Haz

Edge Member-

Posts

1,350 -

Joined

-

Last visited

-

Days Won

357

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

Welcome to the Forum @Harleyflt04! From the 2013 Edge Wiring Manual... Good luck! POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Pin-Circuit Details - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connectors C175B, C175E, C175T Location in Bulkhead - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175E Pin-Circuit Details - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175T Pin-Circuit Details - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #1 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #2 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #3 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #4 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #5 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #6 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #7 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #8 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #9 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #10 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #11 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Electronic Engine Controls #12 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Transmission Controls #1 - 3.5L TiVCT -2013 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Transmission Controls #2 - 3.5L TiVCT -2013 Edge.pdf

-

SSM 52419 Various Vehicles - 1.5L/2.0L/2.3L - Misfire With Diagnostic Trouble Code (DTC) P0301, P0302, P0303, And/Or P0304 Stored In The PCM Some 2023-2024 Escape/Corsair vehicles equipped with a 1.5L or 2.0L EcoBoost engine, 2024 Mustang vehicles equipped with a 2.3L EcoBoost engine, and 2024 Nautilus vehicles may exhibit an engine misfire condition with diagnostic trouble codes (DTC) P0301, P0302, P0303 and/or P0304 set in the powertrain control module (PCM). If the codes are stored in the PCM, remove and inspect the condition of all the spark plugs. If any spark plugs appear to be damaged, use a borescope to inspect the condition of the cylinder walls. If the cylinder walls are scored/scraped/damaged, replace the long block engine assembly (6006) to resolve this condition. If the cylinder walls are not scored/scraped/damaged, replace the damaged spark plug(s) and advise the customer that engineering is investigating this issue. Monitor OASIS for additional information and schedule service appointments for customers once the repair becomes available.

-

Two terminal versus three terminal oil pressure switch/ sensor

Haz replied to JayMarks40's topic in 2015 Edge & MKX

DIAGNOSTIC PINPOINT TEST AO The Low Oil Pressure RTT Warning Indicator Is Never Or Always On (2.0L EcoBoost) Refer to Wiring Diagrams for schematic and connector information. Normal Operation and Fault Conditions See Low Oil Pressure RTT Warning Indicator. If the engine rpm data or oil pressure warning message is missing less than 5 seconds, the IPC defaults the low oil pressure warning RTT indicator to the last state (on or off), based upon the last message received. If the engine rpm data or oil pressure warning message is missing for 5 seconds or longer, the IPC defaults the low oil pressure warning RTT indicator on. DTC Chart - PCM DTC Description Fault Trigger Conditions P0521 Engine Oil Pressure Sensor/Switch "A" Circuit Range/Performance Sets in the PCM when the PCM detects signal variation outside of the module parameters on the hardwired input from the oil pressure switch. P0522 Engine Oil Pressure Sensor/Switch "A" Circuit Low Sets in the PCM when the PCM detects a short to ground on the hardwired input from the oil pressure switch. P0523 Engine Oil Pressure Sensor/Switch "A" Circuit High Sets in the PCM when the PCM detects an open on the hardwired input from the oil pressure switch. P0524 Engine Oil Pressure Too Low Sets in the PCM when the PCM detects low oil pressure. Possible Sources Wiring, terminals or connectors Tachometer concern Message center concern Engine oil pressure switch Engine oil pressure concern GWM concern PCM concern IPC Visual Inspection and Diagnostic Pre-checks Inspect the: engine for noise or other symptom indicating a base engine or low engine oil pressure concern. engine oil pressure switch for signs of external damage. engine oil pressure switch connector for signs of corrosion harness for damage indicating an open or short to ground. PINPOINT TEST AO: THE LOW OIL PRESSURE RTT (RECONFIGURABLE TELLTALE) WARNING INDICATOR IS NEVER OR ALWAYS ON (2.0L EcoBoost ENGINE) AO1 CHECK THE MESSAGE CENTER OPERATION Ignition ON. Close all doors, the hood and the liftgate. Clear all message center warnings by pressing the OK button for each warning present. Monitor the door ajar RTT warning indicator. Open the driver door. Clear the message center popup warning. Monitor the door ajar RTT warning indicator. Is the door ajar RTT warning indicator off with the door closed, and on with the door open? Yes GO to AO2 No VIN required to access Guided Routine (IPC) AO2 CHECK THE GWM (GATEWAY MODULE A) DIAGNOSTIC TROUBLE CODES (DTCS) Using a diagnostic scan tool, check the GWM Continuous Memory Diagnostic Trouble Codes (CMDTCs). Are any Diagnostic Trouble Codes (DTCs) recorded? Yes REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing). No GO to AO3 AO3 CHECK THE TACHOMETER OPERATION Start the engine. NOTE: For the optional dual 4.2" message center display IPC , make sure the IPC is set to display the tachometer. The IPC and message center navigation can be found in the Owner's Literature Verify the tachometer operates. Does the tachometer operate? Yes GO to AO4 No For the optional IPC , GO to Pinpoint Test B For the base IPC , GO to Pinpoint Test H AO4 PERFORM THE IPC (INSTRUMENT PANEL CLUSTER) SELF-TEST Using a diagnostic scan tool, perform the IPC self-test. Are any Diagnostic Trouble Codes (DTCs) recorded? Yes REFER to DTC Chart: IPC in this section. No GO to AO5 AO5 CHECK THE OIL PRESSURE Test the engine for low oil pressure. Was a low oil pressure concern detected? Yes REPAIR the low oil pressure concern. REFER to: Engine (303-00 Engine System - General Information, Diagnosis and Testing). No GO to AO6 AO6 CHECK FOR VOLTAGE AT THE OIL PRESSURE SWITCH Ignition OFF. Disconnect Engine Oil Pressure Switch C1657 (2.0L). Ignition ON. Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1657 Pin 3 C1657 Pin 2 Is the voltage approximately 5 volts? Yes GO to AO7 No GO to AO10 AO7 CHECK THE OIL PRESSURE SENSOR SIGNAL CIRCUIT FOR A SHORT TO VOLTAGE Ignition OFF. Disconnect PCM C1381B (2.0L Engine). Ignition ON. Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1381B Pin 70 Ground Is any voltage present? Yes REPAIR the circuit. No GO to AO8 AO8 CHECK THE OIL PRESSURE SENSOR SIGNAL CIRCUIT FOR AN OPEN Ignition OFF. Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1381B Pin 70 C1657 Pin 1 Is the resistance less than 3 ohms? Yes GO to AO9 No REPAIR the circuit. AO9 CHECK THE OIL PRESSURE SENSOR SIGNAL CIRCUIT FOR A SHORT TO GROUND Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1657 Pin 1 Ground Is the resistance greater than 10,000 ohms? Yes GO to AO14 No REPAIR the circuit. AO10 CHECK THE OIL PRESSURE SENSOR VREF CIRCUIT FOR A SHORT TO VOLTAGE Ignition OFF. Disconnect PCM C1381B (2.0L Engine). Ignition ON. Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1657 Pin 3 Ground Is any voltage present? Yes REPAIR the circuit. No GO to AO11 AO11 CHECK THE OIL PRESSURE SENSOR VREF CIRCUIT FOR AN OPEN Ignition OFF. Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1657 Pin 3 C1381E Pin 6 Is the resistance less than 3 ohms? Yes GO to AO12 No REPAIR the circuit. AO12 CHECK THE OIL PRESSURE SENSOR VREF CIRCUIT FOR A SHORT TO GROUND Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1657 Pin 3 Ground Is the resistance greater than 10,000 ohms? Yes GO to AO13 No REPAIR the circuit. AO13 CHECK THE OIL PRESSURE SENSOR RETURN CIRCUIT FOR AN OPEN Measure: 2.0L Engine Positive Lead Measurement / Action Negative Lead C1657 Pin 2 C1381E Pin 20 Is the resistance less than 3 ohms? Yes INSTALL a new engine oil pressure sensor. REFER to: Engine Oil Pressure (EOP) Sensor (303-14A Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) – MI4, Removal and Installation). CLEAR the Diagnostic Trouble Codes (DTCs). TEST the system for normal operation. If the oil pressure RTT is still never or always on, GO to AO14 No REPAIR the circuit. AO14 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION Ignition OFF. Disconnect and inspect the PCM and all related in-line connectors. Repair: corrosion (install new connector or terminals - clean module pins) damaged or bent pins - install new terminals/pins pushed-out pins - install new pins as necessary Reconnect the PCM and all related in-line connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present Is the concern still present? Yes CHECK On-Line Automotive Service Information System (OASIS) for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new PCM. Refer to the appropriate Removal and Installation procedure in Section 303-14. No The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause of any connector or pin issues. Diagnostic Pinpoint Test AO Supporting Documents Engine Oil Pressure (EOP) Sensor - Wiring Diagram - 2.0L EcoBoost - 2015 Edge.pdfPOWERTRAIN CONTROL MODULE (PCM) - Connector C1381B Details - 2.0L EcoBoost - 2015 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C1381B Location - 2.0L EcoBoost - 2015 Edge.pdf Oil Pressure Control Solenoid - Wiring Diagram - 2.0L EcoBoost - 2015 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C1381E Details - 2.0L EcoBoost - 2015 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C1381E Location - 2.0L EcoBoost - 2015 Edge.pdf Powertrain Control Module (PCM) - Removal and Installation - 2.0L EcoBoost - 2015 Edge Workshop Manual.pdf Good luck! -

Two terminal versus three terminal oil pressure switch/ sensor

Haz replied to JayMarks40's topic in 2015 Edge & MKX

Welcome to the Forum, @JayMarks40 ! From the 2015 Edge Workshop Manual... Engine Overview - 2.0L EcoBoost - 2015 Edge Workshop Manual.pdf Engine Specifications - 2.0L EcoBoost - 2015 Edge Workshop Manual.pdf Engine Oil Pressure (EOP) Sensor - Removal and Installation - 2.0L EcoBoost - 2015 Edge Workshop Manual.pdf Engine Oil Pressure (EOP) Sensor - Connector C1657 Location - 2.0L EcoBoost - 2015 Edge.pdf Engine Oil Pressure (EOP) Sensor - Connector C1657 Details - 2.0L EcoBoost - 2015 Edge.pdf Oil Pressure Control Solenoid - Removal and Installation - 2.0L EcoBoost - 2015 Edge Workshop Manual.pdf Oil Pressure Control Solenoid - Connector C1924 Location - 2.0L EcoBoost - 2015 Edge.pdf Oil Pressure Control Solenoid - Connector C1924 Details - 2.0L EcoBoost - 2015 Edge.pdf Good luck! -

From Unifor's website... Unifor extremely disappointed in Ford Motor Company decision to delay Oakville transition APRIL 4, 2024 TORONTO—Unifor calls on Ford Motor Company to consider all possible options to mitigate the negative impact on workers following the announced substantial delay in the launch of EV production at the Oakville Assembly Plant. “Unifor is extremely disappointed by the company’s decision. Our members have done nothing but build best-in-class vehicles for Ford Motor Company and they deserve certainty in the company’s future production plans,” said Unifor National President Lana Payne. “I want to be very clear here. Our members can be assured that we will push the company to explore every single possible opportunity to lessen the impact of this decision on them and their families.” Ford has announced that while the retooling of Oakville Assembly Plant will commence this Spring as planned, the company is delaying the launch of EV production from 2025 to 2027. Unifor was informed of the revised timeline during a meeting with Ford executives earlier this week. Unifor represents more than 5,600 Ford Canada workers, including 3,200 Local 707 members employed at the Oakville Assembly Plant. In 2020, Ford announced an historic $1.8 billion investment to retool the Oakville Plant for EV and battery pack production. In 2023 contract negotiations with Ford, Unifor negotiated innovative income and benefit transition supports, covering members at the Oakville plant for what was originally forecasted to be an eight-month retooling period. Negotiations included a provision that should the retooling period extend beyond eight months the company and the union will meet to discuss extending this arrangement. “There will be unexpected setbacks in the transition to EV, but we fully expect Ford to investigate every available option to support our Oakville members. It is unacceptable, after 120 years of operation in this country, that Ford does not plan to build a single vehicle in Canada for years on end,” said Local 707 Oakville Assembly Complex Chairperson Marc Brennan. Given the magnitude of the delay Unifor has requested a meeting with Ford to be held as soon as possible to discuss job and income security measures for workers. Ford Edge production at Oakville Assembly is scheduled to end in approximately one month. “This is a significant setback and while the first stages of retooling are still on track and we remain committed to securing an EV future for the workers of Oakville, the immediate challenges faced by our members will be front and centre in our discussions with the company,” Payne added. Unifor is Canada's largest union in the private sector and represents 315,000 workers in every major area of the economy. The union advocates for all working people and their rights, fights for equality and social justice in Canada and abroad, and strives to create progressive change for a better future.

-

These recent discussions may be helpful to you... Edge ST with performance brakes spare tire originated by @taurussvt Performance brake and tire package originated by @STBEAST Good luck!

- 1 reply

-

- 1

-

-

SYNC 3 navigation offers maps for North Africa and South Africa, however SYNC 2 navigation may not be available. You might try telephoning the South Africa Ford Customer Relationship Center (CRC) , or e-mail the below CRC that best describes your region of Africa... South Africa 0860011022 fordcrc2@ford.com Sub-Saharan Africa ssacrc@ford.com North Africa nafcrc@ford.com Good luck!

-

For your subject matter research and Model Year comparisons... Instrument Panel Cluster (IPC) -Description and Operation - 2011 Edge-MKX Workshop Manual.pdf INSTRUMENT PANEL CLUSTER (IPC) - Connector C220 Pin-to-Circuit Details - 2011 Edge-MKX.pdf Instrument Panel Cluster (IPC) - Removal and Installation - 2011 MKX Workshop Manual.pdf Instrument Panel Cluster - Removal and Installation - Enhanced Image - 2011 Edge.pdf Instrument Panel Cluster - Removal and Installation - Enhanced Image - 2011 MKX.pdf Instrument Panel Cluster (IPC) - As-Built Configuration - 2011 MKX.pdf Instrument Panel Cluster (IPC) - Overview - 2016 MKX Workshop Manual.pdf Instrument Panel Cluster (IPC) - System Operation and Component Description - 2016 MKX Workshop Manual.pdf INSTRUMENT PANEL CLUSTER (IPC) - Connector C220 Pin-to-Circuit Details - 2016 MKX.pdf Instrument Panel Cluster (IPC) - Removal and Installation - 2016 MKX Workshop Manual.pdf Instrument Panel Cluster (IPC) - As-Built Configuration - 2016 MKX Select.pdf Instrument Panel Cluster (IPC) - Overview - 2022-2023 Nautilus Workshop Manual.pdf Instrument Panel Cluster (IPC) - System Operation and Component Description - 2022-2023 Nautilus Workshop Manual.pdf INSTRUMENT PANEL CLUSTER (IPC) - Connector C220 Pin-to-Circuit Details - 2022-2023 Nautilus.pdf Instrument Panel Cluster (IPC) - As-Built Configuration - 2022 Nautilus Standard.pdf Good luck!

-

SSM 52402 - 2024 Nautilus - Keyless Entry Keypad Illumination On 2024 Nautilus vehicles, the keyless entry keypad will only illuminate if the unlock button on the keyfob is pressed or if the keypad itself is touched. The keypad will not illuminate during approach detection or from any other inputs. Do not attempt repairs or submit a claim for this normal condition.

-

Wireless Accessory Charging Module (WACM) documents attached below... Wireless Accessory Charging Module (WACM) - Overview - 2020 Edge Workshop Manual.pdf Wireless Accessory Charging Module (WACM) - System Operation and Component Description - 2020 Edge Workshop Manual.pdf Wireless Accessory Charging Module (WACM) - Removal and Installation - 2020 Edge Workshop Manual.pdf Wireless Accessory Charging Module (WACM) - Diagnosis and Testing - 2020 Edge Workshop Manual.pdf Wireless Accessory Charging Module (WACM) - Grounds - Wiring Diagram - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Power Distribution #1 - Wiring Diagram - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Power Distribution #2 - Wiring Diagram - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Module Communications #1 - Wiring Diagram - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Module Communications #2 - Wiring Diagram - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Wiring Diagram - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Connector C390 Details - 2020 Edge.pdf Wireless Accessory Charging Module (WACM) - Connector C390 Location - 2020 Edge.pdf Good luck!

-

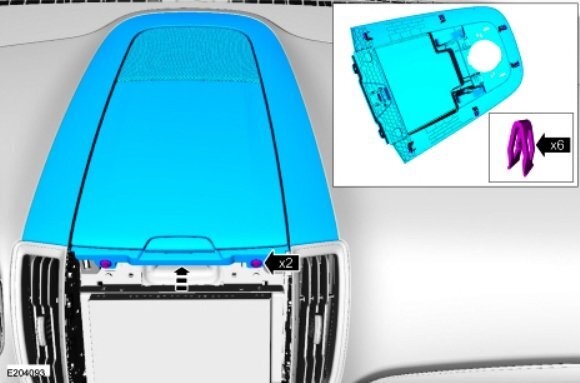

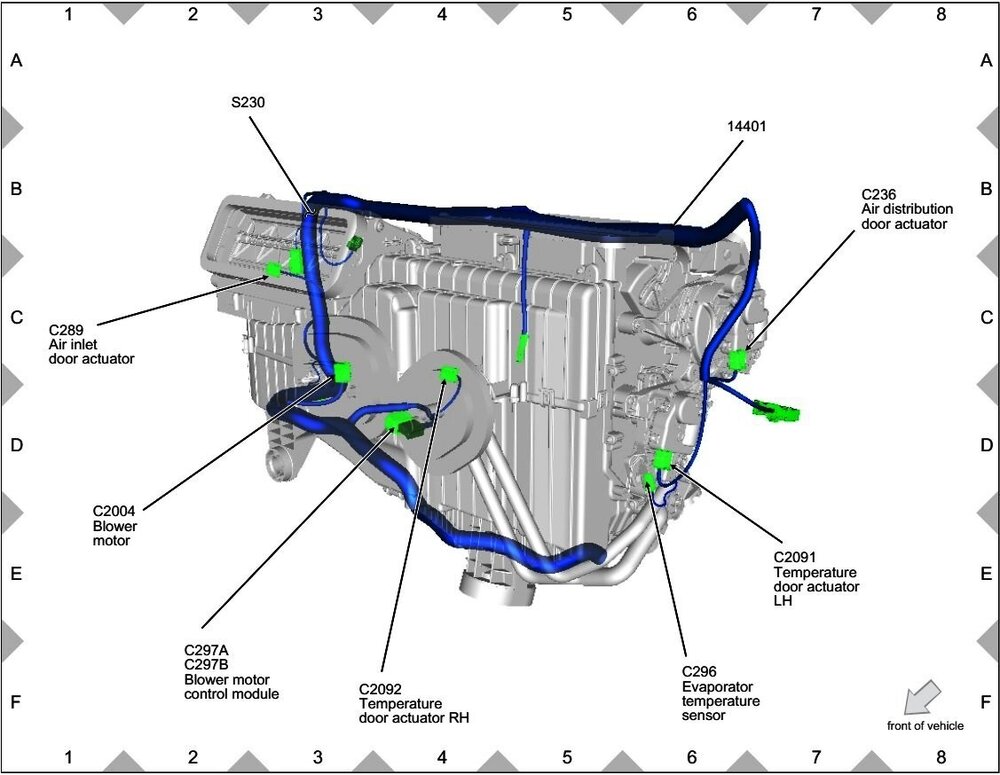

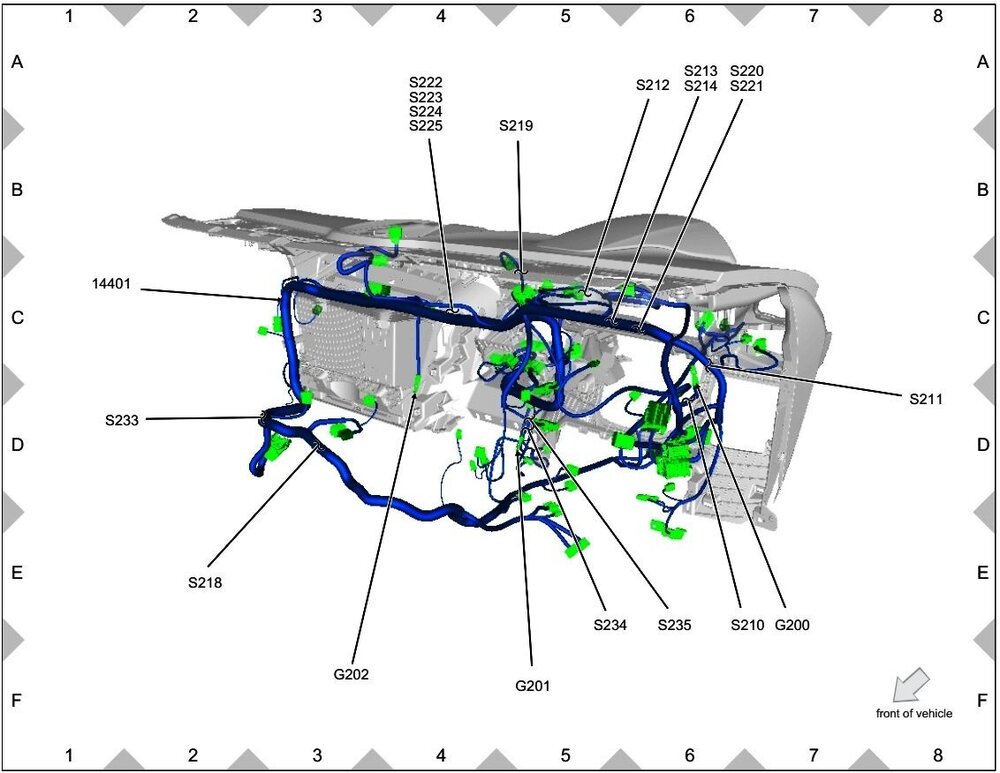

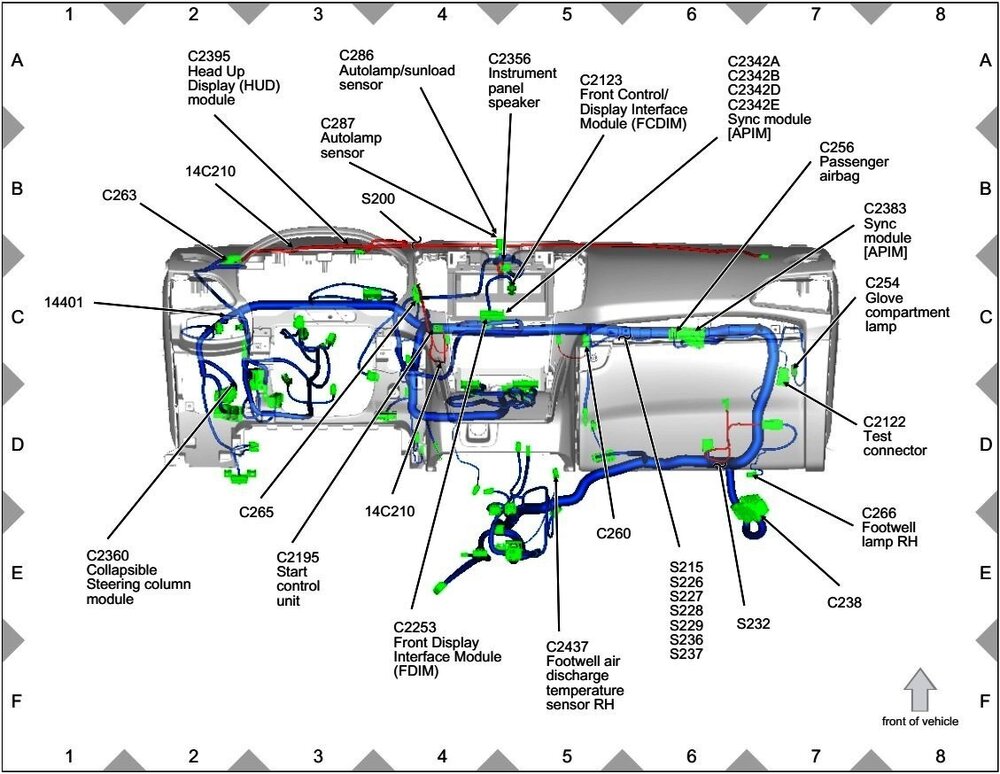

As the Workshop Manual image shows, the removable Upper Instrument Panel Storage Bin is retained by six clips and two screws... The 2017 Edge Wiring Diagrams offer several views of Instrument Panel and Heater/Evaporator Core Housing harnesses... Clearances between the floor of the Upper Instrument Panel Storage Bin and the various wiring harnesses & Heater/Evaporator Core Housing are unclear. Removing the Storage Bin involves disassembling several trim pieces and center stack components using procedures described in the below-attached documents... Front Controls Interface Module (FCIM) - Removal and Installation - With Touchscreen - 2017 Edge Workshop Manual.pdf Front Controls Interface Module (FCIM) - Removal and Installation - Sony Audio System - 2017 Edge Workshop Manual.pdf Center Registers - Removal and Installation - 2017 Edge Workshop Manual.pdf Instrument Panel Storage Bin – Removal (Task-specific edited from 2017 Edge Workshop Manual resource).pdf Heater Core and Evaporator Core Housing (For Imagery) - Removal and Installation - 2017 Edge Workshop Manual.pdf Instrument Panel Wiring Diagram - Interior View - 2017 Edge.pdf Instrument Panel Wiring Diagram - From Firewall View - 2017 Edge.pdf Climate Control Housing and Wiring Diagram - Firewall View - 2017 Edge.pdf When faced with where to place a Galaxy CB radio in our previous MKX, I elected to mount the bracket on the driver's door panel storage bin... Outboard leg room was diminished a bit, but the radio's controls were visible & usable when driving, and being black-on-black, the radio wasn't obvious when looking in from outside the vehicle. Good luck!

-

SSM 52393 2024 Nautilus - Predelivery Removal Tips For Exterior Shipping Protection (RapGard) Some 2024 Nautilus vehicles may exhibit difficulty removing shipping door protectors or white RapGard during predelivery. This may be attributed to varied environmental conditions during transit from the assembly plant to the dealerships. If possible, bring the vehicle into the shop to warm up and stabilize to a room temperature closer to 20°C (68°F) or higher prior to removing the plastic coverings. Running the engine may help in warming the hood wrapping adhesive for easier removal. Also, reuse the white RapGard that was removed from the car to dab/remove any adhesive residue left behind. For general guidelines, refer to the Warranty and Policy Manual, Section 2.9.00 Storage of New Vehicles. It's worth noting that in recent years, other automotive manufacturers have experienced paint defects caused by water migration beneath RapGard protective film. While differences exist between manufacturers' RapGard application methods, paint formulations, and vehicle sheltering during transit, it may be prudent for prospective 2024 Nautilus buyers to inspect the vehicle's paint to ensure defects like those pictured in the below-attached Volkswagen Technical Service Bulletin are not present. Volkswagen TSB 00-19-01 - Paint Defect - Water Migration Under the RapGard - 01-30-2023.pdf

-

Fluttering Noise from Undercarriage and Dashboad Rattle

Haz replied to CCMAYES72's topic in Brakes, Chassis & Suspension

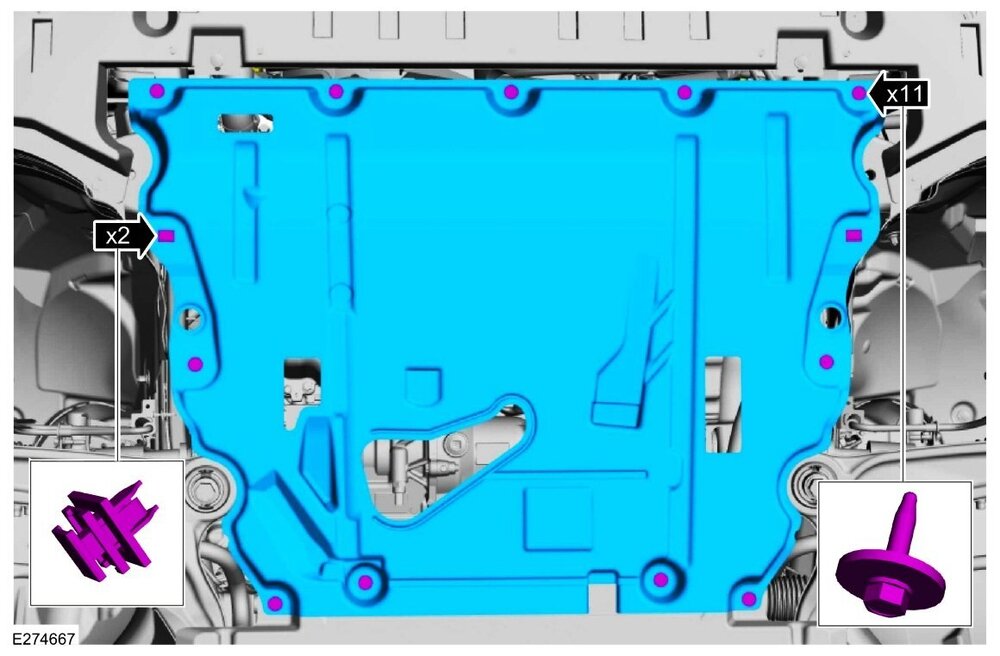

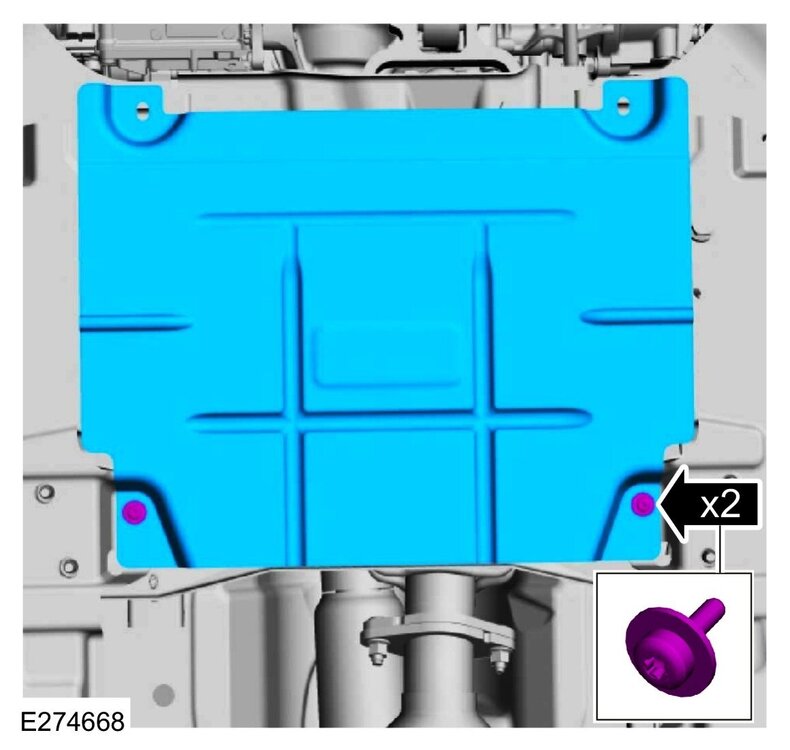

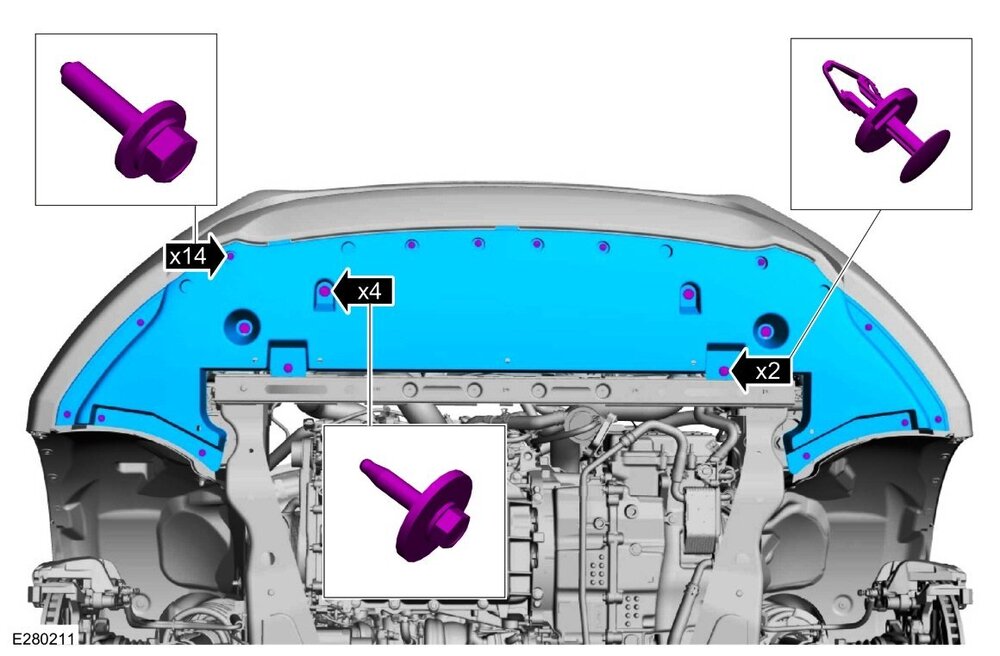

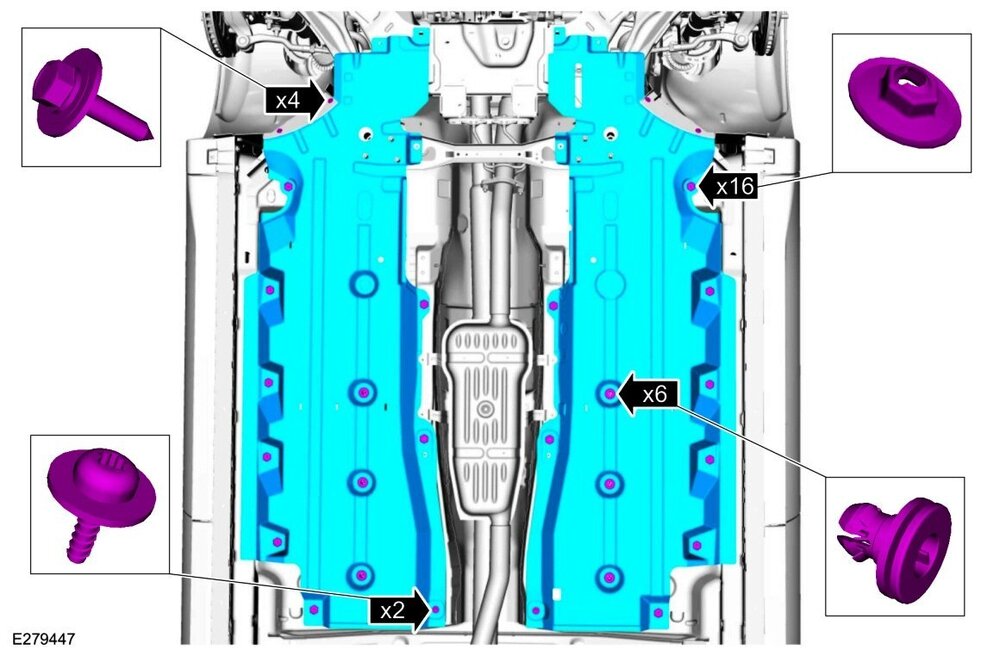

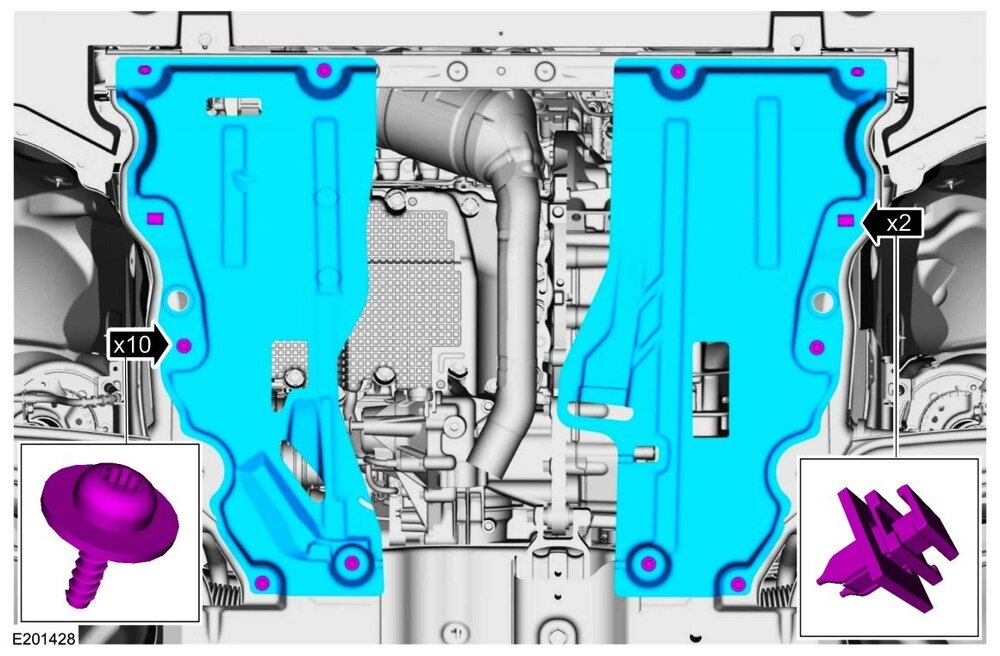

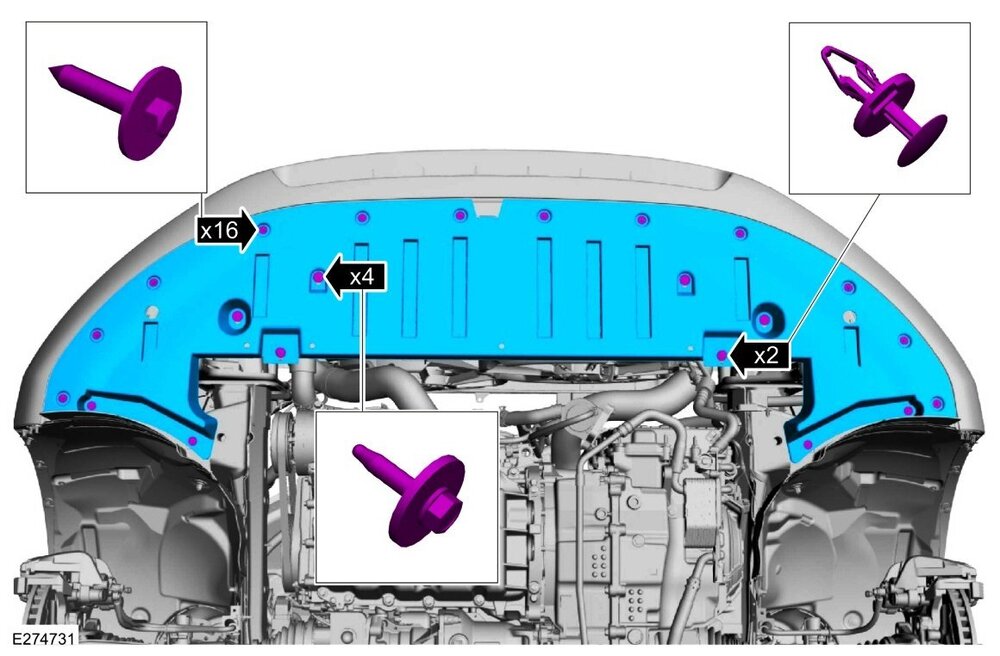

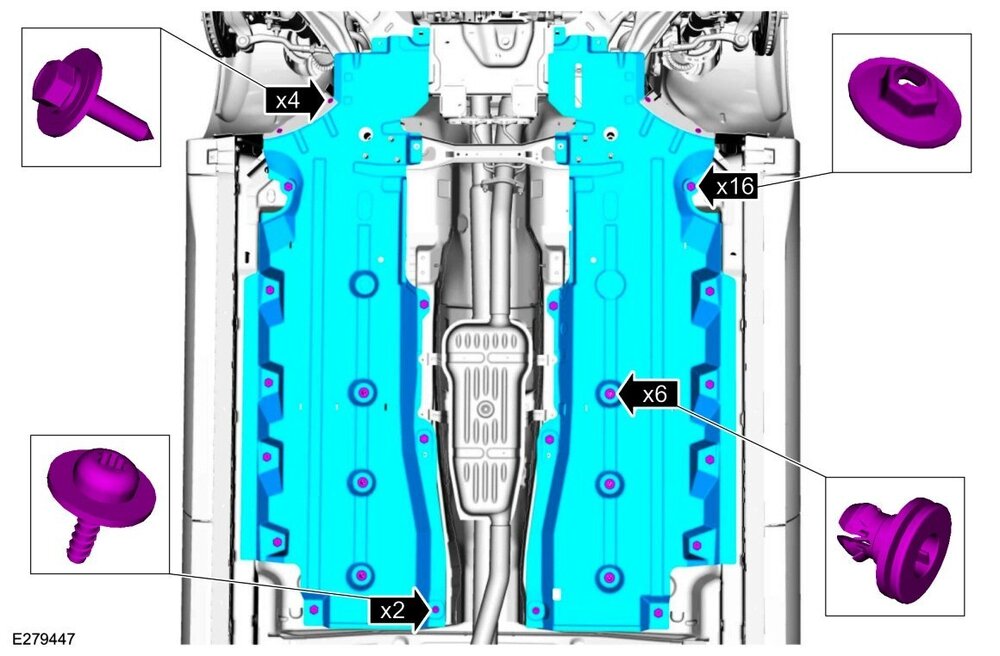

The following Underbody Shield images from the 2020 Edge Workshop Manual depict retainer types, quantities, and locations... 2.0L EcoBoost 2.7L EcoBoost PDF versions of these images are attached below... Underbody Shield Image #1 - 2.0 EcoBoost - 2020 Edge Workshop Manual.pdf Underbody Shield Image #2 - 2.0 EcoBoost - 2020 Edge Workshop Manual.pdf Underbody Shield Image #3 - 2.0 EcoBoost - 2020 Edge Workshop Manual.pdf Underbody Shield Image #4 - 2.0 EcoBoost - 2020 Edge Workshop Manual.pdf Underbody Shield Image #1 - 2.7 EcoBoost - 2020 Edge Workshop Manual.pdf Underbody Shield Image #2 - 2.7 EcoBoost - 2020 Edge Workshop Manual.pdf Underbody Shield Image #3 - 2.7 EcoBoost - 2020 Edge Workshop Manual.pdf Good luck!- 84 replies

-

- 1

-

-

- dash noise

- dash rattle

-

(and 4 more)

Tagged with:

-

According to the Cyanlabs As-Built Database, Ambient Lighting configurations in the Body Control Module (BCM) are... Ambient Light Sensor Present Configuration Ambient Light Sensor Type Configuration Ambient Lighting Configuration Ambient Delay Configuration Additionally, their database shows Ambient Lighting-related configurations in the APIM/SYNC Module of... Ambient Light (AL) Ambient Light Type (ALT) The below-attached 2016 Edge Workshop Manual section provides useful Ambient Lighting info, however, the Cyanlabs database presents As-Built values in granular detail. Interior Lighting - System Operation and Component Description - 2016 Edge Workshop Manual.pdf Good luck!

-

From the 2020 Edge Workshop Manual... Liftgate Trim Panel - Removal and Installation - 2020 Edge Workshop Manual.pdf Reversing Lamp - Removal and Installation - 2020 Edge Workshop Manual.pdf Liftgate Moulding - Removal and Installation - 2020 Edge Workshop Manual.pdf Good Luck!

-

Welcome to the Forum, @Anidog! Is it the Upper Instrument Panel Storage Bin that you are considering?... Or is it the Driver's Small Stowage Drawer that you are considering?... And finally, what is the Model Year and Trim level of your Edge? Good luck!

-

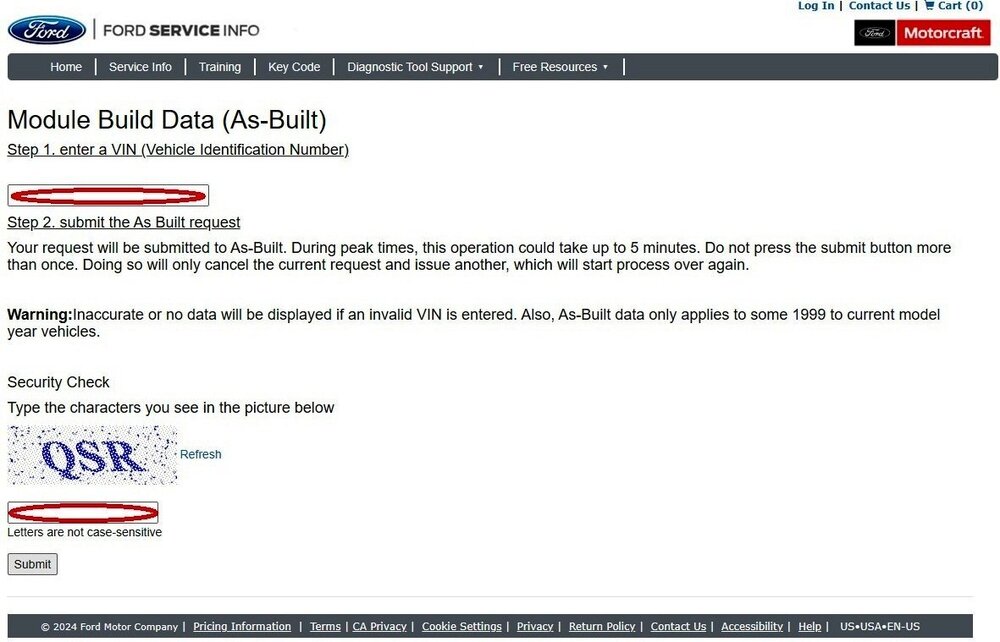

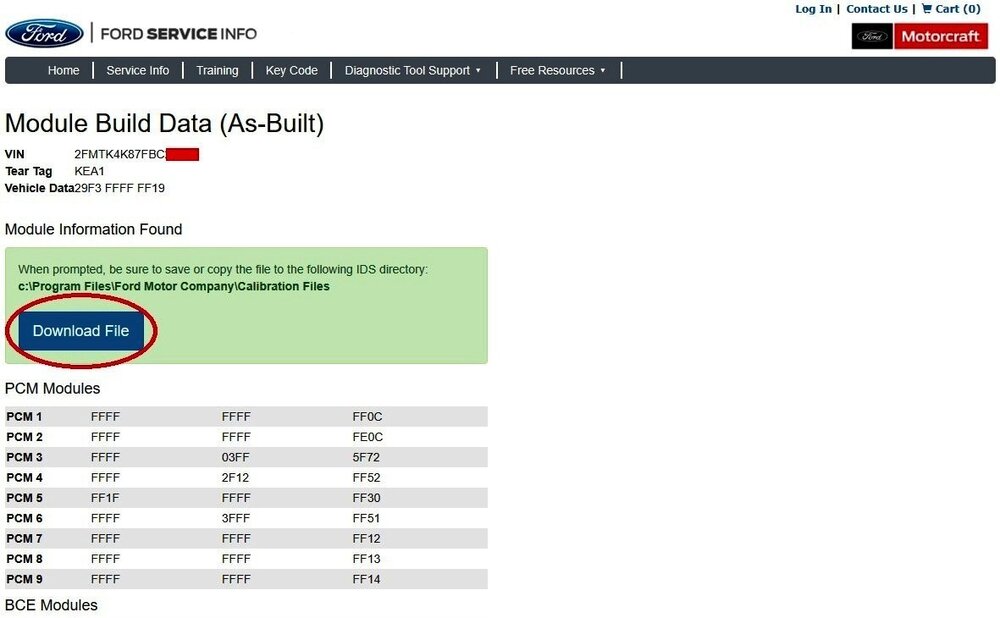

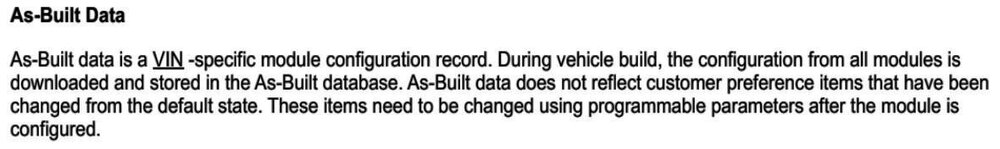

Welcome to the Forum, @jer2011! From the 2015 Edge Workshop Manual... If you installed a new module without saving its configuration data for transfer to the new module, you can obtain your Edge's As-Built all-module configuration record from the Ford Service Info site (link to opening page). Select your country and language from the drop-down lists and click the Submit button... Enter your Edge's VIN and the Security Check characters in their respective fields and click the Submit button... Your Edge's VIN-specific module configuration dataset will then be presented in hardcopy-printable text format (which your browser might also print to a PDF file), and the As-Built dataset can be downloaded as an .AB-format data file by clicking on the Download File button... The following chart includes 2015 Edge modules and their As-Built line-data addresses... (Placing your device cursor over underlined acronyms may yield their full-words description) Module Configuration and Parameter Chart Module Name Module Address Programmable Module Installation (PMI) Available Reprogram/Flash Capable Requires Adaptive Learning or Calibration Available Progammable Parameters APIM 7D0 Yes Yes No None ABS module 760 Yes Yes IVD initialization EPB apply and release Trailer sway assist ACM 727 Yes Yes No None BCM 726 Yes Yes Ambient lighting calibration Rear view camera calibration Remote start enable/disable Perimeter alarm Tire pressure CCM 764 Yes Yes Radar horizontal and vertical alignment calibration None DSP 783 Yes Yes No None DACMC (integrated with ACM ) 7D5 Yes Yes No None DC / DC converter control module (Voltage Quality Module [VQM]) 746 Yes Yes No None DDM 740 Yes Yes Windows initialization None DSM 744 Yes Yes No None SCME 776 Yes Yes No None FCDIM 7A5 Yes Yes No None FCIM 7A7 Yes Yes No None GWM 716 Yes Yes No None GPSM 701 Yes Yes No None HUD module 7B2 No No No None HSWM 714 Yes Yes No None IPC 720 Yes Yes No Daytime running lamps control function Remote start feature Remote start - climate settings Driver seat Passenger seat Rear defrost Steering wheel IPMA 706 Yes Yes Camera calibration None IPMB 7B1 Yes Yes Camera calibration None OCSM 765 No No OCSM re-zero None PAM (integrated with BCM ) 736 Yes Yes No None PSCM 730 Yes Yes No None PCM 7E0 Yes Yes Misfire Monitor Neutral Profile Correction procedure None PDM 741 Yes Yes Windows initialization None RTM 751 Yes Yes No None RGTM 775 Yes Yes No None RCM 737 Yes Yes No None SODL 7C4 Yes Yes No BLIS/CTA enable/disable Blockage enable/disable SODR 7C6 Yes Yes No BLIS/CTA enable/disable Blockage enable/disable SASM 797 Yes Yes Adaptive steering wheel angle sensor trim adjustment None SECM 7C5 Yes Yes Adaptive steering wheel angle sensor trim adjustment Actuator trim procedure None SCCM 724 Yes Yes No None TRM 791 Yes Yes No None Manually entering As-Built data values and saving them to the target module will require Forscan equipped with at least a free 2-month Extended License. Just in case it's your Edge's Rear Gate Trunk Module (RGTM) that you replaced, the following are download links to relevant Workshop Manual sections... Body Closure - System Operation and Component Description - 2015 Edge Workshop Manual.pdf Module Configuration - System Operation and Component Description- 2015 Edge Workshop Manual.pdf Power Liftgate Initialization - General Procedures - 2015 Edge Workshop Manual.pdf Rear Gate Trunk Module (RGTM) Fuse F10 - 2015 Edge Wiring Diagram.pdf Body Control Module - Fuse Location Illustration - 2015 Edge Wiring Diagram.pdf Body Control Module - Fuse-to-Circuit(s) Legend - 2015 Edge Wiring Diagram.pdf Rear Gate Trunk Module (RGTM) - Removal and Installation - 2015 Edge Workshop Manual.pdf Good luck!

-

From the 2007 Edge Workshop Manual... 3.5L Engine - Fuel Charging and Controls - Description and Operation Sequential Multi-Port Fuel Injection (SFI) The fuel charging and controls system consists of the: Throttle Body (TB) . fuel injectors. fuel rail. The fuel charging and controls system is: a Sequential Multi-Port Fuel Injection (SFI) system. Pulse Width Modulated (PWM) . Mass Air Flow (MAF) controlled. Fuel is metered into each intake port in a sequential firing order. Fuel injectors pulse to follow engine firing order, in accordance with engine demand, on a tuned intake manifold. The basic fuel requirement of the engine is determined from the data supplied to the PCM by the MAF sensor, which measures the amount of air being drawn into the engine. The various sensors detect any changes in the operating conditions and send signals to the PCM. This permits the PCM to control the opening duration (pulse width) of the fuel injectors and maintain optimum exhaust emission control and engine performance for all operating conditions. Throttle Body (TB) The TB : controls air supply to the intake manifold by electronically positioning the throttle plate. is not adjustable. Fuel Injectors The fuel injectors: are electronically operated by the PCM. atomize the fuel as the fuel is delivered. each have an internal solenoid that opens a needle valve, which injects fuel into the intake port in the cylinder head. are deposit resistant. Fuel Rail The fuel rail: receives fuel from the fuel supply tube. delivers fuel to the fuel injectors. The is no mention of an Idle Air Control (IAC) valve in the 2007 Edge Workshop Manual. There is no depiction of an IAC valve in the 2007 Edge Wiring Diagrams. There are no IAC-associated Diagnostic Trouble Codes (DTCs) included in the 2007 Edge Master DTC Chart. Good luck!

-

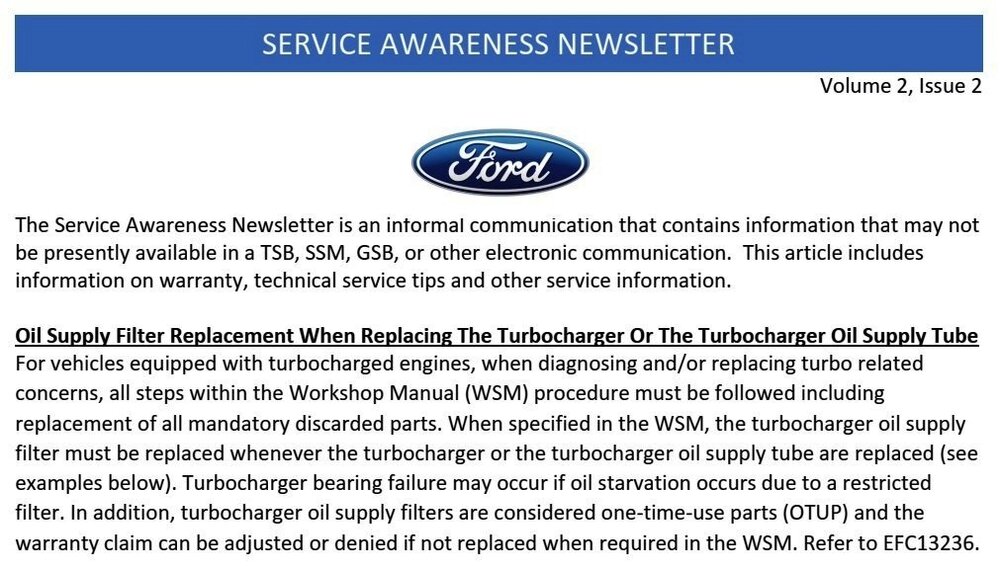

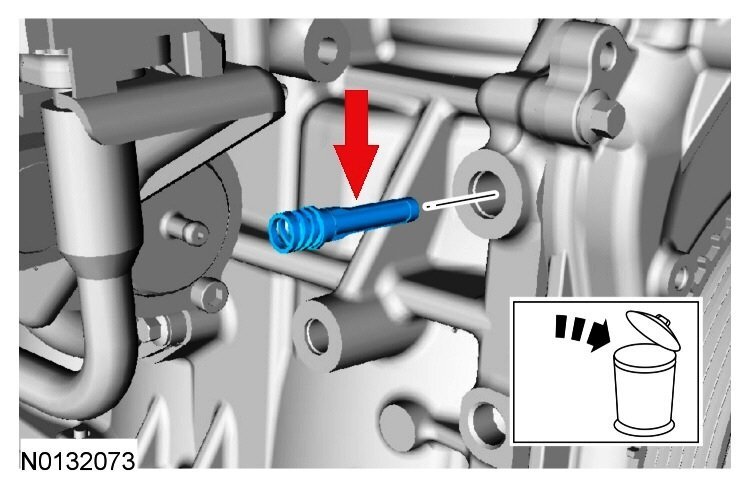

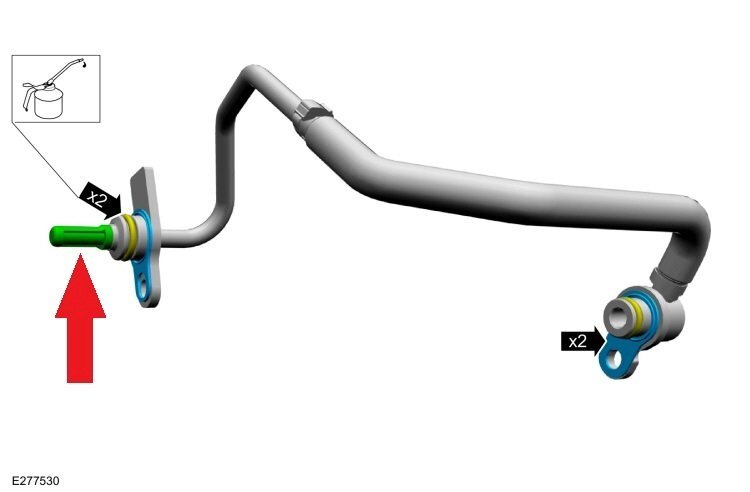

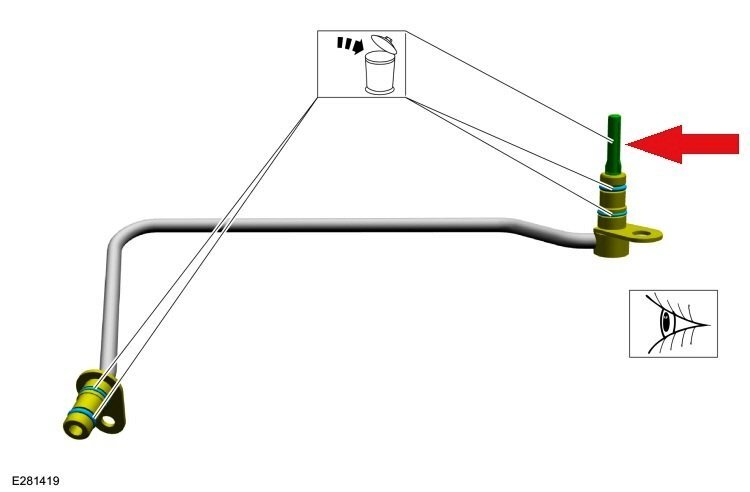

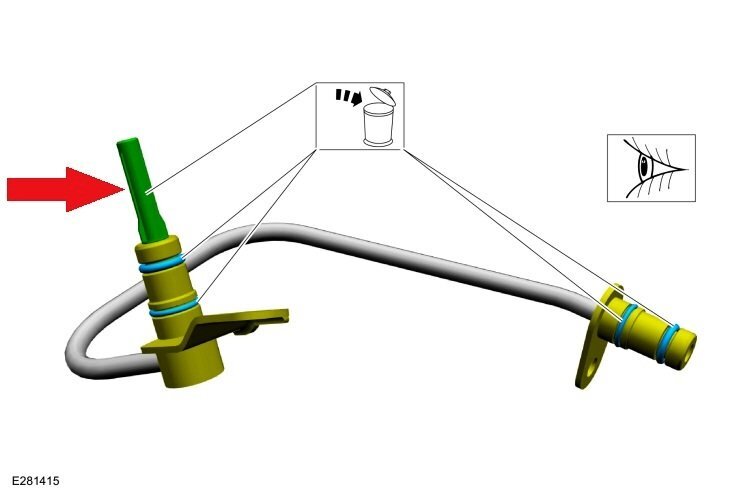

Great question! Essentially, this is Ford's reminder to Service technicians to install new filter/O-rings whenever the tube is removed and reinstalled, or when a new tube is installed if the original tube is damaged. Notable for me was the mention: "the warranty claim can be adjusted or denied if not replaced when required in the WSM " (Workshop Manual). Procedure from the Edge Workshop Manual (with emphasis added)... Upon removal NOTICE: Do not use a metal brush, damage to sealing area will result in leaks. Inspect the turbocharger tube and the sealing surfaces. Ensure that the retaining bracket is not bent, check for square-ness of the retaining bracket to the O-ring area. Use brake cleaner and a nylon brush to clean. Install new components as needed. Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B Remove and discard the turbocharger oil supply tube O-ring seals and the turbocharger oil supply tube oil filter. Upon installation Install the new turbocharger oil supply tube O-ring seals and the new turbocharger oil supply tube oil filter. Lubricate the new O-ring seals with clean engine oil. Refer to: Specifications (303-01B Engine - 2.7L EcoBoost (238kW/324PS), Specifications). NOTICE: Do not use a metal brush, damage to sealing area will result in leaks. NOTICE: When installing the turbocharger oil supply tube into the engine block, use care not to damage the new turbocharger oil supply tube oil filter. Carefully use a nylon brush to remove the old O-ring residue and use brake cleaner to rinse the O-ring residue out of the turbocharger tube to turbocharger O-ring bore and the turbocharger tube to engine O-ring bore. Inspect the area for deep scratches and gouges. Install new components as needed. Install the turbocharger oil supply tube, then install and tighten the turbocharger oil supply tube bolts. Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B Torque: 89 lb.in (10 Nm) Good luck!

-

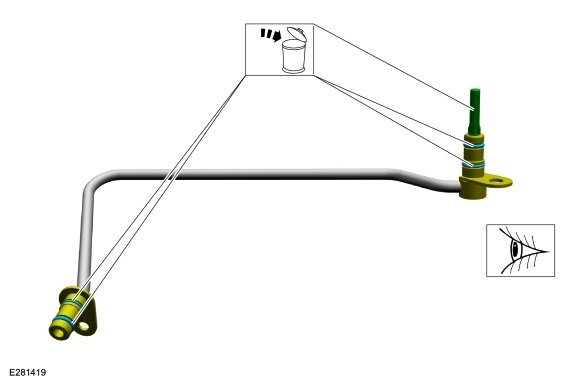

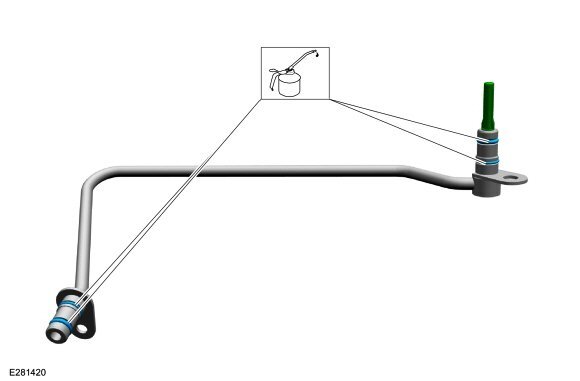

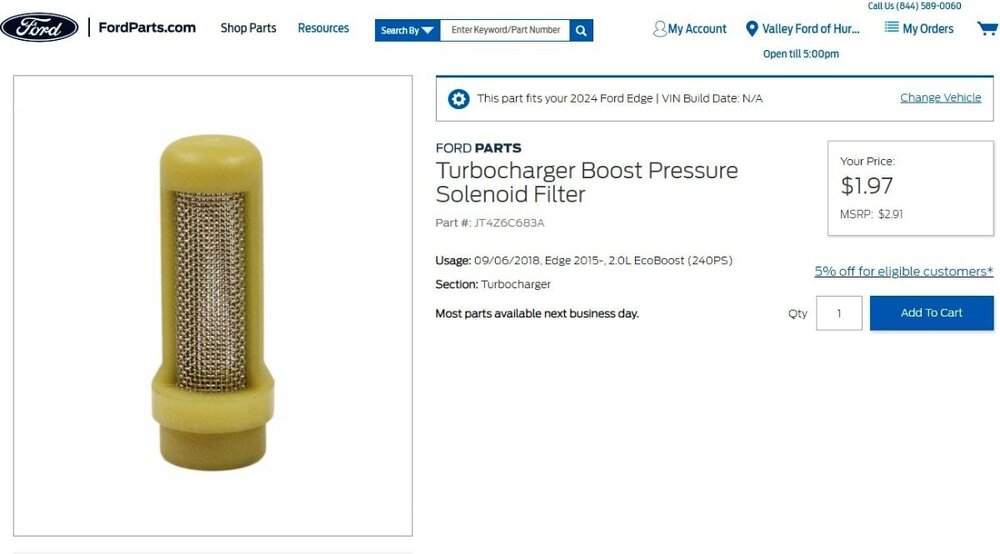

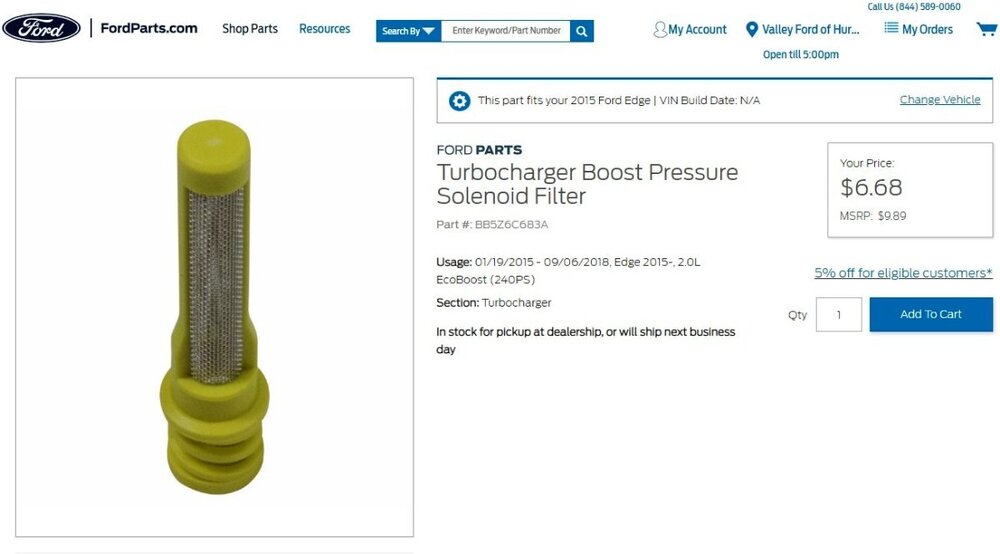

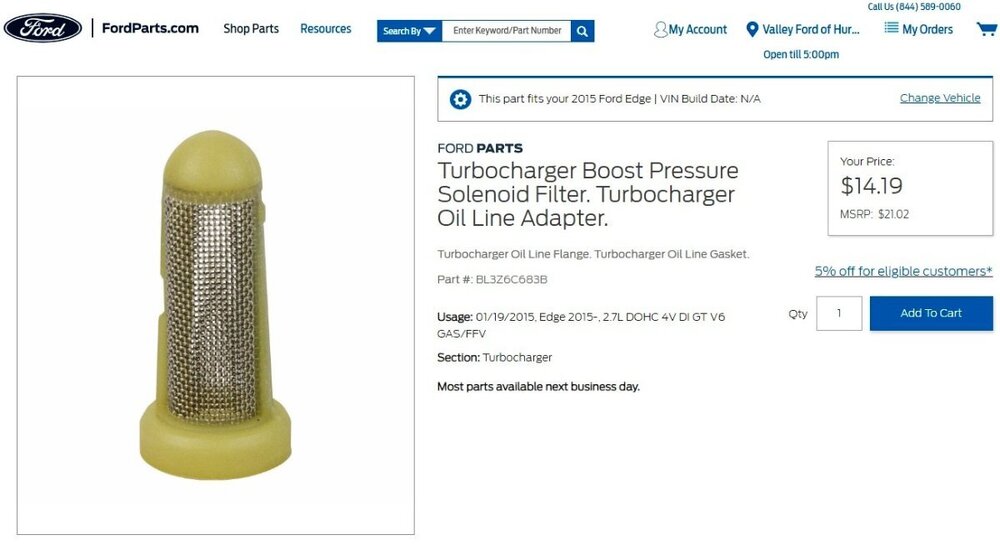

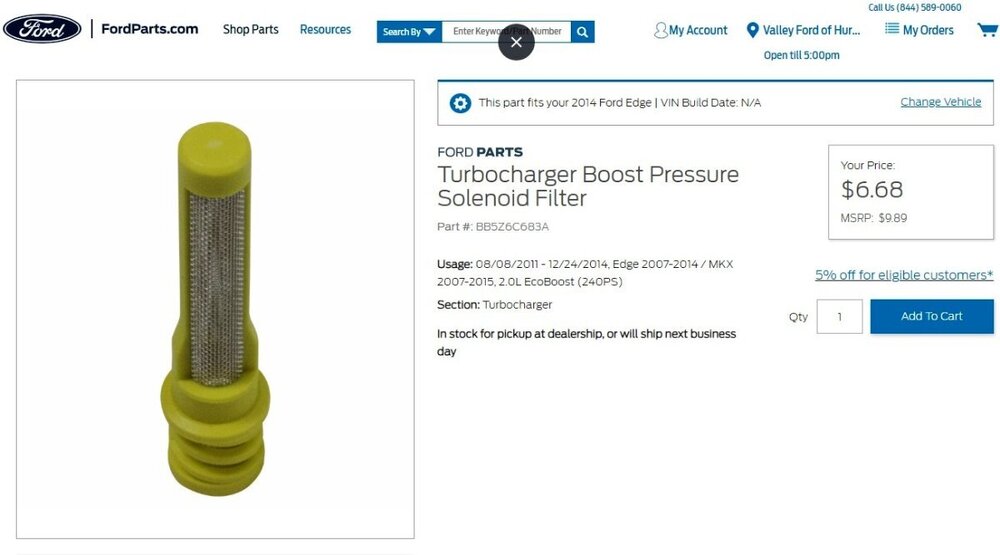

Supplemental images of Turbocharger Oil Supply Tubes from the Edge Workshop Manuals... EcoBoost 2.0L illustration - The filter is located on the Engine oil supply-side of the Tube. 2.0L EcoBoost Turbocharger Oil Supply Tube 2.7L EcoBoost Turbocharger Oil Supply Tube, Left Hand 2.7L EcoBoost Turbocharger Oil Supply Tube, Right Hand Example-listings of filters found on Ford's online parts-selling website... 2.0L EcoBoost - Two different part numbers and three listings are shown for various manufacturing dates, so searching by vehicle VIN would be advisable to ensure proper filter fitment. 2.7L EcoBoost - One listing found, though searching by vehicle VIN is always a good idea.

-

SSM 52378 2024 Nautilus - Driver Seat And Steering Column Not Moving To Easy Entry Position After Setting Up A Client Profile Some 2024 Nautilus vehicles may exhibit a concern with the driver seat and steering column moving to the saved memory position instead of the easy entry position when approaching or unlocking the vehicle with the key fob. This condition may occur after setting up a client profile and is due to the driver front seat module (DSM) software. Inform customers that they can continue to drive the vehicle and that engineering is currently working on revised DSM software for this condition. Monitor OASIS for additional information and schedule service appointments for customers once the repair becomes available.

- 1 reply

-

- 1

-

-

SSM 52381 - 2024 Nautilus - Inaccurate Clock, Google Map Not Displaying, And/Or Weather Not Updating Along With The Inability To Sign Into Google Automotive Services To Edit A Profile Some 2024 Nautilus vehicles may have a clock that is inaccurate and/or weather information may not be able to update along with the inability to sign-in to Google Automotive Services to update or edit a profile. During this time the Google Map may also not display in the panoramic display screen next to the speedometer. This may be due to a concern with the telematics control unit (TCU) module software. Inform customers that they can continue to drive the vehicle and that engineering is currently working on revised TCU module software for this concern. Monitor OASIS for additional information and schedule service appointments for customers once the repair becomes available. Note that it is normal for the Google Map to not appear in the panoramic display when in calm mode or when using the Waze app.

-

Link to Special Service Message 49931 - 2015-2021 Edge, 2016-2018 MKX, 2019-2021 Nautilus - Hood Bounce Or Flutter At High Speeds Good luck!

-

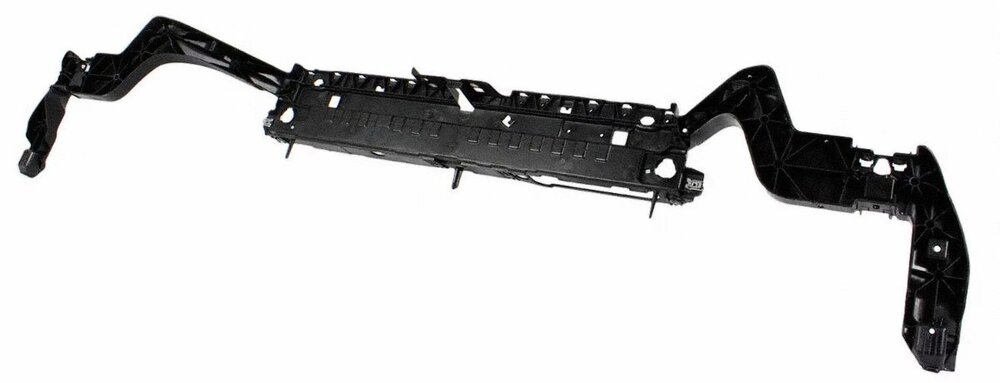

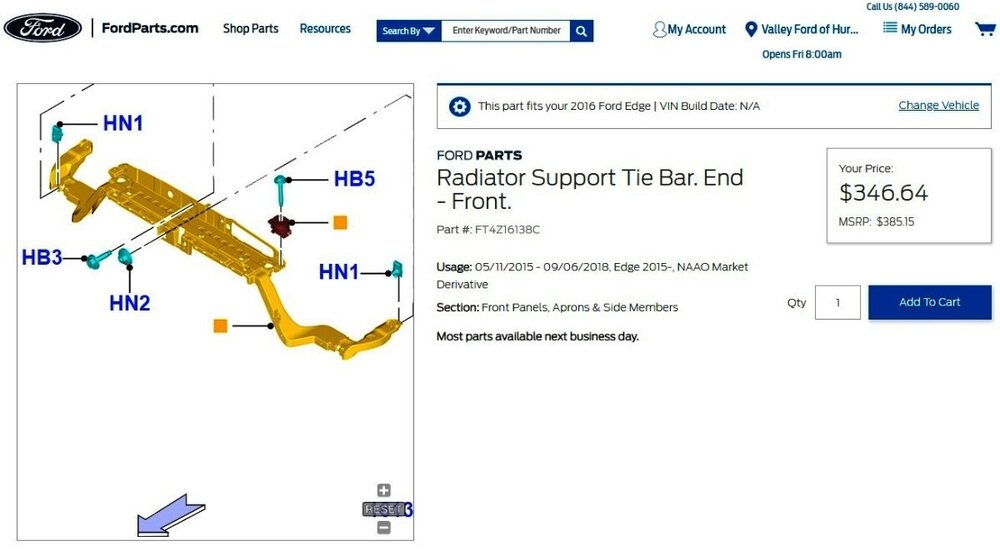

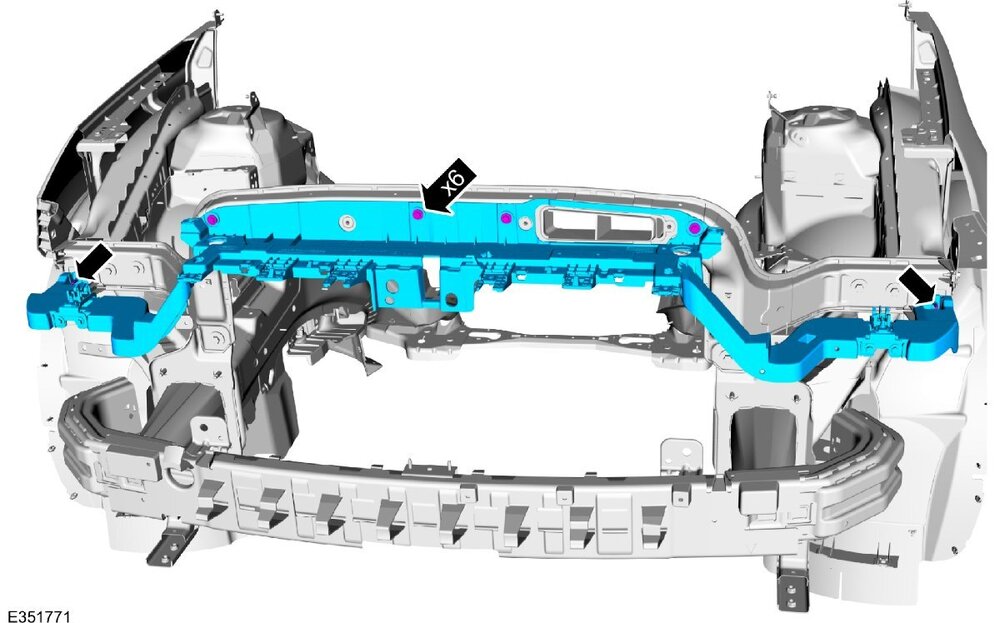

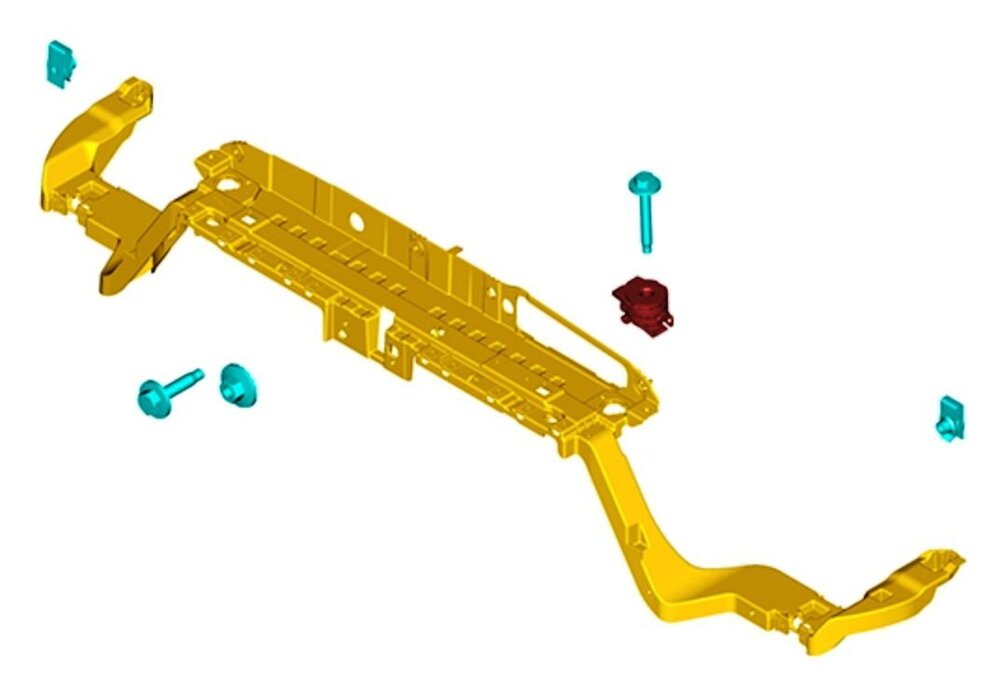

Link to this FordParts webpage Radiator Support Assembly - Removal and Installation - 2016 Edge Workshop Manual.pdf Headlamp Assembly - Removal and Installation - 2016 Edge Workshop Manual.pdf Hood Latch - Removal and Installation - 2016 Edge Workshop Manual.pdf Active Grille Shutter - Removal and Installation - 2016 Edge Workshop Manual.pdf Front Bumper Cover - Removal and Installation - 2016 Edge Workshop Manual.pdf Cooling Module - 2.0L EcoBoost - Removal and Installation - 2016 Edge Workshop Manual.pdf Good luck!

-

From the 2018 Edge Workshop Manual... Windshield Washer Pump - Removal and Installation - 2018 Edge Workshop Manual.pdf Fender Splash Shield - Removal and Installation - 2018 Edge Workshop Manual.pdf Good luck!