - BCM to Lamps Wiring Diagram - 2012 Edge.pdf HEADLAMP, LEFT - Connector C1021A Pin-Circuit Details - 2012 Edge.pdf HEADLAMP, RIGHT - Connector C1041A Pin-Circuit Details - 2012 Edge.pdf HEADLAMP, RIGHT - Ground G107 Location - 2012 Edge.pdf Ground G107 - Wiring Diagram - 2012 Edge.pdf

-

Engine Coolant Over Tempreture ERROR

Haz replied to NelsonPM33's topic in Interior, A.C., Heat, Interior Trim

Welcome to the Forum @NelsonPM33! Your 2016 Edge Sport is equipped with a virtual Engine Coolant Gauge... ...which the 2016 Edge Workshop Manual describes as operating in this way with emphasis added... Placing your device cursor over underlined acronyms may yield popup full-words descriptions of the acronyms. Virtual Temperature Gauge The IPC uses 2 messages to control the temperature gauge. The first is the engine coolant temperature data, which provides the current engine temperature input to the PCM . The second message is the engine overheat indication request, which is sent by the PCM to the IPC when an overheating condition exists. When the IPC receives the engine overheat indication request message, the IPC sends the temperature gauge to full hot and turns on the over-temperature warning indicator. The IPC receives all the temperature gauge inputs from the GWM over the HS-CAN3 . The GWM receives the engine coolant temperature data and the engine overheat indication request messages from the PCM over the HS-CAN1 . If the engine coolant temperature data or engine overheat indication request messages are missing for less than 5 seconds, the IPC defaults the temperature gauge to the last indication state, based upon the last message received. If the engine coolant temperature data or engine overheat indication request messages are missing for 5 seconds or longer, the IPC defaults the temperature gauge to the full hot position. The following diagnostic Pinpoint Test B provides guidance on scanning your Edge's virtual-gauge-involved electronic modules for Diagnostic Trouble Codes (DTCs) that may describe the root cause of possible missing engine coolant data messages that are defaulting your Edge's virtual temperature gauge to full hot / overheated condition... A Virtual Gauge (AWD , Tachometer Or Temperature), Is Inoperative Normal Operation and Fault Conditions See Temperature Gauge. REFER to: Instrument Panel Cluster (IPC) - System Operation and Component Description (413-01 Instrumentation, Message Center and Warning Chimes, Description and Operation). ***ATTACHED AT BOTTOM OF THIS POST*** Temperature Gauge If the engine coolant temperature data or engine overheat indication request messages are missing for less than 5 seconds, the IPC defaults the temperature gauge to the last indication state, based upon the last message received. If the engine coolant temperature data or engine overheat indication request messages are missing for 5 seconds or longer, the IPC defaults the temperature gauge to the full hot position. Possible Sources Communication concern GWM concern PCM input concern IPC PINPOINT TEST B: A VIRTUAL GAUGE (AWD (ALL-WHEEL DRIVE) , TACHOMETER OR TEMPERATURE), IS INOPERATIVE B1 VERIFY THE IPC (INSTRUMENT PANEL CLUSTER) IS SET TO DISPLAY THE GAUGE Ignition ON. NOTE: The IPC and message center navigation can be found in the Owner's Literature. Using the message center controls, make sure the IPC is set to display the gauge in question. Is the IPC set to display the gauge? Yes GO to B2 No The virtual gauge is operating correctly. The IPC was not set to display the gauge in question. B2 PERFORM THE IPC (INSTRUMENT PANEL CLUSTER) SELF-TEST Using a diagnostic scan tool, perform the IPC self-test. Check for recorded Diagnostic Trouble Codes (DTCs) from the IPC self-test. Are any Diagnostic Trouble Codes (DTCs) recorded? Yes REFER to DTC Chart: IPC in this section. No GO to B3 B3 PERFORM THE PCM (POWERTRAIN CONTROL MODULE) SELF-TEST Using a diagnostic scan tool, perform the PCM self-test. Check for recorded Diagnostic Trouble Codes (DTCs). Are any Diagnostic Trouble Codes (DTCs) recorded? Yes Refer to the appropriate section in Group 303for the procedure. No GO to B4 B4 CHECK THE GWM (GATEWAY MODULE A) DIAGNOSTIC TROUBLE CODES (DTCS) Using a diagnostic scan tool, check the GWM Continuous Memory Diagnostic Trouble Codes (DTCs). Are any Diagnostic Trouble Codes (DTCs) recorded? Yes REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing). No Click here to access Guided Routine (IPC). If you don't have immediate access to an electronic scanner DTC code reader, hopefully a local auto parts store or your local Ford dealer may offer that scanning service, but in the meantime, you can perhaps use Dealer Test Mode to see if the Instrument Panel Cluster (IPC) is reporting any current or historical DTCs... Dealer Test Mode NOTE: The table lists the displays as they appear when navigating using the down arrow button. To enter the IPC engineering test mode or dealer test mode, begin with the ignition OFF. Press and hold the LH steering wheel switch OK button. Place the ignition ON and continue to hold the button for 5-8 seconds until the display indicates Test or Gauge Sweep. Press the up or down arrow buttons to navigate through each of the display windows. To exit the IPC dealer test mode, press and hold the OK button for 5-8 seconds or place the ignition in OFF. Each down arrow button press advances the viewing window to the next set of items. IPC Display Description Engineering Test Mode Use Right Up/Down to scroll screens Initial entry display into the dealer test mode. ANALOG GAUGE TEST Carries out the gauge sweep of the analog gauges. When the sweep (zero to maximum then return to zero) is complete, the actual data is displayed. TELLTALE AND COLOR TEST Illuminates all cluster microprocessor controlled LED telltales or indicators. Also displays a color palette of boxes below the title. PartNo: xxxx-xx Core: xxxx-xx Cal#1: xxxx-xx ECU S/W: xxxx-xx Displays the IPC part number information. Man Date: xxxxxx B&A Config Bytes xx xx xx xx xx xx xx xx xx xx Displays the manufacturing information. Date in the format of YYMMDD. B&A configuration bytes DTC: HIST CURR xxxxxx x x xxxxxx x x Displays all of the Diagnostic Trouble Codes (DTCs) set (history and current Diagnostic Trouble Codes [DTCs]). An X in the HIST or CURR column means the DTC is active. Three Diagnostic Trouble Codes (DTCs) display on each screen. If more Diagnostic Trouble Codes (DTCs) are present, there will be additional screens listing them. If there are no Diagnostic Trouble Codes (DTCs) in history or current, the display will only be the title row. Vehicle Speed: xxx.x km/h xxx.x MPH Tach: xxxx RPM NOTE: These are the filtered values used to drive the gauge positions, not the actual positions. Displays the digital representation of the speedometer gauge in mph and km/h. Inst Fuel: xxxx FLPM: xxxx.xx Displays the instant fuel level and filtered fuel level in percent. This is used for a single sender fuel level input. Inst Fuel1: xxxx FLPM: xxxx.xx Displays the instant fuel level and filtered fuel level in percent. This is used for the fuel pump assembly input on a dual sender fuel tank configuration. Inst Fuel2: xxxx FLPM: xxxx.xx Displays the instant fuel level and filtered fuel level in percent. This is used for the fuel level sensor input on a dual sender fuel tank configuration. DTE: Inst 01 Disp km xxx xxx xxx mi xxx xxx xxx Displays the values used for calculating the DTE function. RAFE RAFE_01 xxx.x xxx.x 1/100km xxx.x xxx.x MPG xxx.x xxx.x km/l Displays the running average fuel economy. The values are derived from the DTE function. State Val #ofVS Szero: xxxx xxxx Off: xxxx xxxx On: xxxx xxxx Displays the key ON initialization, key OFF reference, and zero speed reference fuel level values in fuel level for a single sender fuel level input. State Val #ofVS Szero1: xxxx xxxx Off: xxxx xxxx On: xxxx xxxx Displays the key ON initialization, key OFF reference, and zero speed reference fuel level values in fuel level for the fuel pump assembly input on a dual sender fuel tank configuration. State Val #ofVS Szero2: xxxx xxxx Off: xxxx xxxx On: xxxx xxxx Displays the key ON initialization, key OFF reference, and zero speed reference fuel level values in fuel level for the fuel level sensor input on a dual sender fuel tank configuration. Coolant Temp (°C): xxx Displays the digital representation of the coolant temperature gauge indication in degrees Celsius. Odo cnts: xx Trip A: xxxxx.x km Trip A: xxxxx.x mi Displays the values from the odometer count signal and the trip A statistics. Odo cnts: xx Trip B: xxxxx.x km Trip B: xxxxx.x mi Displays the values from the odometer count signal and the trip B statistics. Fuel cnts: xxx Fuel A: xxxxx.x l Fuel A: xxxxx.x g Displays the values of the fuel flow display signal from the PCM and the approximate fuel used for the trip stats A. Fuel cnts: xxx Fuel B: xxxxx.x l Fuel B: xxxxx.x g Displays the values of the fuel flow display signal from the PCM and the approximate fuel used for the trip stats B. Battery: xx.xV Compass: xx Last Chime: xx Displays the current battery level. Displays the compass direction. Displays the number of the last chime sounded. Dim Step: xx Dim Gauge: xxxxx Dim Pointer: xxxxx Displays the first screen of dimming information. Dim step is the dimming level. Dim gauge is the internal illumination number for the gauge backlighting (1 to 10,000). Dim pointer is the internal illumination number for the gauge pointer backlighting (1 to 10,000). Dim Step: xx Dim PRNDL: xxxxx Dim Display: xxxxx Displays the second screen of dimming information. Dim step is dimming level. Dim PRNDL is the internal illumination number for PRNDL backlighting (1 to 10,000). Dim display is the internal illumination number for the display backlighting (1 to 10,000). PDS: x LWS: x Park detect switch (0 = open/not park, 1 = closed/park). Engineering Test Mode Use Right Up/Down to scroll screens Repeats the test display cycle. Please report back here any DTCs that are revealed by a code scanner or Dealer Test Mode, and we'll provide additional guidance. Relevant procedures and wiring & connector information is attached below as PDF documents. Good luck! Instrument Panel Cluster (IPC) - System Operation and Component Description - 2016 Edge Workshop Manual.pdf ENGINE COOLANT TEMPERATURE (ECT) SENSOR - Connector C1016 - Pin-Circuit Details - 2016 Edge.pdf ENGINE COOLANT TEMPERATURE (ECT) SENSOR - Connector C1016 - Location - 2016 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C1551E - Pin-Circuit Details - 2016 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C1551E -Location - 2016 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Removal and Installation - FOR LOCATION ILLUSTRATIONS - 2016 Edge Workshop Manual.pdf Engine Coolant Temperature (ECT) Sensor to Powertrain Control Module (PCM) Wiring Diagram - 2016 Edge.pdf- 4 replies

-

- 3

-

-

- engine coolant over temp

- 2.7 ecoboost

-

(and 2 more)

Tagged with:

-

Welcome to the Forum @BrandonS! I suspect the Edge's erratic symptoms may be the result of a failing or failed battery, based upon unexpected behavior of Instrument Cluster warning lights and its Message Center, as shown in the 17-seconds-long stuck-on washer pump video... Have the Edge's battery tested at a reputable battery seller or neighborhood auto parts store. If the battery tests good, then ask if they can scan the Edge's electronic modules for Diagnostic Trouble Codes (DTCs), and report any observed DTCs back here, then we'll provide additional guidance. 2010 Edge Workshop Manual sections relating to Instrument Cluster and Message Center behavior are attached below as PDF documents... Good luck! Instrument Cluster - 2010 Edge Workshop Manual.pdf Instrument Cluster Prove-Out Chart - 2010 Edge Workshop Manual.pdf Information And Message Center - 2010 Edge Workshop Manual.pdf

-

@BMWR1200c: The 2020 Edge Workshop Manual procedures are identical to the above-attached 2022-2024 Edge Workshop Manual procedures. Wheel lug nut torque is contained in the attached PDF document... Good luck! Wheel and Tire - Removal and Installation - 2020 Edge Workshop Manual.pdf

-

From the 2022-2024 Edge Workshop Manual, and attached below as PDF documents... Good luck! On both sides. Remove the push nuts, release the tabs and remove the rear reflector. Rear Lamp Assembly - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf Rear Bumper Cover - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf Rear Bumper Cover - Disassembly and Assembly - 2022-2024 Edge Workshop Manual.pdf